Testing method for auxiliary cooling of thermal simulation test machine

A technology for auxiliary cooling and test methods, applied in heating or cooling equipment, chemical instruments and methods, laboratory utensils, etc., to achieve the effect of satisfying efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

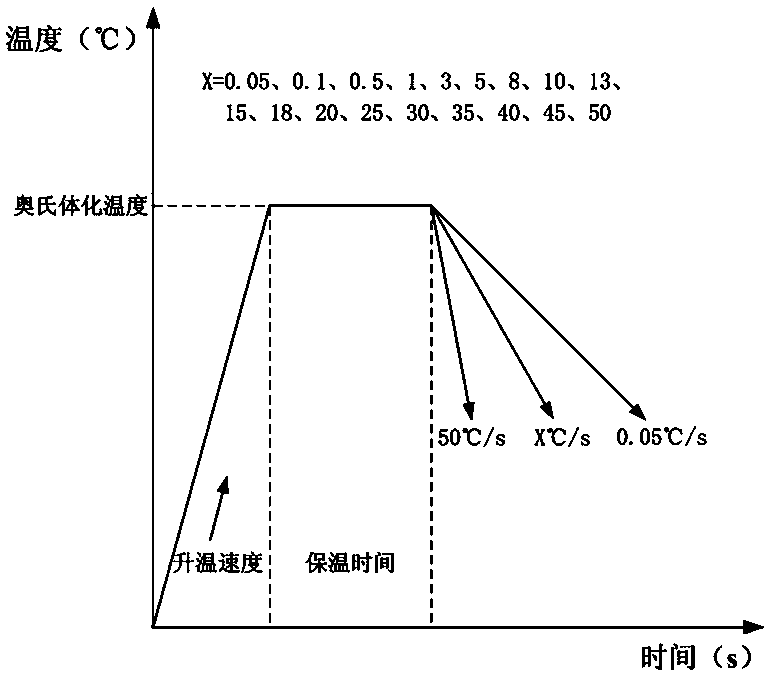

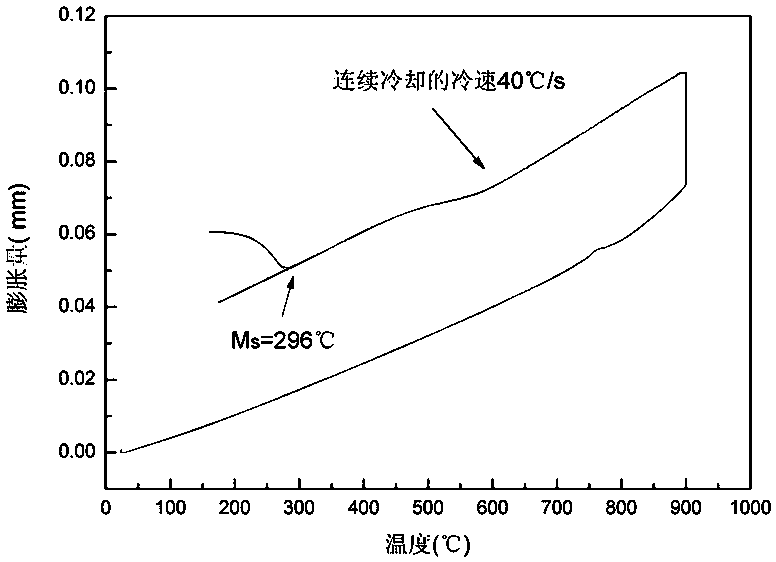

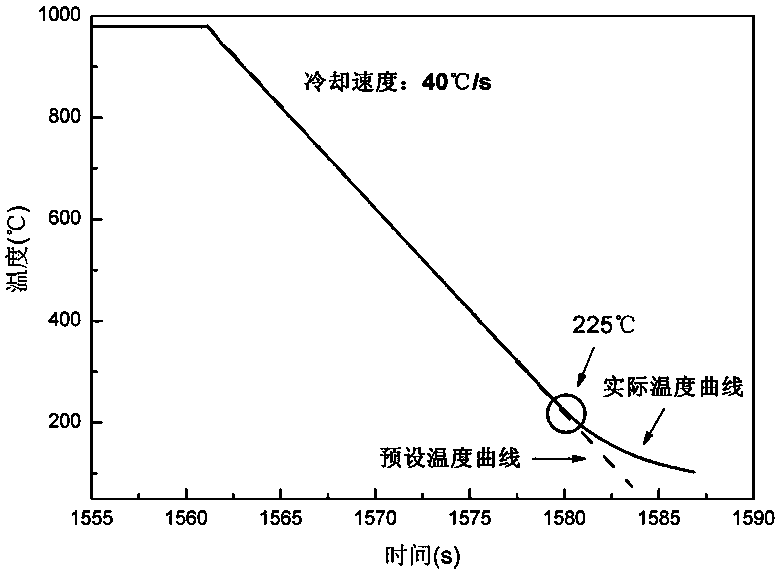

[0024] The implementation method proceeds as follows:

[0025] Process the axle steel EA1N into a dumbbell-shaped round bar with a total length of 75mm (the length of the left and right ends is 34.5mm, and the diameter is Φ10mm; the length of the uniform temperature zone is 6mm, and the diameter is Φ6mm);

[0026] Put two high-temperature ceramic tubes with an inner diameter of 0.3mm on the red and yellow thermocouples of the K-type thermocouple respectively to block the contact between the exposed part of the thermocouple wire and the surrounding metal, and then weld the K-type thermocouples separately by a spot welding machine In the center of the uniform temperature zone of the sample, it is arranged in a radial isothermal surface, and high-temperature cement is applied to the root of the solder joint to strengthen the solder joint.

[0027] Start the Gleeble3800 thermal simulation testing machine, put the dumbbell-shaped round bar sample welded with the thermocouple into t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The inside diameter of | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com