Preparation method of MOFs nano material supporting nano metal particles

A technology of nano metal particles and nano materials, applied in the field of preparation of MOFs nano materials, can solve the problems of reduced catalytic activity, easy agglomeration of nanoparticles, hindered mass transfer process, etc., to improve stability and selectivity, and mild and controllable conditions. , the effect of cheap and easy-to-obtain raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

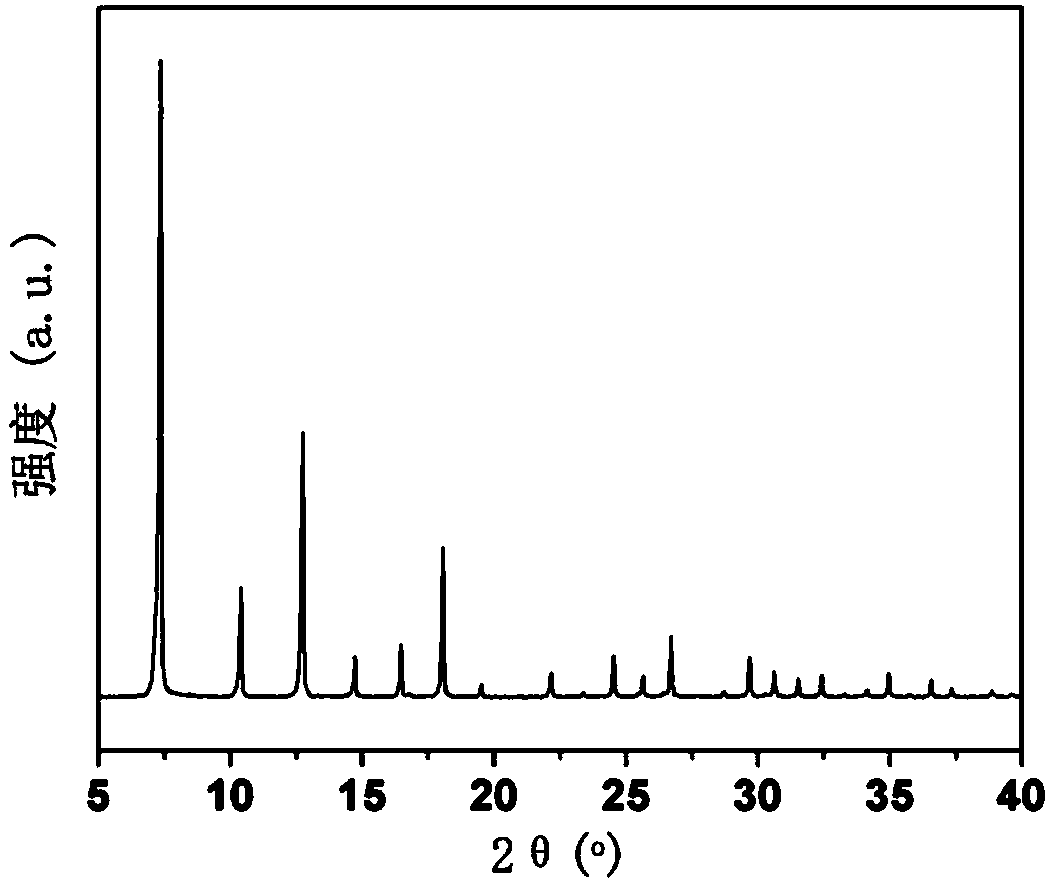

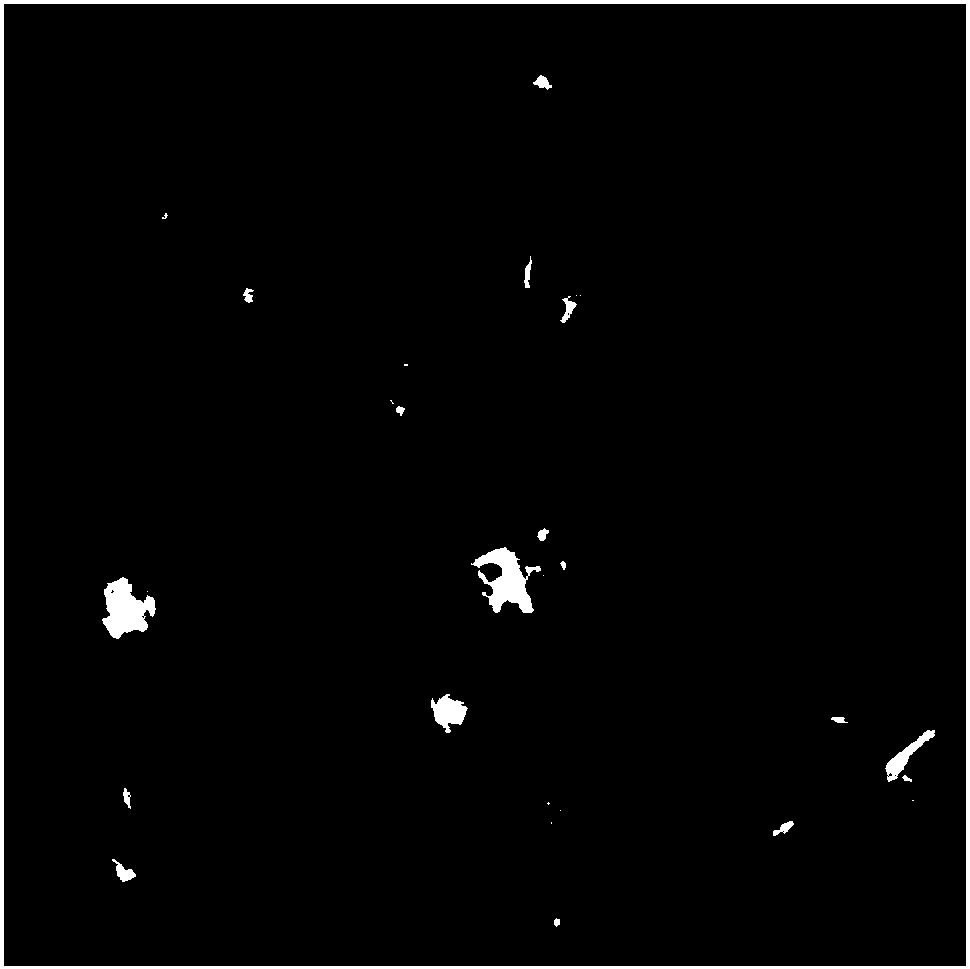

Embodiment 1

[0023] Mix 40mL of zinc nitrate methanol solution with a concentration of 0.025mol / L and 40mL of 2-methylimidazole methanol solution with a concentration of 0.1mol / L, mix and stir evenly, let stand at room temperature for 12h, wash with ethanol and dry by centrifugation. Disperse the solid powder obtained in the previous step in 10 mL of methanol solution, add 2.5 mL of 2-methylimidazole methanol solution with a concentration of 0.8 mol / L containing Pt nanoparticles and 2.5 mL of cobalt nitrate methanol solution with a concentration of 0.05 mol / L, and mix After stirring evenly, react at 100° C. for 12 h, wash with ethanol and dry by centrifugation. Disperse the solid powder obtained in the previous step in 15 mL of methanol solution, add 2.5 mL of 2-methylimidazole methanol solution with a concentration of 0.02 mol / L and 2.5 mL of zinc nitrate methanol solution with a concentration of 0.01 mol / L, mix and stir evenly After reacting at 105° C. for 6 h, wash with ethanol and cent...

Embodiment 2

[0027] Mix 40 mL of zinc nitrate methanol solution with a concentration of 0.035 mol / L and 40 mL of 2-methylimidazole methanol solution with a concentration of 0.1 mol / L, stir evenly, let stand at room temperature for 12 h, wash with ethanol and dry by centrifugation. Disperse the solid powder obtained in the previous step in 10 mL of methanol solution, add 2.5 mL of 2-methylimidazole methanol solution containing Pt nanoparticles at a concentration of 0.8 mol / L and 2.5 mL of cobalt nitrate methanol solution with a concentration of 0.2 mol / L, and mix After stirring evenly, react at 100° C. for 12 h, wash with ethanol and dry by centrifugation. Disperse the solid powder obtained in the previous step in 15 mL of methanol solution, add 2.5 mL of 2-methylimidazole methanol solution with a concentration of 0.02 mol / L and 2.5 mL of zinc nitrate methanol solution with a concentration of 0.03 mol / L, mix and stir evenly After reacting at 105° C. for 4 h, wash with ethanol and centrifuga...

Embodiment 3

[0030] Mix 40 mL of zinc nitrate methanol solution with a concentration of 0.045 mol / L and 40 mL of 2-methylimidazole methanol solution with a concentration of 0.1 mol / L, mix and stir evenly, let stand at room temperature for 12 hours, wash with ethanol and dry by centrifugation. Disperse the solid powder obtained in the previous step in 10 mL of methanol solution, add 2.5 mL of 2-methylimidazole methanol solution with a concentration of 0.8 mol / L containing Pt nanoparticles and 2.5 mL of cobalt nitrate methanol solution with a concentration of 0.1 mol / L, and mix After stirring evenly, react at 100° C. for 12 h, wash with ethanol and dry by centrifugation. Disperse the solid powder obtained in the previous step in 15 mL of methanol solution, add 2.5 mL of 2-methylimidazole methanol solution with a concentration of 0.02 mol / L and 2.5 mL of zinc nitrate methanol solution with a concentration of 0.02 mol / L, mix and stir evenly After reacting at 100° C. for 8 h, wash with ethanol ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com