Oil tank cleaning robot with squirrel-cage structure

A squirrel-cage and robot technology, applied in the direction of manipulators, cleaning hollow objects, chemical instruments and methods, etc., can solve the problems of endangering the health of workers and manual entry, etc., achieve good reverse control performance, reduce selection, and reduce the center Effect of pitch and gear ratio

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0028] The present invention will be further described below in conjunction with accompanying drawing:

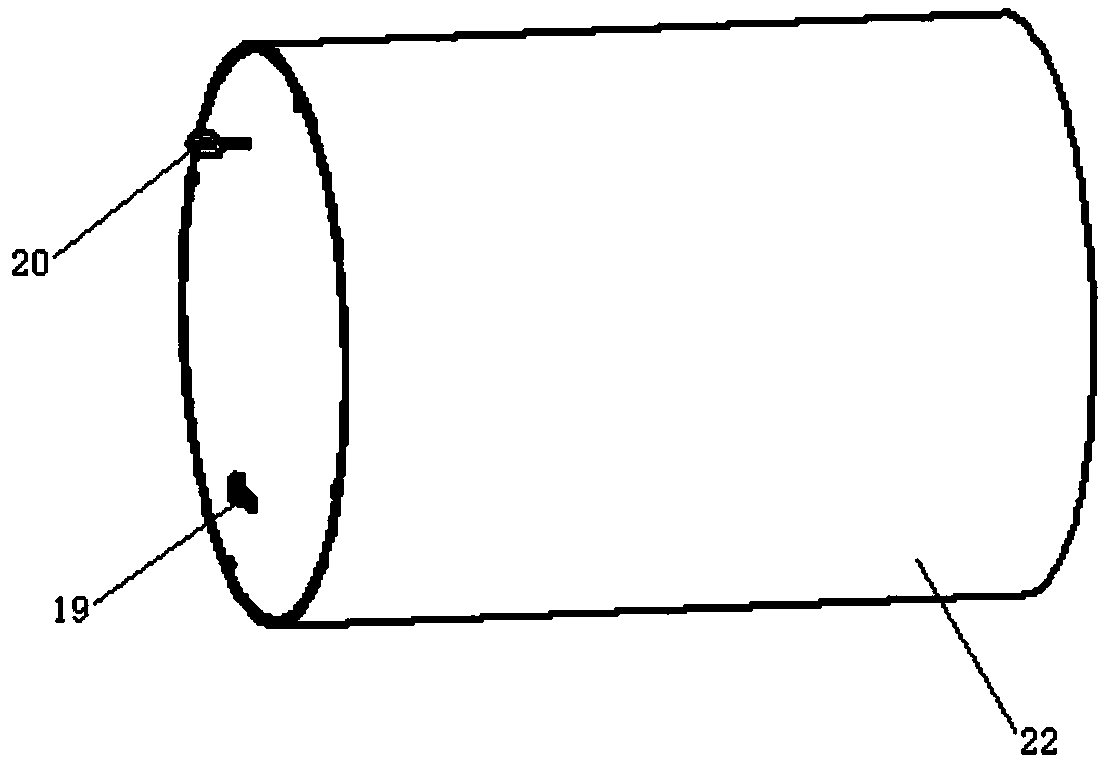

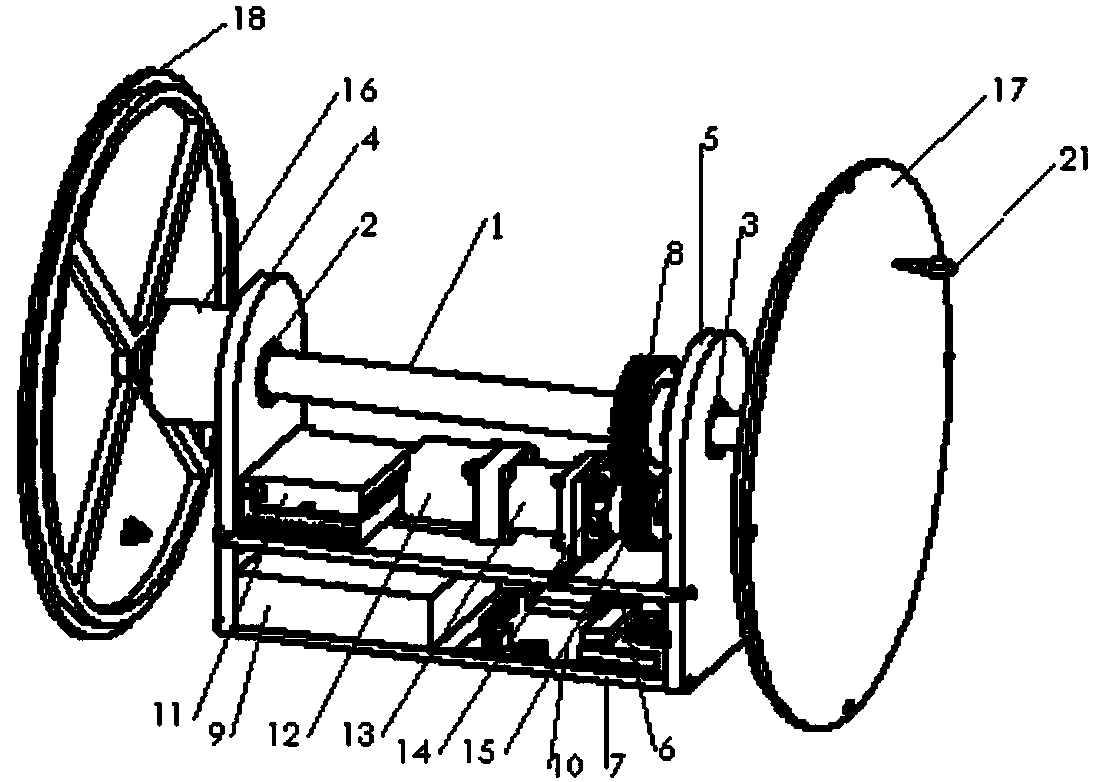

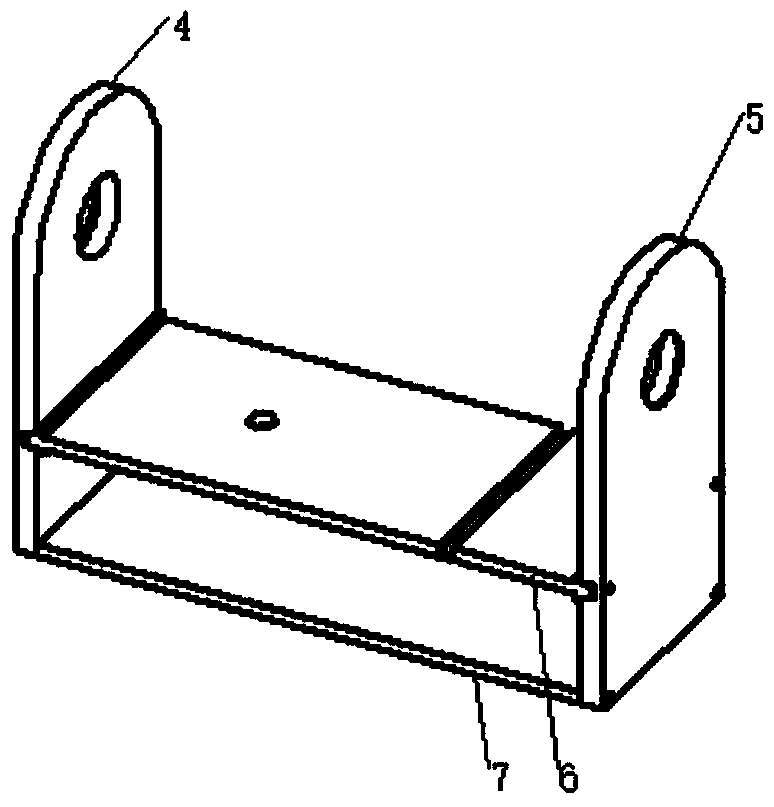

[0029] Such as figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 As shown, a cylinder cleaning robot with a squirrel-cage structure consists of a stepped shaft 1, a first bearing 2, a second bearing 3, a first aluminum plate 4, a second aluminum plate 5, a third aluminum plate 6, a fourth aluminum plate 7, and a hub Spur gear 8, battery 9, control board 10, driver 11, stepper motor 12, reducer 13, flange 14, spur gear with hub 15, conductive slip ring 16, first end cover 17, second end cover 18, A battery charging head 19, a first connecting rod 20, a second connecting rod 21, and an outer cylinder 22, the first aluminum plate 4, the second aluminum plate 5, the third aluminum plate 6 and the fourth aluminum plate 7 together form a tray assembly; The above-mentioned stepping motor 12, speed reducer 13 and spur gear with hub 15 jointly constitute a driving device....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com