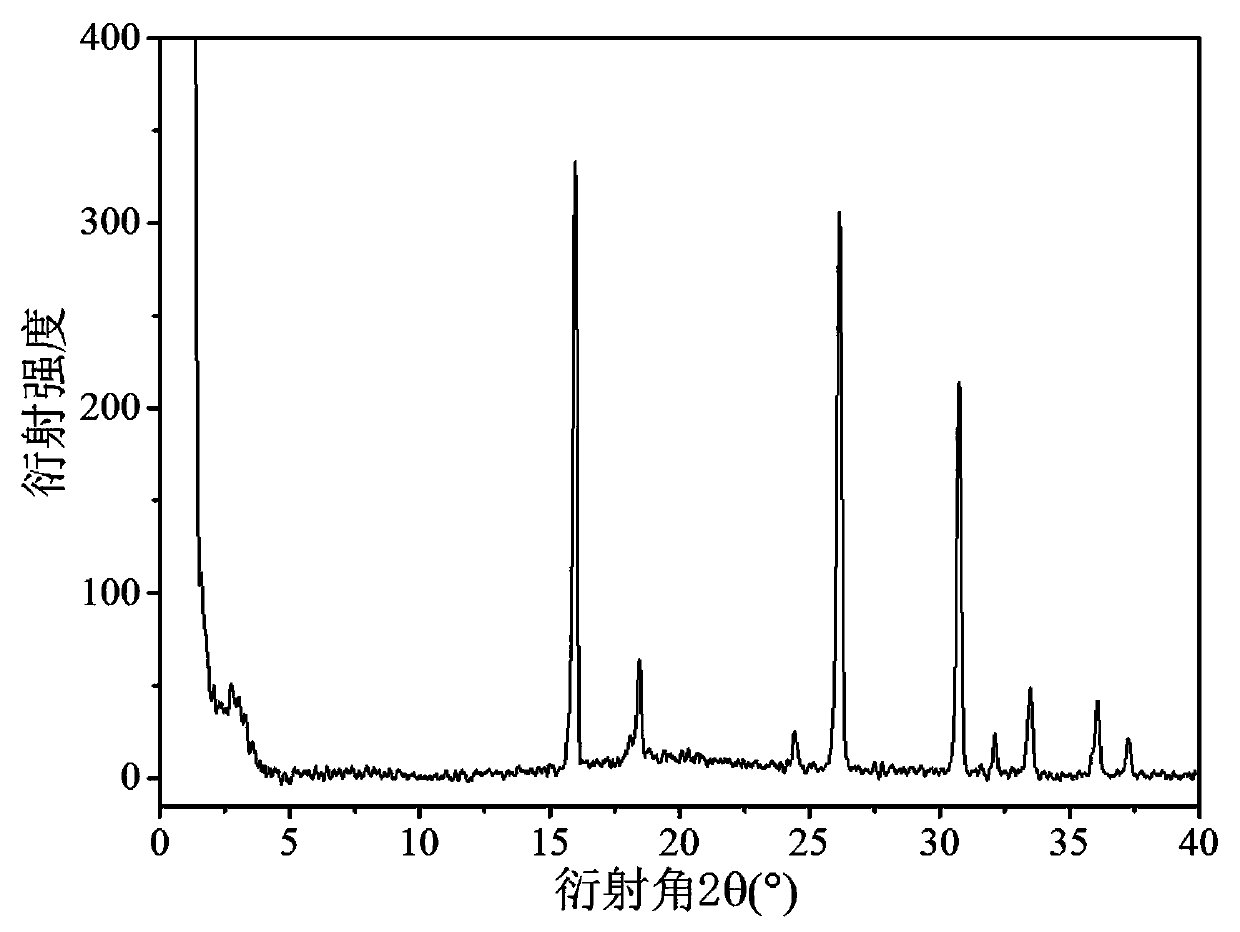

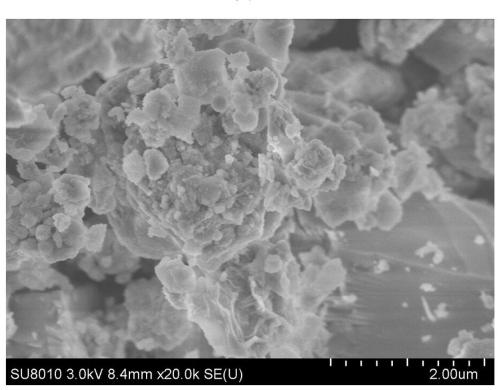

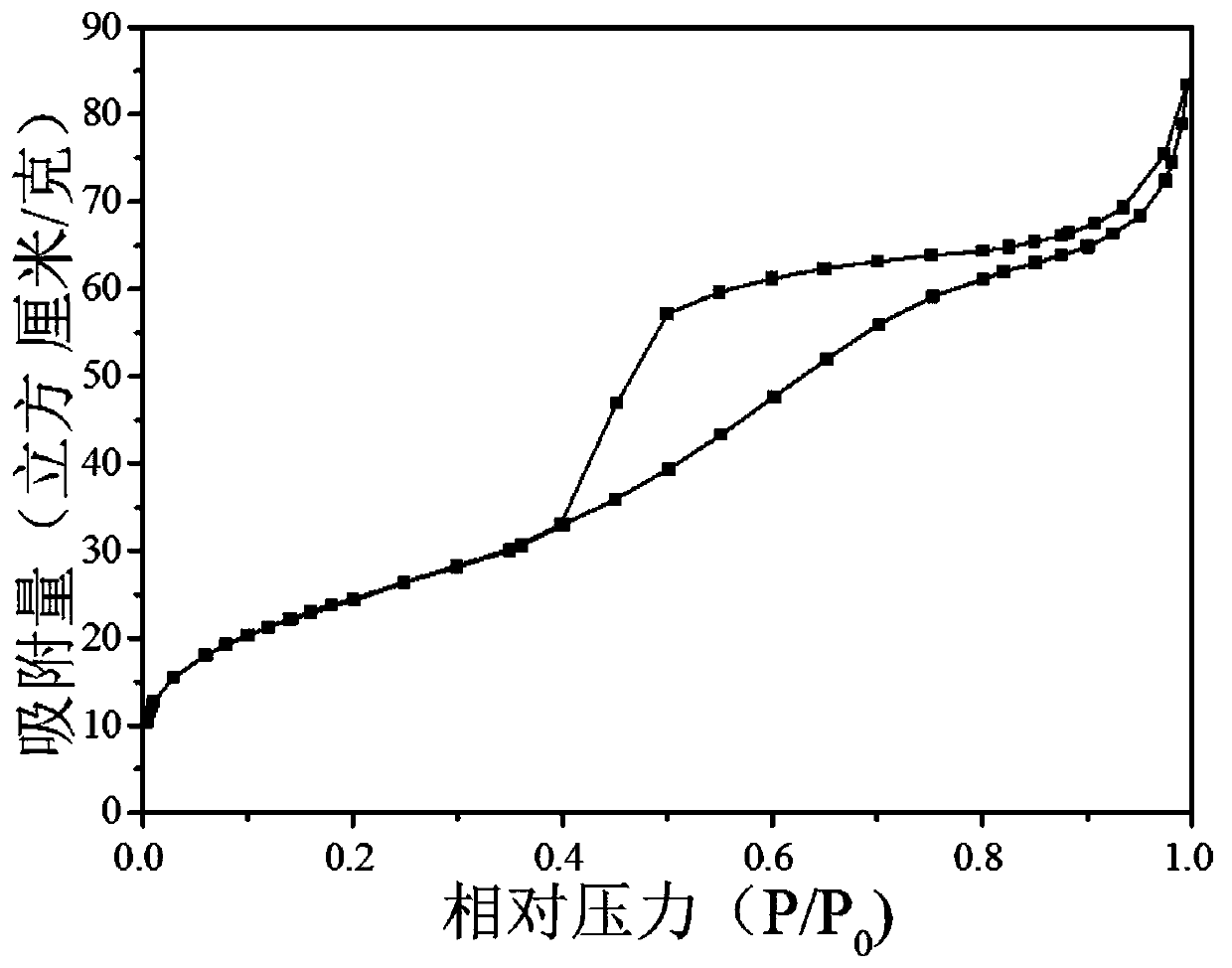

Preparation method of micro-mesoporous structure analcime

A mesoporous structure, analcite technology, applied in the direction of crystalline aluminosilicate zeolite, etc., can solve the problems of low utilization rate of raw materials, no synthesis rules, and high requirements for reaction conditions, achieve good market application and promotion value, and reasonable design. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0055] Specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

[0056] A kind of preparation method of multi-stage pore analcime, the chemical substance material used is: sodium metaaluminate, sodium hydroxide, deionized water, white carbon black, asymmetric gemini quaternary ammonium salt cationic surfactant, and its preparation dosage is as follows : in grams, milliliters, centimeters 3 as a unit of measurement

[0057] Sodium metaaluminate: NaAlO 2 0.630g±0.001g

[0058] Sodium Hydroxide: NaOH 0.480g ±0.001g

[0059] Silica: SiO 2 6.000g±0.001g

[0060] Unsymmetrical Gemini Quaternary Ammonium Salt Cationic Surfactant: C 33 h 72 N 2 Br 2 12.340g±0.001g

[0061] Deionized water: H 2 O 12.25mL±0.01mL

[0062] Argon: Ar 100000cm 3 ±100cm 3

[0063] C 33 h 72 N 2 Br 2 : Unsymmetrical Gemini quaternary ammonium salt cationic surfactant, its unique molecular structure formula is as follow...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com