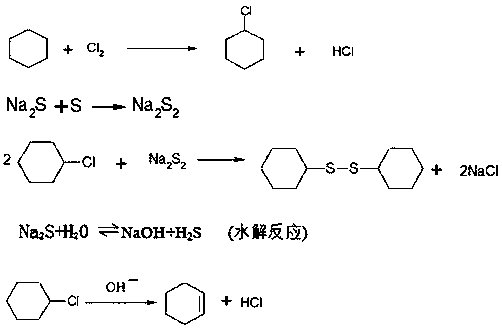

Method for continuously synthesizing scorch retarder CTP intermediate (dicyclohexyl disulphide)

A technology of dicyclohexyl disulfide and intermediates, which is applied in the field of raw material synthesis of anti-scorch agent, can solve the problems of large investment in tail gas recondensation, high requirements for rectification equipment, large heat consumption, etc., so as to reduce equipment investment and heat consumption. Large, energy-saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

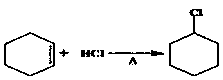

[0042] 1. Take 800kg of commercially available cyclohexene (purity ≥ 99.00%) and put it into the synthesis kettle, add 3000L of hydrochloric acid with a concentration of 28-32% into the synthesis kettle, stir and heat, raise the temperature to 95°C, react for 4 hours, and turn it on after the reaction is completed Circulating water valve cools down the synthetic kettle, stop cooling when the temperature drops below 60°C, turn off the stirring, let stand for liquid separation, the water phase obtained by liquid separation is hydrochloric acid aqueous solution, and put the separated hydrochloric acid aqueous solution into the hydrochloric acid intermediate tank for storage. The oil phase obtained by liquid separation is the crude chlorocyclohexane, which is put into the alkali washing tank and washed with a large amount of saturated sodium bicarbonate solution. Neutralize all the hydrochloric acid, then let it stand for stratification, discharge the sodium bicarbonate lotion in t...

Embodiment 2

[0046] 1. Take 800kg of commercially available cyclohexene (purity ≥ 99.00%) into the synthesis kettle, add 2900L of hydrochloric acid with a concentration of 28-32% into the synthesis kettle, stir and heat, raise the temperature to 106°C, react for 12 hours, and turn it on after the reaction is completed Circulating water valve cools down the synthetic kettle, stop cooling when the temperature drops below 60°C, turn off the stirring, let stand for liquid separation, the water phase obtained by liquid separation is hydrochloric acid aqueous solution, and put the separated hydrochloric acid aqueous solution into the hydrochloric acid intermediate tank for storage. The oil phase obtained by liquid separation is the crude chlorocyclohexane, which is put into the alkali washing tank and washed with a large amount of saturated sodium bicarbonate solution. Neutralize all the hydrochloric acid, then let it stand for stratification, discharge the sodium bicarbonate lotion in the lower ...

Embodiment 3

[0050] 1. Take 800kg of commercially available cyclohexene (purity ≥ 99.00%) into the synthesis kettle, drop 2500L of hydrochloric acid with a concentration of 28-32% into the synthesis kettle, and complete the dropwise addition in 3 hours. After the addition, stir and heat, and raise the temperature to 105 ℃, react for 10 hours, after the reaction, open the circulating water valve to cool down the synthesis kettle, stop the cooling when the temperature drops below 60°C, turn off the stirring, stand for liquid separation, the water phase obtained by liquid separation is hydrochloric acid aqueous solution, and the separated hydrochloric acid The aqueous solution enters the hydrochloric acid intermediate tank for storage for later use. The oil phase obtained by liquid separation is the crude product of chlorocyclohexane. The crude product is put into the alkali washing tank and washed with a large amount of saturated sodium bicarbonate solution. The material is recycled and washe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com