Semi-superjunction fs IEGT structure and its fabrication method

A manufacturing method, semi-superjunction technology, applied in semiconductor/solid-state device manufacturing, semiconductor devices, electrical components, etc., can solve problems such as large short-circuit current, reduced forward conduction voltage drop, poor short-circuit capability, etc., and achieve turn-off time Effects of increased, reduced conduction voltage drop, and high short-circuit capability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be described in detail below in combination with specific embodiments.

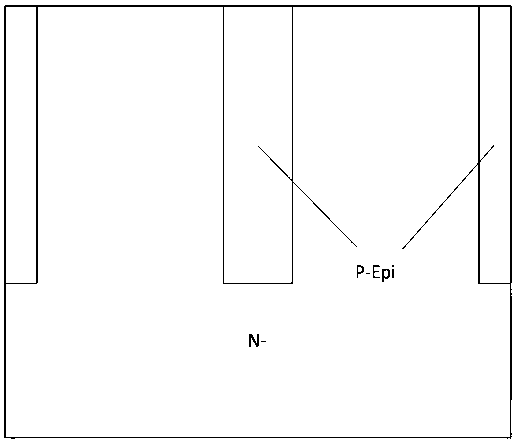

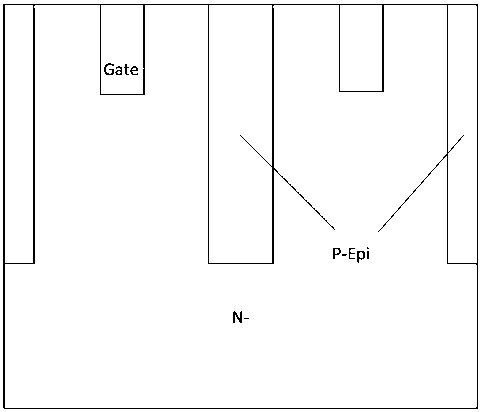

[0030] The field-stop IGBT (Field-Stop IGBT, FS IGBT) can achieve a good compromise between on-state loss and device withstand voltage as well as on-state loss and switching loss. The electron injection enhanced gate transistor (Injection Enhancement Gate Transistor, IEGT) adopts a dummy trench structure, which produces an electron injection enhancement effect, reduces the device conduction voltage drop, and reduces the channel density, which can improve the short circuit capability of the device. Semi-superjunction IEGT applies superjunction theory to IGBT chip design, which can reduce the thickness of the drift region and reduce the conduction voltage drop and switching loss at the same time.

[0031] The existing FS IGBT or IEGT structure is optimized in some parameters such as breakdown voltage, conduction voltage drop, switching loss and short-circuit capability. The...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com