High-flatness low-energy-consumption sector printing-dyeing drying drum

A low energy consumption, fan-shaped technology, applied in textiles and papermaking, textile processing machine accessories, removal of liquid/gas/steam, etc., can solve problems such as easy deformation, cylinder structural strength, poor rigidity, etc., to reduce temperature difference, reduce The effect of reducing energy consumption and reducing cylinder deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further described below according to the accompanying drawings and in conjunction with the embodiments.

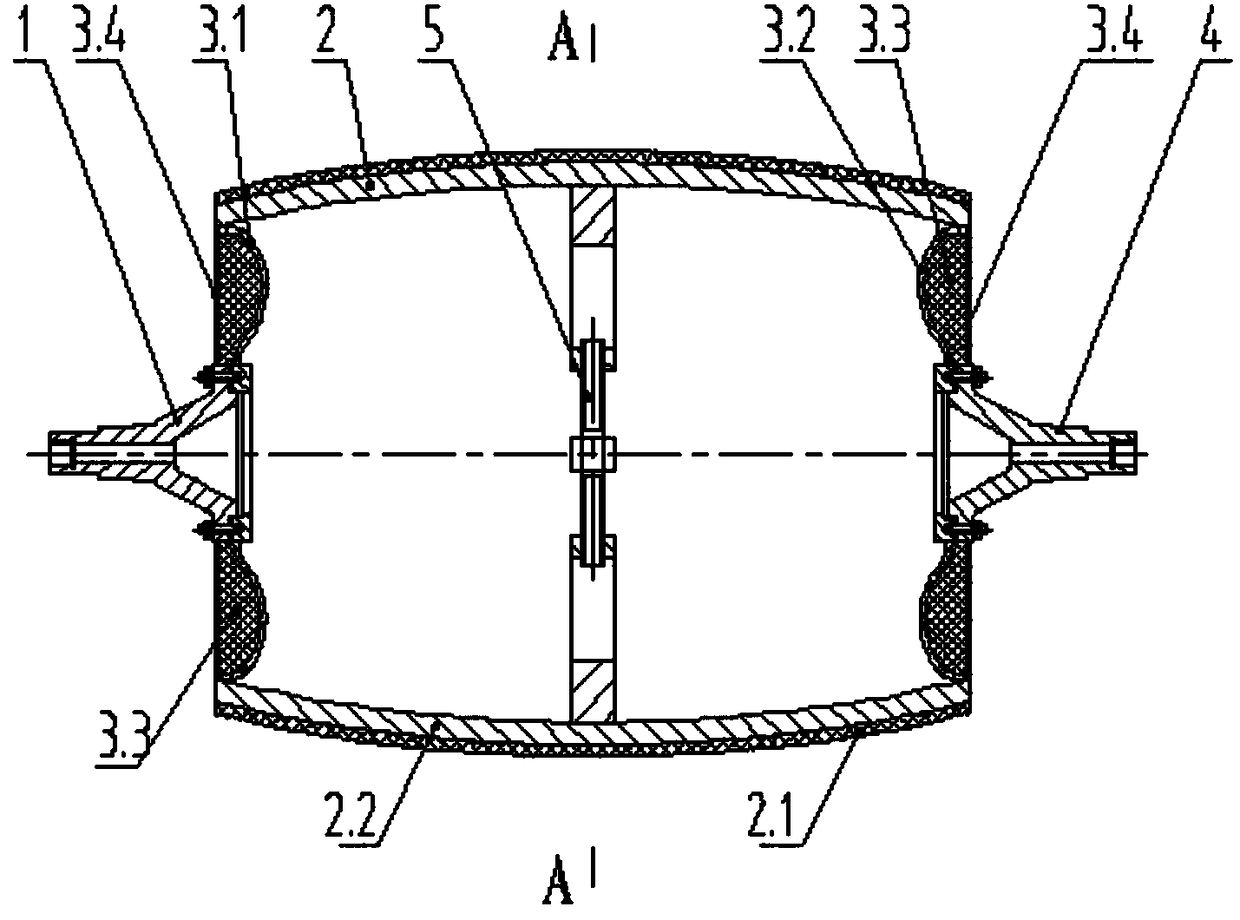

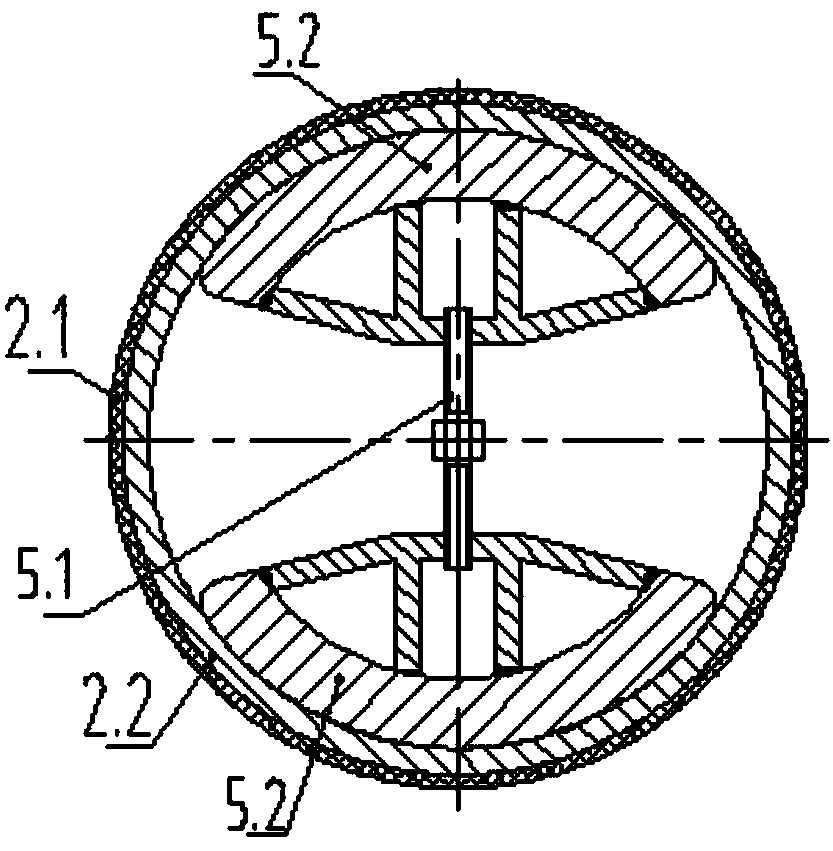

[0016] The fan-shaped printing and dyeing cylinder with high flatness and low energy consumption shown in the attached figure includes left shaft head 1, cylinder body 2, left head 3.1, right head 3.2, and right shaft head 4; The fan-shaped cylinder is fixedly connected between the left head 3.1 and the right head 3.2, the cylinder 2 is a composite cylinder, including the inner seamless cylinder 2.2, and the stainless steel outer layer coated on the outer wall of the seamless cylinder 2.2 2.1.

[0017] The left shaft head 1 is fixedly connected to the left side of the left head 3.1; the right shaft head 4 is fixedly connected to the right side of the right head 3.2; the left head 3.1 and the right head 3.2 are respectively provided with annular grooves; the left head 3.1, the right There are baffles 3.4 on the outside of the head 3.2; ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap