Control device for rotationally and continuously producing alloy and equipment thereof

A control device and a technology for producing alloys, applied in metal processing equipment, safety devices, casting equipment, etc., can solve the problems of long production cycle, high mold cost, low production efficiency, etc., and achieve short production cycle and high control precision , the effect of high production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further described below in conjunction with embodiment.

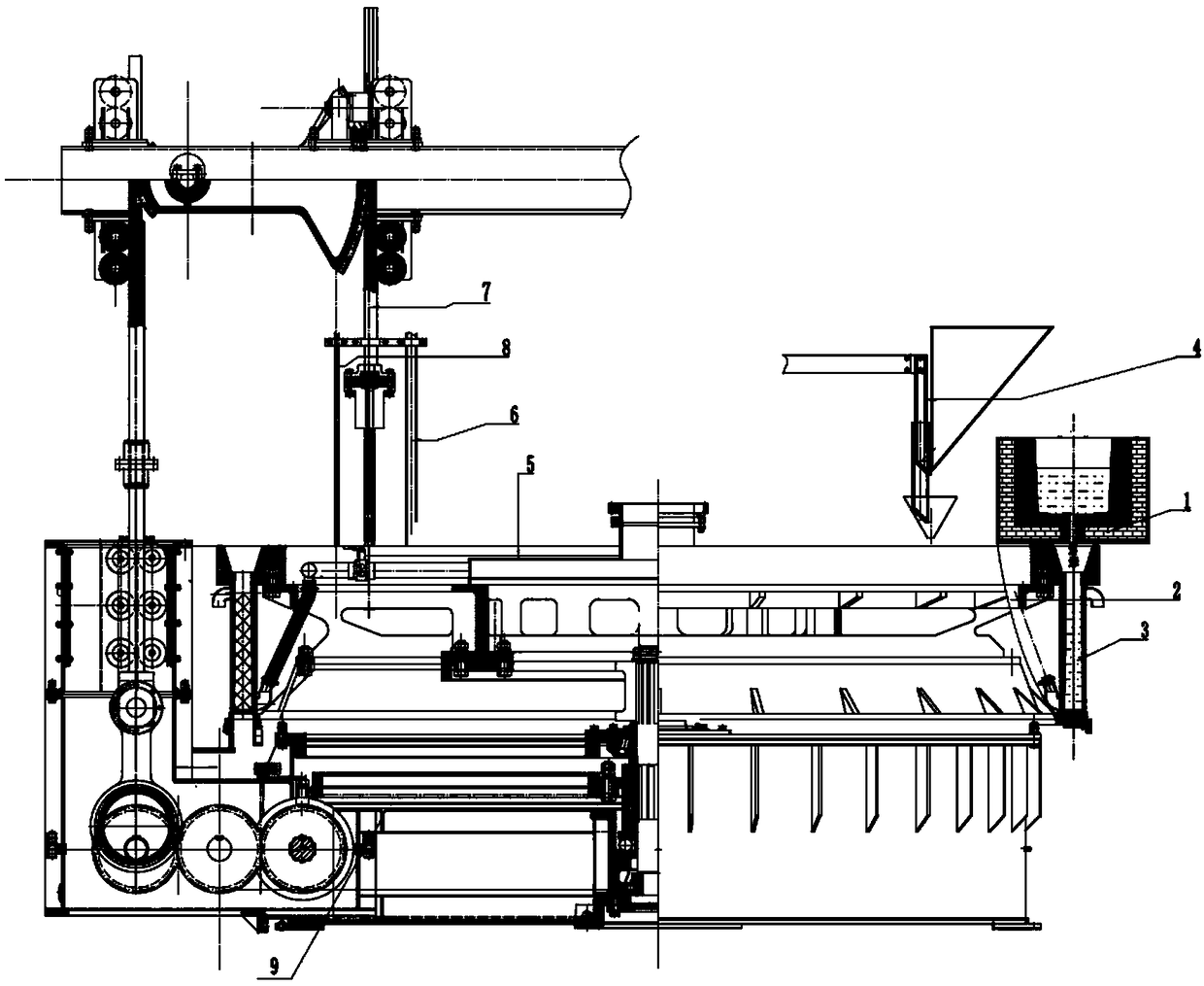

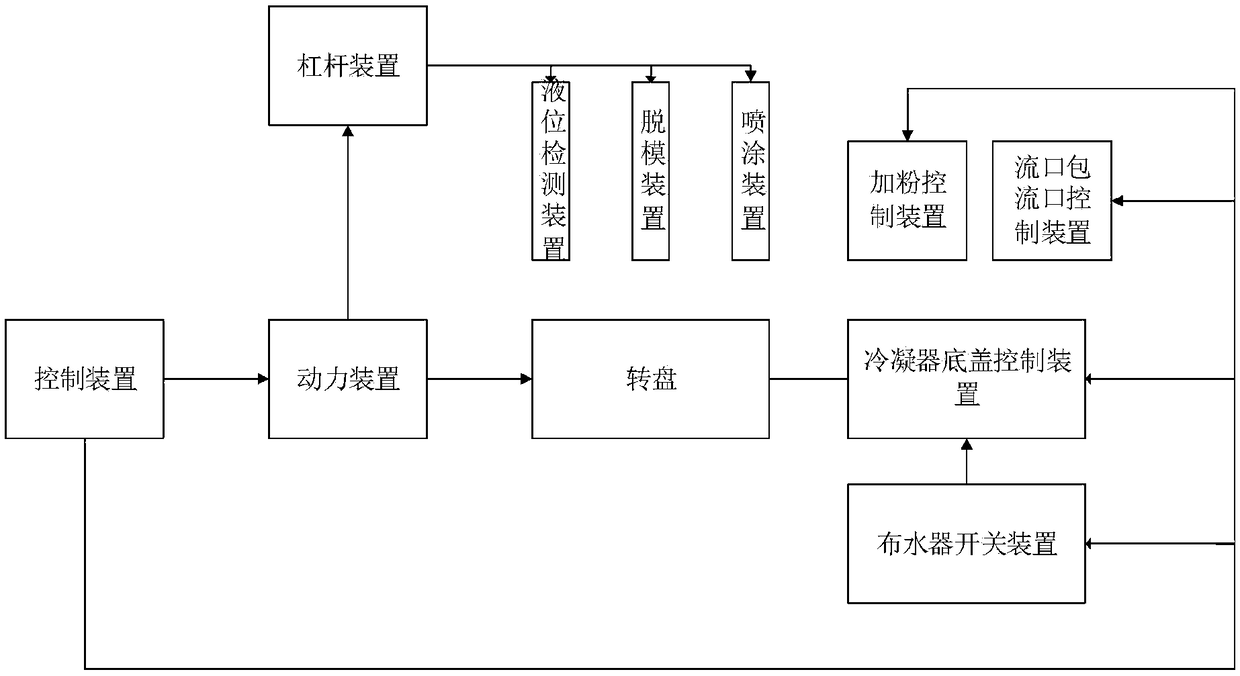

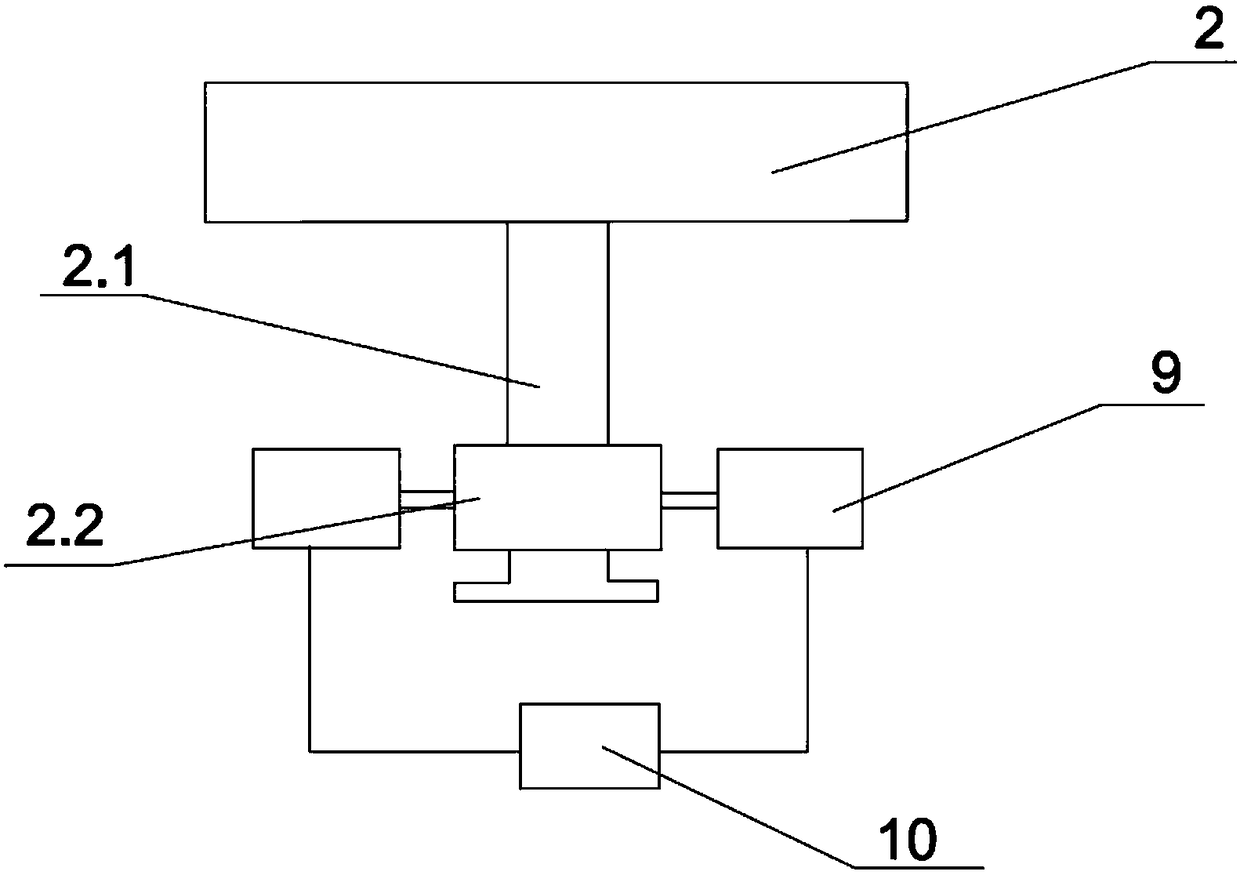

[0028] Such as figure 2 As shown, a control device for rotary continuous production of alloys, including a control device, a power device, a lever device, a water distributor switch device, a powder feeding control device, a condenser bottom cover control device and a spout bag spout control device.

[0029] The output end of the control device is respectively connected with the power device, the switch device of the water distributor, the control device of the bottom cover of the condenser and the flow port control device of the orifice bag. The control device includes a microprocessor, a clock circuit and a motor drive circuit, the clock circuit is connected with the microprocessor, and the microprocessor is connected with the motor through the motor drive circuit. The microprocessor uses STM32 series single-chip microcomputer chips, and the motor drive circuit uses a multi-chann...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com