Winding equipment for I-shaped magnetic core and winding method thereof

A winding device and I-shaped technology are applied in the field of I-shaped magnetic core winding equipment and its winding, which can solve the problem that it is not suitable for large-scale production of enterprises, the winding effect cannot be guaranteed, and the production cost is high. Not inferior to other problems, to achieve the effect of improving the overall utilization rate, fast moving speed, and strong scale controllability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

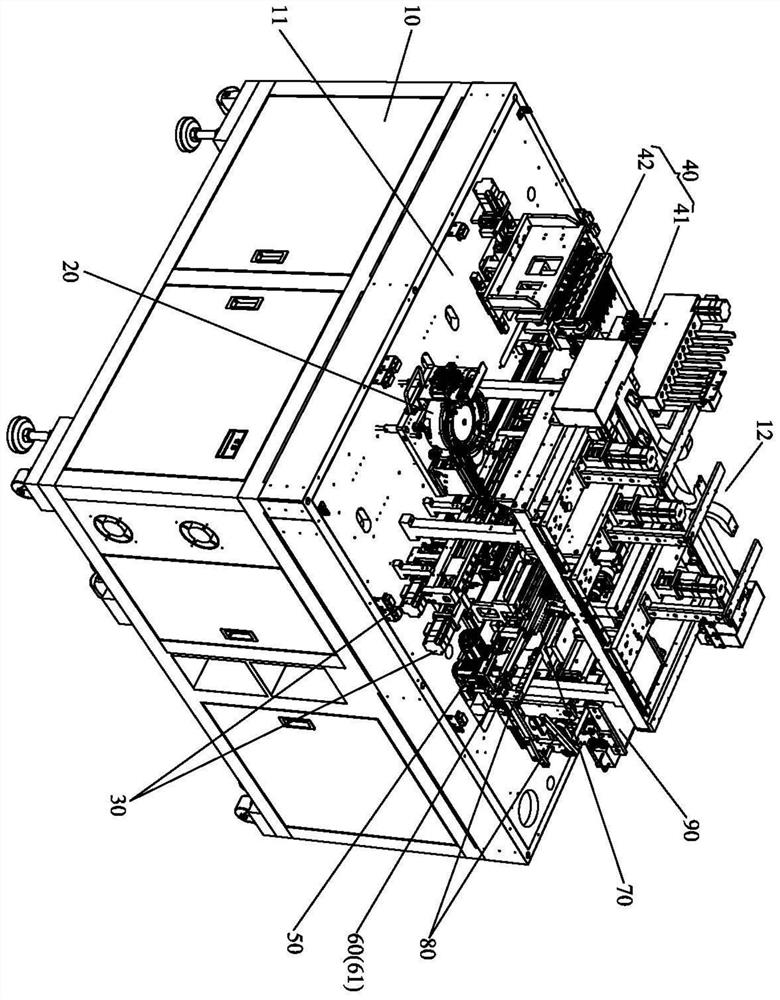

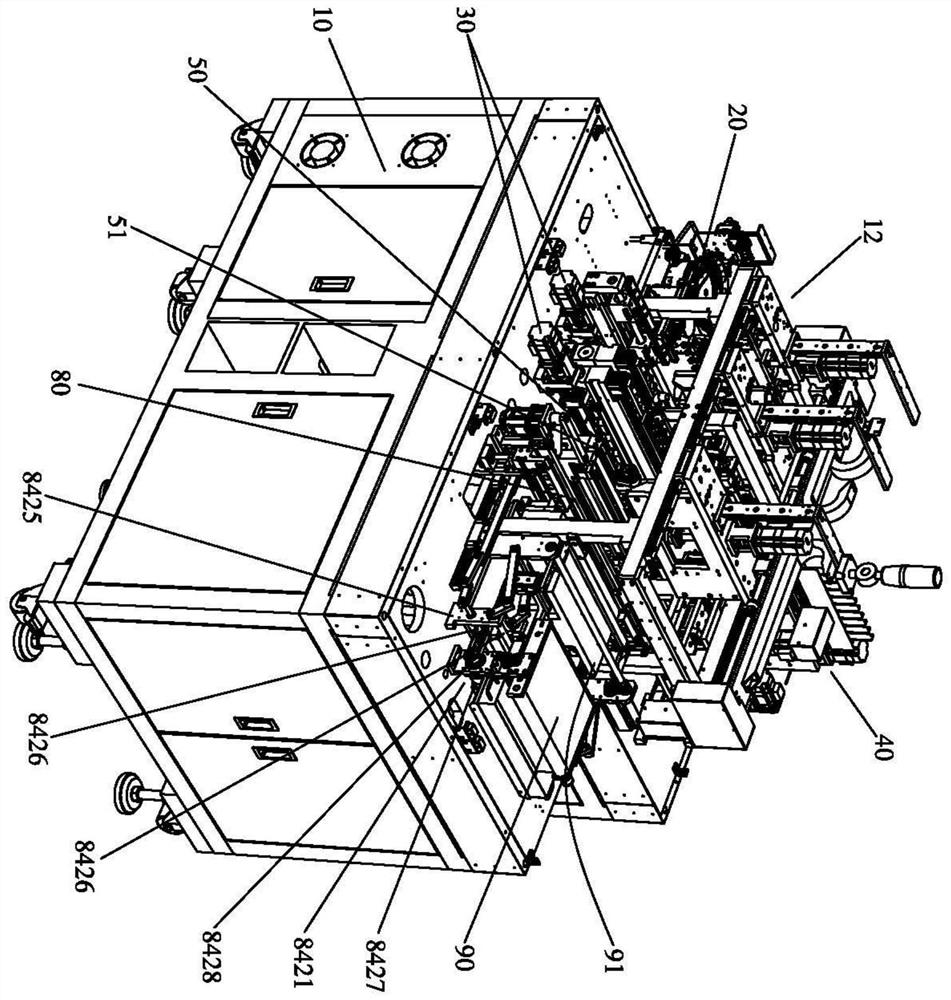

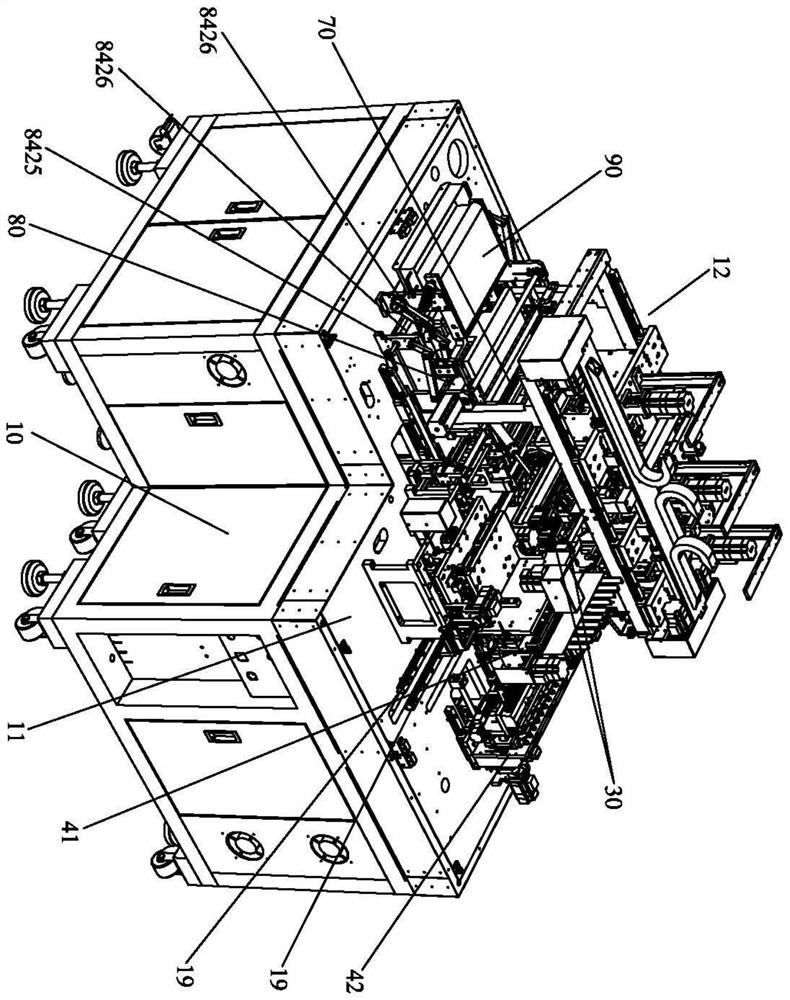

[0118] The present invention as Figure 1 to Figure 15 As shown, a winding device for an I-shaped magnetic core and a winding method thereof include a frame 10, a vibrating feeding and distributing mechanism 20, a double-spindle feeding mechanism 30, a winding mechanism 40, and a flux directional coating mechanism 50. Preheating mechanism 60, flattening mechanism 70, tin dipping and scraping device 80, and discharge mechanism 90, wherein:

[0119]The frame 10 has a workbench 11 on the upper surface, and the workbench 11 is provided with a material-moving rack 12 for material suction and transfer. The above-mentioned mechanisms are located on the workbench 11 and below the material-moving rack 12; The material shifting frame 12 includes a suspension 13 and a plurality of support beams 14 that can slide horizontally on the suspension 13, and a plurality of suction nozzles 15 and a mechanism for driving the suction nozzles 15 to rise and fall are respectively arranged side by sid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com