Method for fermenting and producing curdlan

A fermentation liquid and fermentation culture technology, applied in the field of fermentation and production of curdlan gum, can solve the problems of low yield, long fermentation cycle, complicated process operation, etc., and achieve the effects of increased yield, simple operation and low price

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

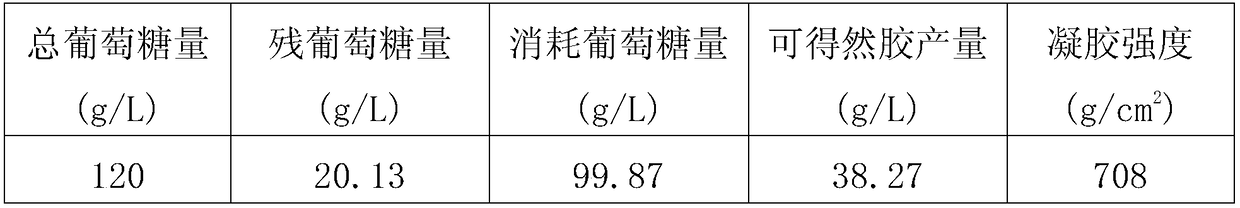

Embodiment 1

[0032] a. Seed culture: After the Agrobacterium strains are activated, they are transferred to the seed culture solution for cultivation. The cultivation temperature is 28-32°C, the pH value is adjusted to 6.5-7.5, the rotation speed is 180-200rpm, and the cultivation time is 28-28°C. 32h; wherein the components of the seed culture solution are: glucose 20g / L, corn steep liquor dry powder 10g / L, K 2 HPO 4 2g / L, MgSO 4 1g / L.

[0033] B. the grown Agrobacterium seed liquid is inserted in the 50L fermenter that 30L fermentation medium is housed with the inoculum size of 5% (v / v), and initial fermentation medium formula is: glucose 60g / L, dry powder of corn steep liquor 4g / L, (NH 4 ) 2 HPO 4 3g / L, KH 2 PO 4 2g / L, MgSO 4 1g / L, FeCl 3 0.01g / L, ZnCl 2 0.01g / L, polyether defoamer 0.04g / L, pH 6.8-7.0. The culture temperature is 30°C, the tank pressure is 0.05MPa, the ventilation ratio is 0.5vvm, and the stirring speed is 350r / min.

[0034] In the fermentation process...

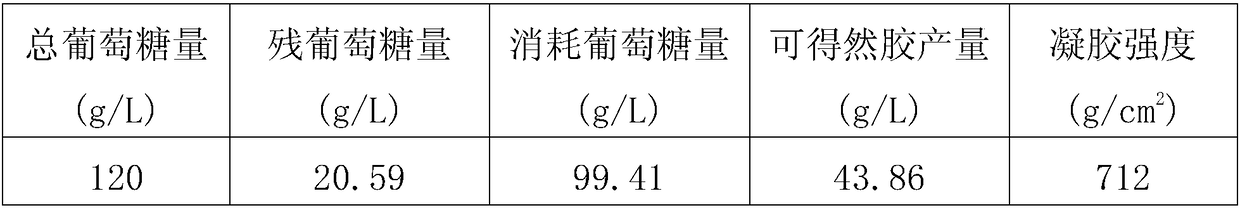

Embodiment 2

[0040] a. Seed culture: After the Agrobacterium strains are activated, they are transferred to the seed culture solution for cultivation. The cultivation temperature is 28-32°C, the pH value is adjusted to 6.5-7.5, the rotation speed is 180-200rpm, and the cultivation time is 28-28°C. 32h; wherein the components of the seed culture solution are: glucose 20g / L, corn steep liquor dry powder 10g / L, K 2 HPO 4 2g / L, MgSO 4 1g / L.

[0041]B. the grown Agrobacterium seed liquid is inserted in the 50L fermenter that 30L fermentation medium is housed with the inoculum size of 5% (v / v), and initial fermentation medium formula is: glucose 60g / L, dry powder of corn steep liquor 4g / L, (NH 4 ) 2 HPO 4 3g / L, KH 2 PO 4 2g / L, MgSO 4 1g / L, FeCl 3 0.01g / L, ZnCl 2 0.01g / L, polyether defoamer 0.04g / L, pH 6.8-7.0. The culture temperature is 30°C, the tank pressure is 0.05MPa, the ventilation ratio is 0.5vvm, and the stirring speed is 350r / min.

[0042] During the fermentation proc...

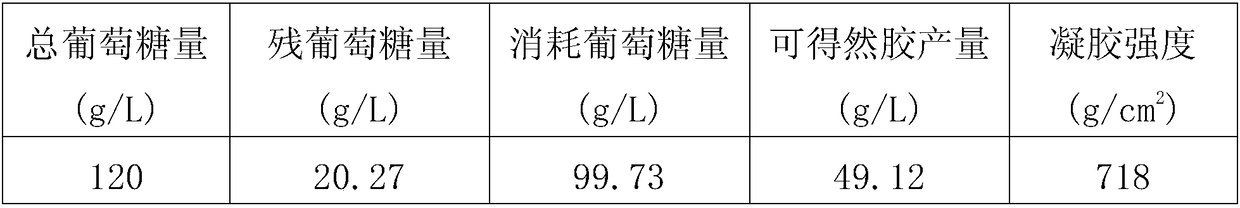

Embodiment 3

[0048] a. Seed culture: After the Agrobacterium strains are activated, they are transferred to the seed culture solution for cultivation. The cultivation temperature is 28-32°C, the pH value is adjusted to 6.5-7.5, the rotation speed is 180-200rpm, and the cultivation time is 28-28°C. 32h; wherein the components of the seed culture solution are: glucose 20g / L, corn steep liquor dry powder 10g / L, K 2 HPO 4 2g / L, MgSO 4 1g / L.

[0049] B. the grown Agrobacterium seed liquid is inserted in the 50L fermenter that 30L fermentation medium is housed with the inoculum size of 5% (v / v), and initial fermentation medium formula is: glucose 60g / L, dry powder of corn steep liquor 4g / L, (NH 4 ) 2 HPO 4 3g / L, KH 2 PO 4 2g / L, MgSO 4 1g / L, FeCl 3 0.01g / L, ZnCl 2 0.01g / L, polyether defoamer 0.04g / L, pH 6.8-7.0. The culture temperature is 30°C, the tank pressure is 0.05MPa, the ventilation ratio is 0.5vvm, and the stirring speed is 350r / min;

[0050] Feed KOH during the ferment...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com