Online non-destructive monitoring method for low-temperature phase changes between tin and alloy of tin

A low-temperature phase transformation and alloy technology, which is applied to the measurement of electrical variables, the preparation of test samples, and measuring devices.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

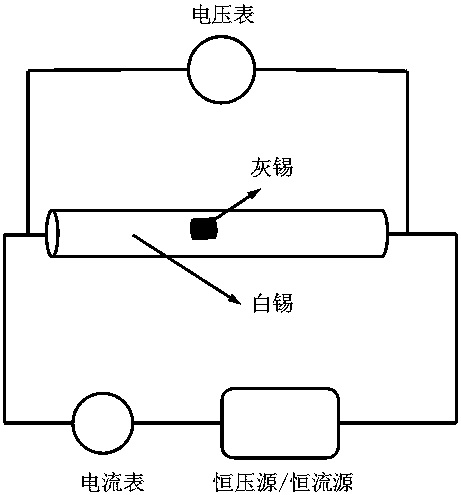

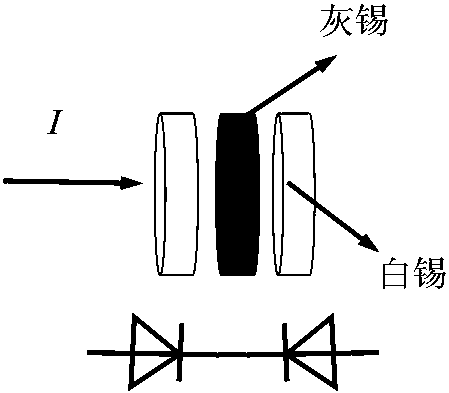

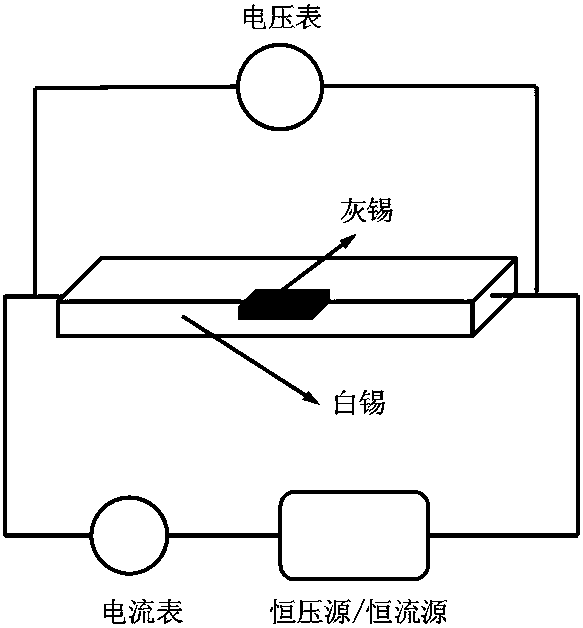

[0024] Specific implementation mode 1: This implementation mode records a method for on-line non-destructive monitoring of low-temperature phase transformation of tin and its alloys. The specific steps of the method are as follows:

[0025] Step 1: Draw the research sample into a filament with a diameter of 1~2mm or cold roll it into a thin plate with a thickness of 1~2mm. It should be noted that in order to increase the sensitivity of the sample resistance to the formation of gray tin, the filament The diameter of the thin plate or the thickness of the thin plate should be as small as possible, and the cold working makes the residual stress in the sample, which can promote the low-temperature phase transformation of Sn;

[0026] Step 2: Design the length of the filament or the length and width of the thin plate. It should be noted here that in order to increase the sensitivity of the test, the width of the thin plate should be as small as possible. Cut the sample to be tested...

specific Embodiment approach 2

[0031] Embodiment 2: A method for on-line non-destructive monitoring of low-temperature phase transformation of tin and its alloys described in Embodiment 1. In step 3, there are two types of low-temperature storage, which are as follows: (1) The sample is placed in the same low temperature environment of -200°C~0°C, and the sample to be tested is taken out every other day for circuit measurement, and the curve of current or voltage changes with time is drawn, and then put back into the low temperature environment after measurement. Measure 10 to 20 times; (2) Place the samples to be tested in different low temperature environments between -200°C and 0°C, for example, store the samples to be tested in each low temperature environment at the same interval at 25°C After the time, take a circuit measurement and plot the current or voltage versus temperature.

specific Embodiment approach 3

[0032] Embodiment 3: The method for on-line non-destructive monitoring of low-temperature phase transformation of tin and its alloys described in Embodiment 2, the same time is 10-20 days.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com