Double reheat thermodynamic system

A thermal system, secondary reheating technology, applied in steam engine installations, machines/engines, mechanical equipment, etc., can solve problems such as unsteady pressure, reduced work reliability, energy loss, etc., to improve energy conversion efficiency, improve Do functional ability, realize the effect of cascade utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

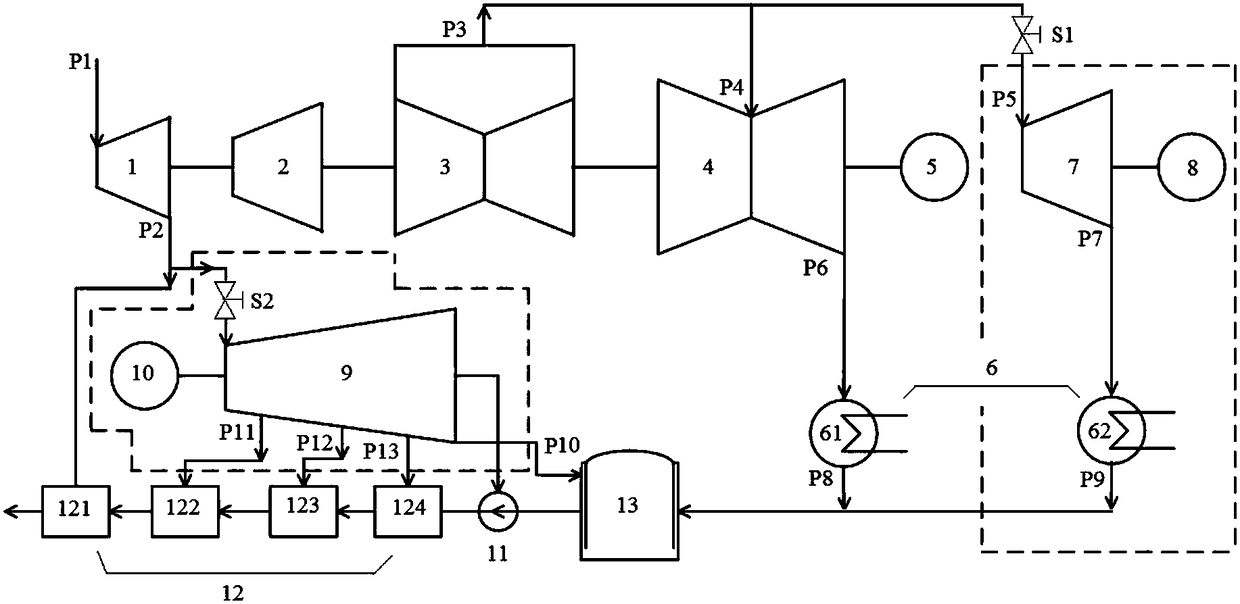

[0060] The layout of the thermal system of secondary reheating provided by the present invention is as attached figure 1 shown. The thermal system mainly includes a condenser 6 (preferably including a main condenser 61 and an auxiliary condenser 62), a bypass turbine 7, a hybrid drive turbine 9, and 4 high-pressure heaters (respectively No. 1 high-pressure heater 121 , No. 2 high-pressure heater 122, No. 3 high-pressure heater 123 and No. 4 high-pressure heater 124) and sequentially connected boilers and steam turbines (including sequentially connected ultra-high pressure cylinder 1, high-pressure cylinder 2, medium-pressure cylinder 3 and low-pressure cylinder 4) and the main generator 5, wherein the steam produced by the boiler enters the ultra-high pressure cylinder 1 through the steam inlet P1 of the ultra-high pressure cylinder 1, and the power generated by the low-pressure cylinder 4 is output to the main generator 5 for each power distribution equipment ( Such as steam...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com