Corn threshing device

A corn threshing and corn technology, which is applied in threshing equipment, applications, agricultural machinery and tools, etc., can solve the problems of unclean threshing, time-consuming and labor-intensive, smashed and mixed corn cobs, etc., to reduce the moisture content of corn and have broad application prospects , to ensure the effect of completeness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

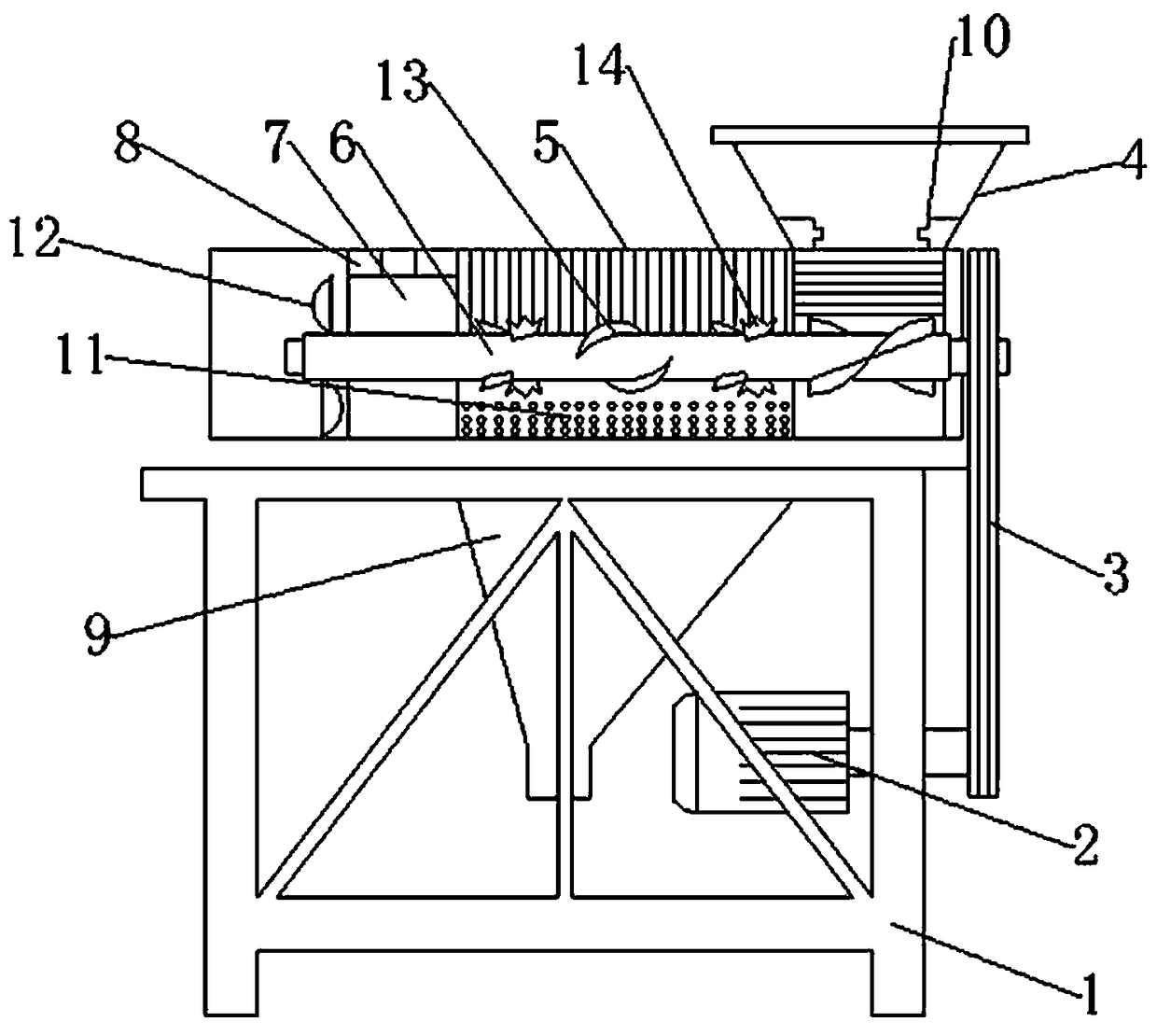

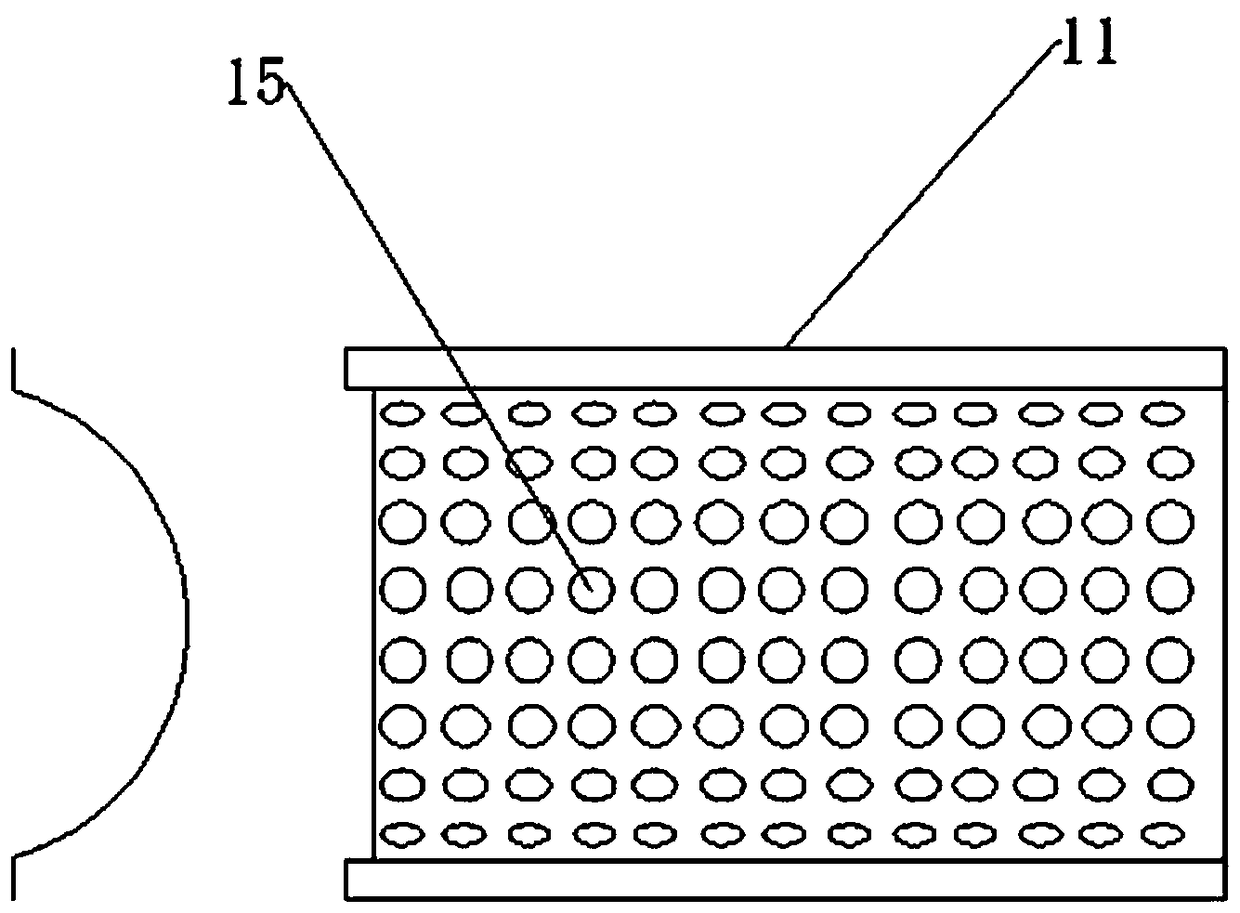

[0018] A corn threshing device, including a frame 1, a motor 2, a leather belt 3, a feed bin 4, a threshing bin 5, a toothed roller 6, a core discharge port 7, a core discharge dial 8, and a collection bin 9. It is: liquid nitrogen freeze dryers 10 are installed on both sides of the bottom of the feeding bin 4, the lower half of the threshing bin 5 is a curved plate sieve 11, and a negative pressure fan is installed on the end of the plate tooth drum 6 close to the core discharge port 7 12. There are spiral flat teeth 13 and spiral crown teeth 14 on the surface of the plate tooth drum 6, and sieve holes 15 are evenly distributed on the surface of the curved plate sieve 11. An application method of a corn threshing device is as follows: first, the motor 2 is started to rotate the toothed cylinder 6 through the belt 3, and the corn to be threshed is fed from the feeding bin 4, and firstly freeze-dried by the liquid nitrogen freeze dryer 10 After 10-12 seconds, the dried corn ent...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com