Preparation method of freeze-drying radix notoginseng superfine powder and product of freeze-drying radix notoginseng superfine powder

A technology of ultrafine powder and ultrafine pulverizer, which is applied in the field of preparation of freeze-dried Panax notoginseng superfine powder, can solve the problems of destroying Panax notoginseng, affecting the medicinal value of Panax notoginseng, unstable active ingredients, etc., and achieves a simple and sufficient processing method. The effect of drug efficacy and good business prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

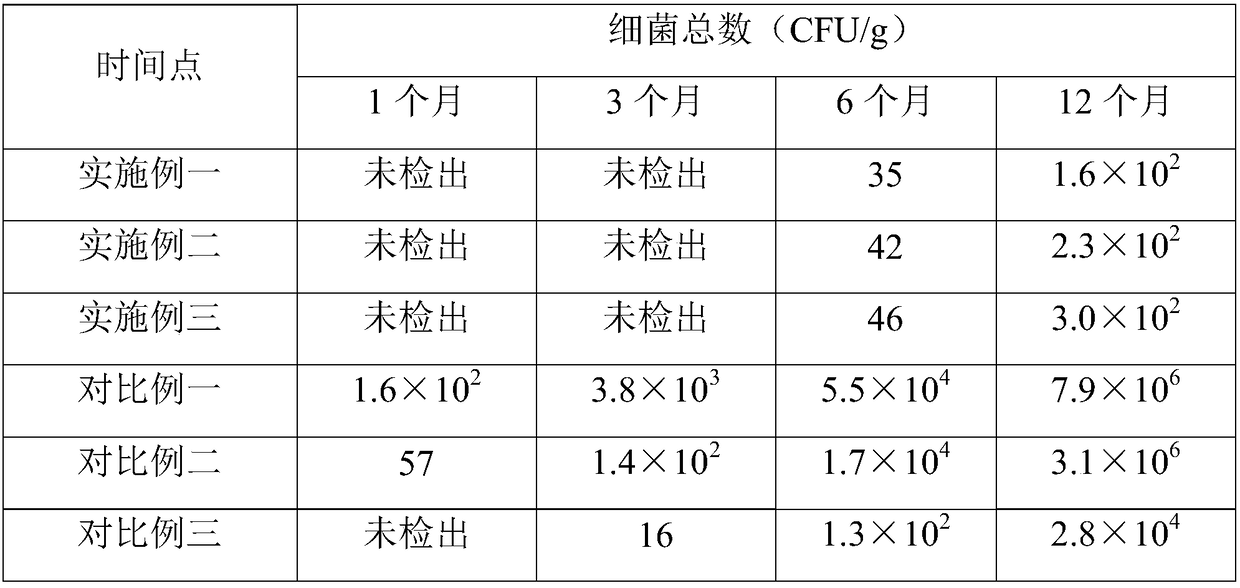

Examples

preparation example Construction

[0023] The invention provides a preparation method of freeze-dried Panax notoginseng superfine powder, comprising the following steps:

[0024] S1: Select the fresh notoginseng roots excavated before the flowers bloom in autumn, remove the fibrous roots and downy roots of the fresh notoginseng roots, and obtain the main root of notoginseng, clean the main root of notoginseng and remove the surface attachments, and then drain the water; , cleaning is to use a cleaning liquid to clean, the raw material components of the cleaning liquid are calculated in parts by weight, including: 30-50 parts by weight of ethanol, 400-500 parts by weight of water, 6-8 parts by weight of sodium benzoate, 5-10 parts by weight of tea saponin parts by weight, 7 to 9 parts by weight of sodium bicarbonate, 15 to 20 parts by weight of alkyl glycosides, 5 to 10 parts by weight of sodium chloride and 10 to 15 parts by weight of sorbitol;

[0025] S2: Put the drained Panax notoginseng main root in a freez...

Embodiment 1

[0032] The present embodiment provides a preparation method of freeze-dried Panax notoginseng superfine powder, comprising the following steps:

[0033] S1: Select the fresh notoginseng roots excavated before the flowers bloom in autumn, remove the fibrous roots and downy roots of the fresh notoginseng roots, and obtain the main root of notoginseng, clean the main root of notoginseng and remove the surface attachments, and then drain the water; , cleaning is to use a cleaning solution to clean, and the raw material components of the cleaning solution are calculated in parts by weight, including: 40 parts by weight of ethanol, 450 parts by weight of water, 7 parts by weight of sodium benzoate, 8 parts by weight of tea saponin, and 8 parts by weight of sodium bicarbonate part, 17 parts by weight of alkyl glucoside, 6 parts by weight of sodium chloride and 12 parts by weight of sorbitol;

[0034] S2: Put the drained Panax notoginseng root in the first environment for 75 hours and...

Embodiment 2

[0040] The present embodiment provides a preparation method of freeze-dried Panax notoginseng superfine powder, comprising the following steps:

[0041]S1: Select the fresh notoginseng roots excavated before the flowers bloom in autumn, remove the fibrous roots and downy roots of the fresh notoginseng roots, and obtain the main root of notoginseng, clean the main root of notoginseng and remove the surface attachments, and then drain the water; , cleaning is to use a cleaning solution to clean, the raw material components of the cleaning solution are calculated by weight, including: 30 parts by weight of ethanol, 500 parts by weight of water, 6 parts by weight of sodium benzoate, 10 parts by weight of tea saponin, and 7 parts by weight of sodium bicarbonate part, 20 parts by weight of alkyl glucoside, 5 parts by weight of sodium chloride and 15 parts by weight of sorbitol;

[0042] S2: Put the drained Panax notoginseng root in the first environment for 70 hours and in the secon...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com