Melt spinning technology

A melt spinning and crafting technology, applied in the field of spinning, can solve disadvantages and other problems, and achieve the effects of easy operation, high spinning efficiency and simple equipment structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

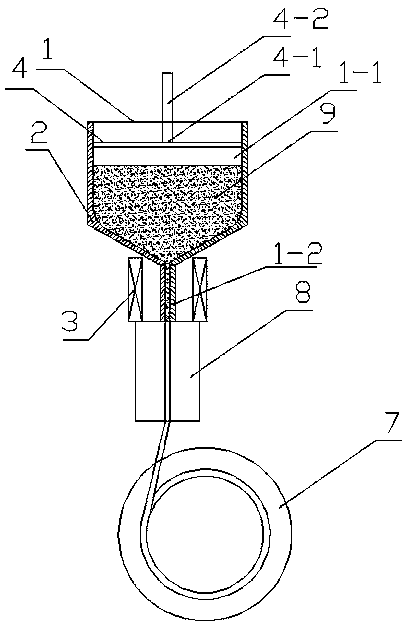

Image

Examples

Embodiment 1

[0048] A melt-spinning process is a melt-spinning process, and the melt is obtained as follows:

[0049] Step 1, at 50°C, a-Al 2 o 3 The nanoparticles are placed in the aluminum sulfate solution with a concentration of 0.5mol / L to obtain a dispersion, and the pH of the solution is adjusted to 6~7; add magnetic material particles (Fe particles, average particle size 2 microns) to the dispersion, and after the addition is completed, Add ammonium bicarbonate solution with a concentration of 1.5mol / L dropwise into it, the volume of the aluminum salt solution and the ammonium bicarbonate solution is 1:1; then the resulting mixture is spray-dried, and the dried particles are roasted, The calcination temperature is 450°C to obtain a-Al 2 o 3 coated magnetic material particles, wherein, a-Al 2 o 3 The ratio of nanoparticles to inorganic aluminum salt solution is 1g:500mL;

[0050] Step 2, polyphenylene sulfide powder, step 1 obtained a-Al 2 o 3 The coated magnetic material par...

Embodiment 2

[0053] A melt-spinning process is a melt-spinning process, and the melt is obtained as follows:

[0054] Step 1, at 50°C, a-Al 2 o 3 The nanoparticles are placed in the aluminum sulfate solution with a concentration of 0.5mol / L to obtain a dispersion, and the pH of the solution is adjusted to 6~7; add magnetic material particles (Fe particles, average particle size 2 microns) to the dispersion, and after the addition is completed, Add ammonium bicarbonate solution with a concentration of 1.5mol / L dropwise into it, the volume of the aluminum salt solution and the ammonium bicarbonate solution is 1:1; then the resulting mixture is spray-dried, and the dried particles are roasted, The calcination temperature is 450°C to obtain a-Al 2 o 3 coated magnetic material particles, wherein, a-Al 2 o 3 The ratio of nanoparticles to inorganic aluminum salt solution is 1g:500mL;

[0055] Step 2, polyphenylene sulfide powder, step 1 obtained a-Al 2 o 3 The coated magnetic material par...

Embodiment 3

[0058] A melt-spinning process is a melt-spinning process, and the melt is obtained as follows:

[0059] Step 1, at 80°C, the a-Al 2 o 3 The nanoparticles are placed in the inorganic aluminum salt solution with a concentration of 1mol / L to obtain a dispersion, and the pH of the solution is adjusted to 6~7; the magnetic material particles are added to the dispersion, and the concentration of 2mol / L is added dropwise to the dispersion. L of ammonium bicarbonate solution, the volume of the aluminum salt solution and the ammonium bicarbonate solution is 1:1; then the resulting mixture is spray-dried, and the dried particles are roasted at a roasting temperature of 500°C to obtain a-Al 2 o 3 coated magnetic material particles, wherein, a-Al 2 o 3 The ratio of nanoparticles to inorganic aluminum salt solution is 1g:700mL;

[0060] Step 2, the a-Al obtained in step 1 2 o 3 The coated magnetic material particles are mixed with other fiber raw materials and obtained by melting. ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com