Hard rock body non-blasting tunneling device

A kind of rock mass and hard technology, applied in the field of hard rock mass excavation without guns, can solve the problems of low rock breaking efficiency, high thrust, low safety, etc., to improve rock breaking ability and efficiency, reduce overall size, The effect of simple and compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

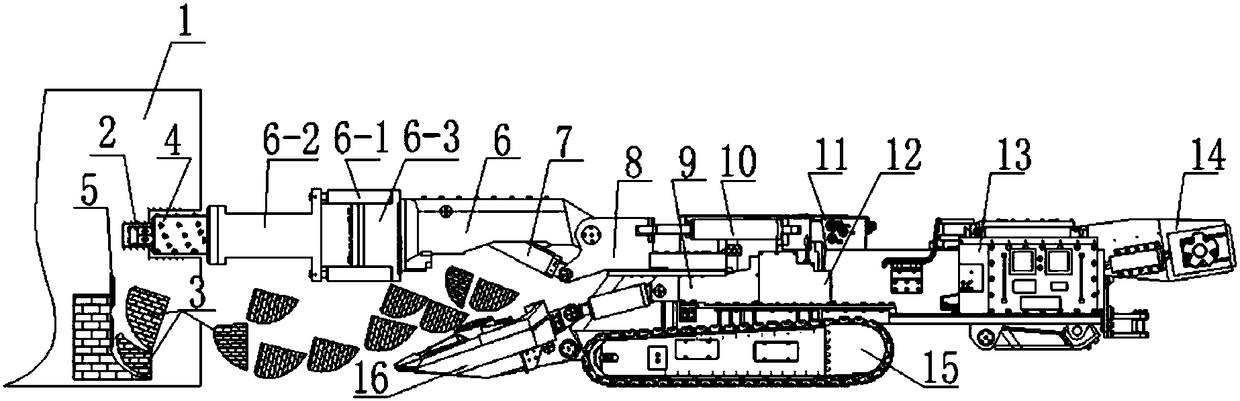

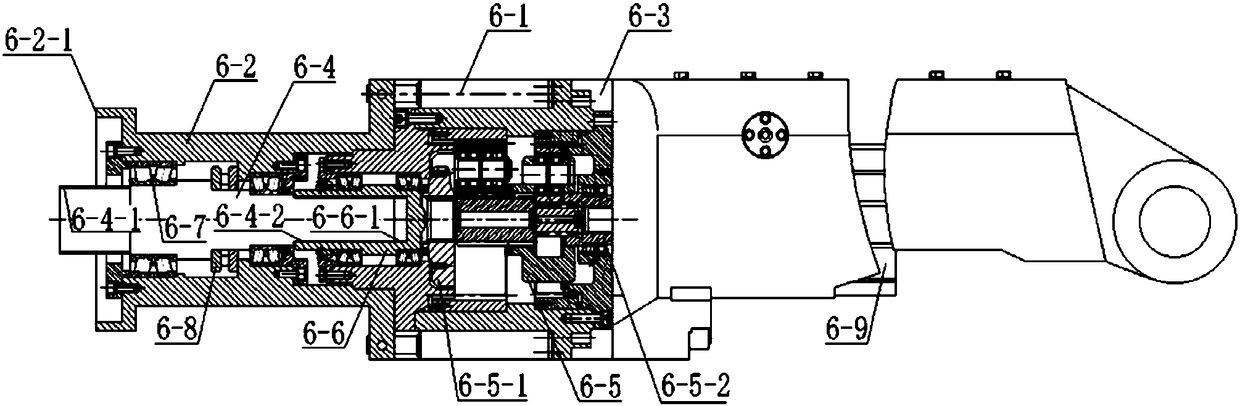

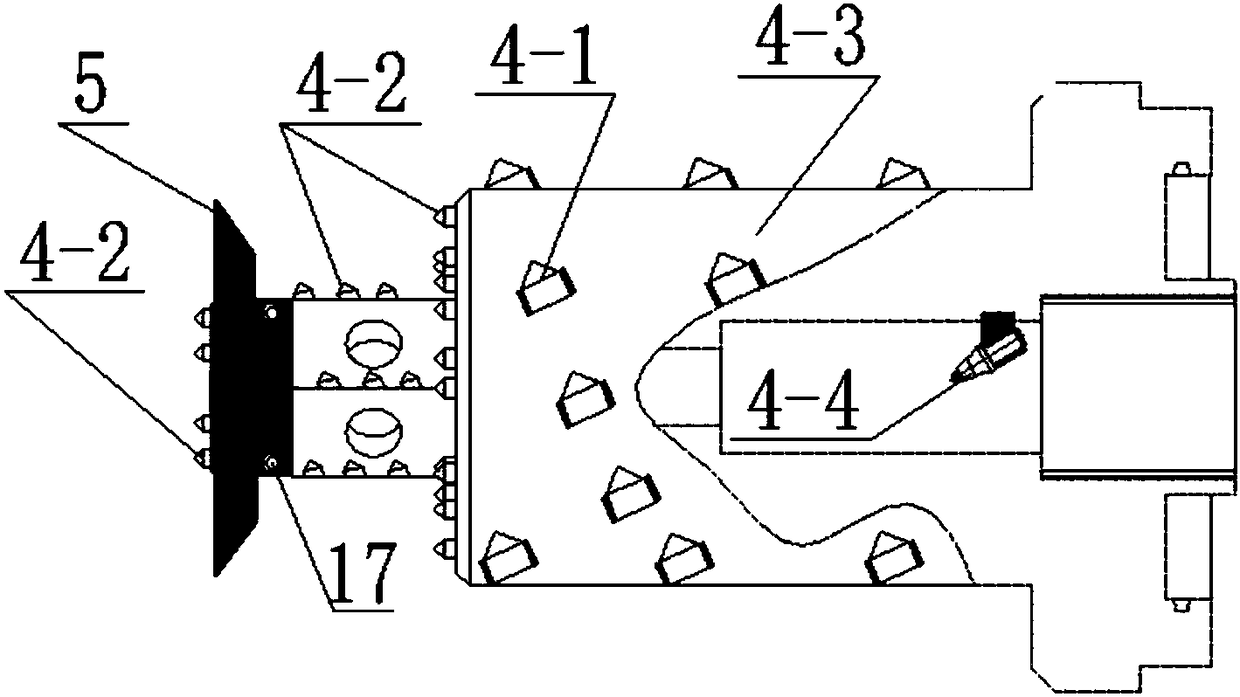

[0022] Embodiment 1: as Figures 1 to 2 As shown, the hard rock mass excavation equipment without guns of the present invention mainly consists of a stepped drill bit 4, a circular hob 5, a power cantilever 6, a lifting cylinder 7, a slewing frame 8, a body frame 9, a swing cylinder 10, a hydraulic system 11, Control console 12, electric control box 13, scraper machine 14, running mechanism 15, shovel loading device 16, U-shaped pin 17 form. The body frame 9 is used as a connecting link for other parts of the excavation equipment, connected or equipped with the slewing frame 8, the hydraulic system 11, the console 12, the electric control box 13, the scraper machine 14, etc.; the traveling mechanism 15 carries the body frame 9. It can make the excavation equipment move as a whole; the power cantilever 6 provides rotational torque for the stepped drill bit 4 and the circular hob 5 to break rock, and the rear end of the outer casing 6-3 of the power cantilever 6 passes through t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com