Steel for wear-resistant steel ball and rolling processing method of the steel ball

A processing method and technology of wear-resistant steel, applied in the direction of manufacturing tools, furnaces, heat treatment equipment, etc., can solve the problems of easy breakage, low cost, poor wear resistance, etc., to reduce labor intensity, high production efficiency, and steel ball quality. high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-6

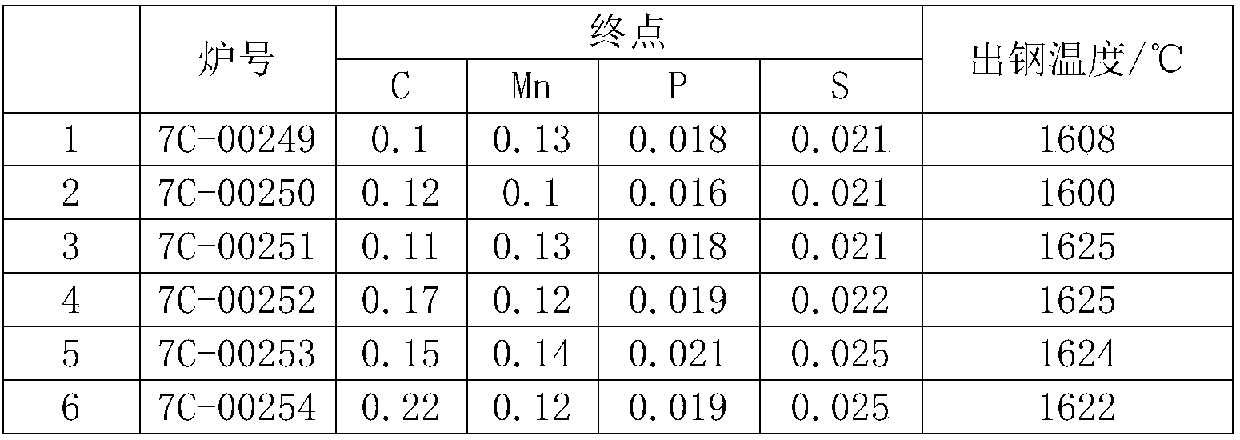

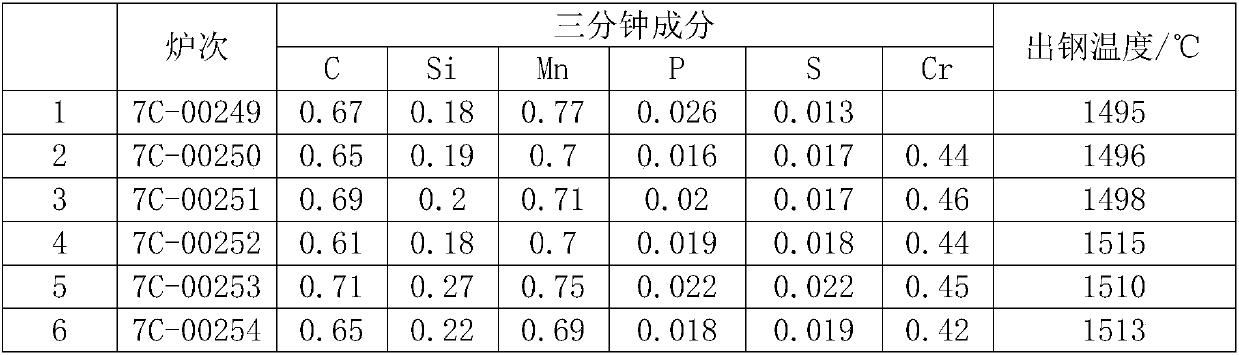

[0082] Chemical composition and mass percentage thereof of table 7 embodiment 1-6

[0083]

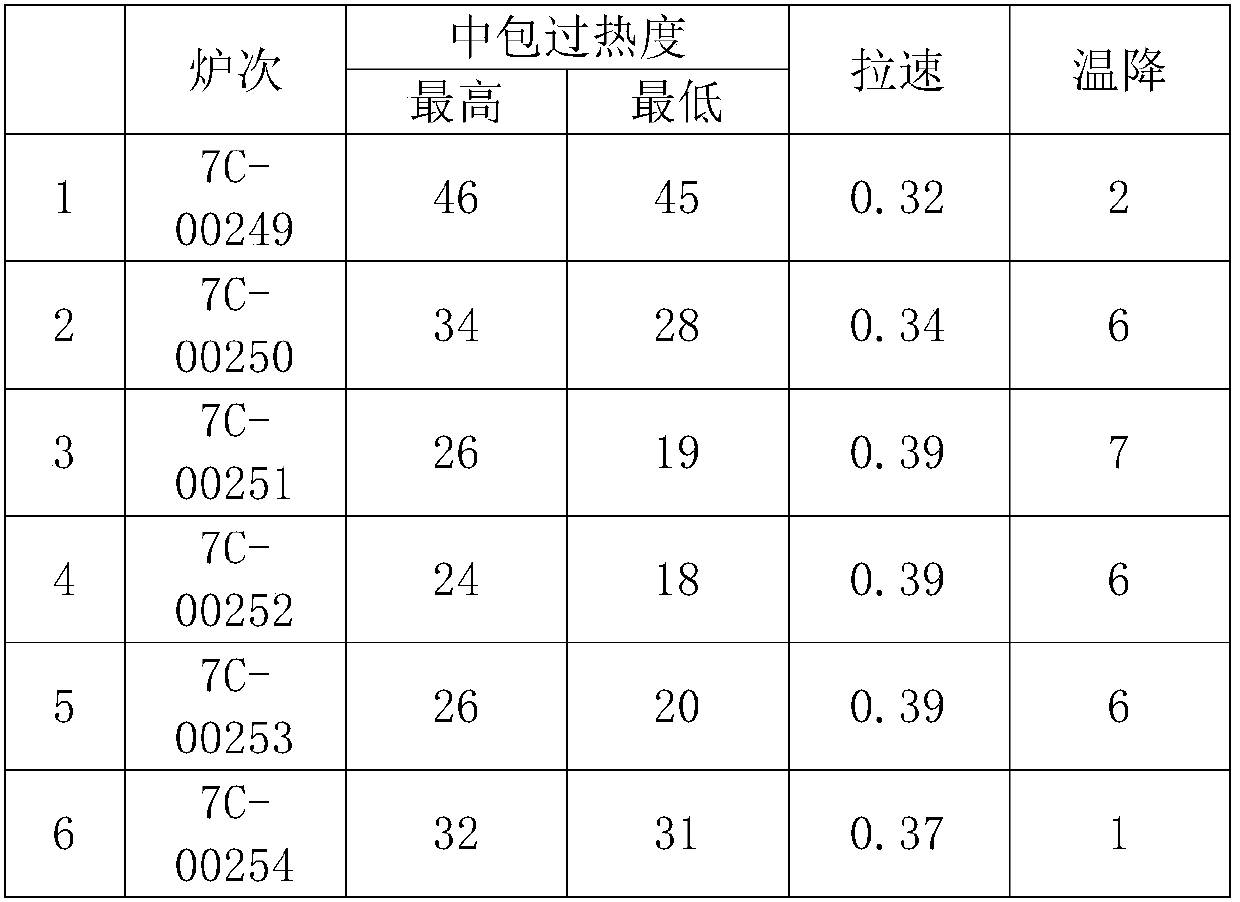

[0084] 3. Test results: as shown in Table 8-12,

[0085] 1. According to CB / T226-1991 "Steel Low-magnification Microstructure and Defect Acid Intrusion Test Method", the low-magnification structure meets the standard requirements;

[0086] 2. According to CB / T224-2008 "Measurement of Decarburization Depth of Steel", the structure is normal sorbite and pearlite, the decarburization efficiency is 1.5% D, and all indicators meet the standard requirements;

[0087] 3. [O] content meets the standard requirements;

[0088] 4. As of February 10, 2017, track the passing rate of this batch of materials for warehousing inspection, eliminate defects such as rolling defects and scarring, and the comprehensive passing rate is 99.3%;

[0089] 5. As shown in Table 12, since the development of wear-resistant steel balls began in February, the overall quality has been stable, the production inspec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com