a soybean milk machine

A soymilk machine and machine head technology, applied in kitchen utensils, home utensils, beverage preparation devices, etc., can solve problems such as no good solution, foam overflow, etc., to improve the aesthetics, not easy to overflow, and reduce the difficulty of cleaning. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

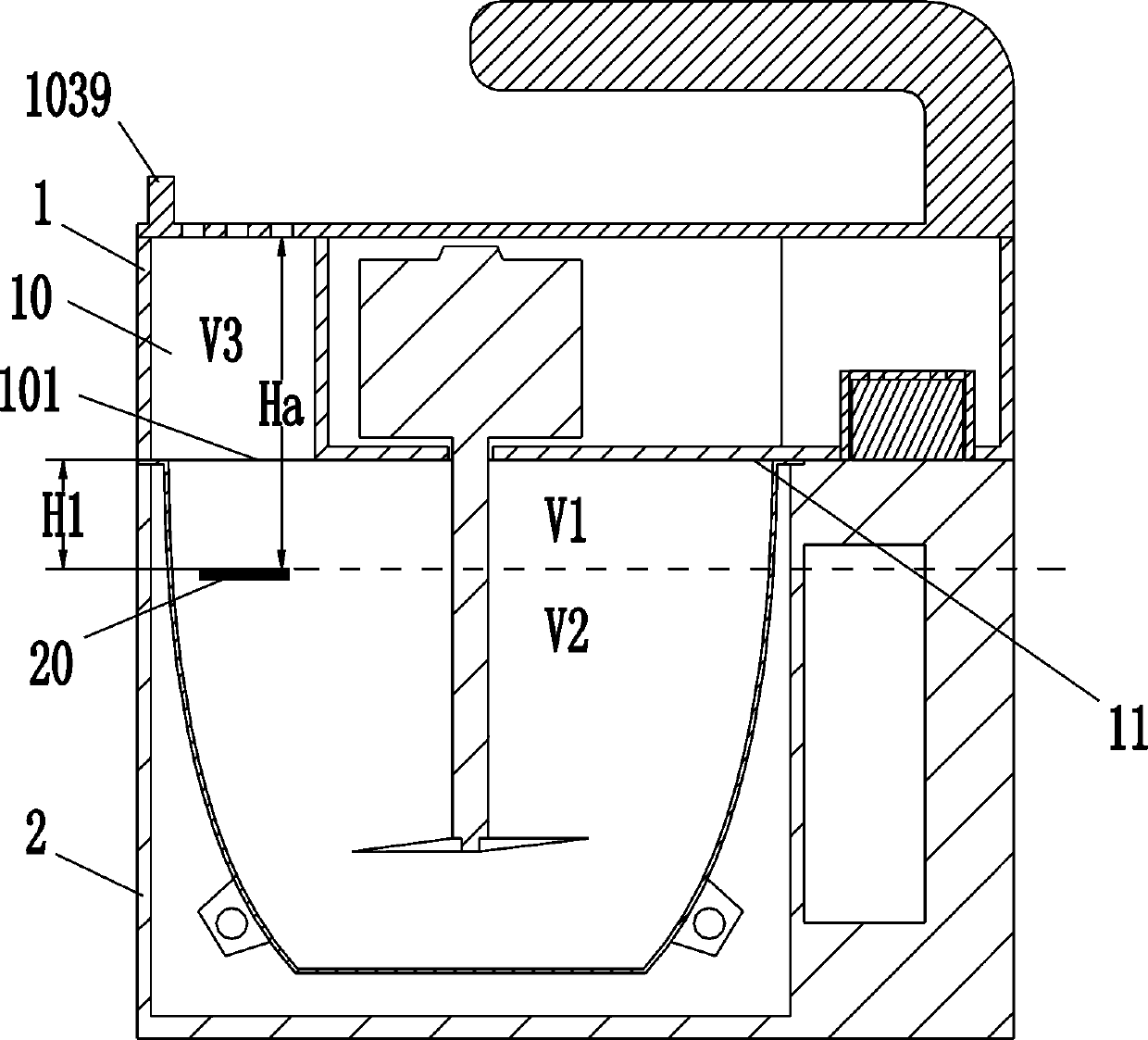

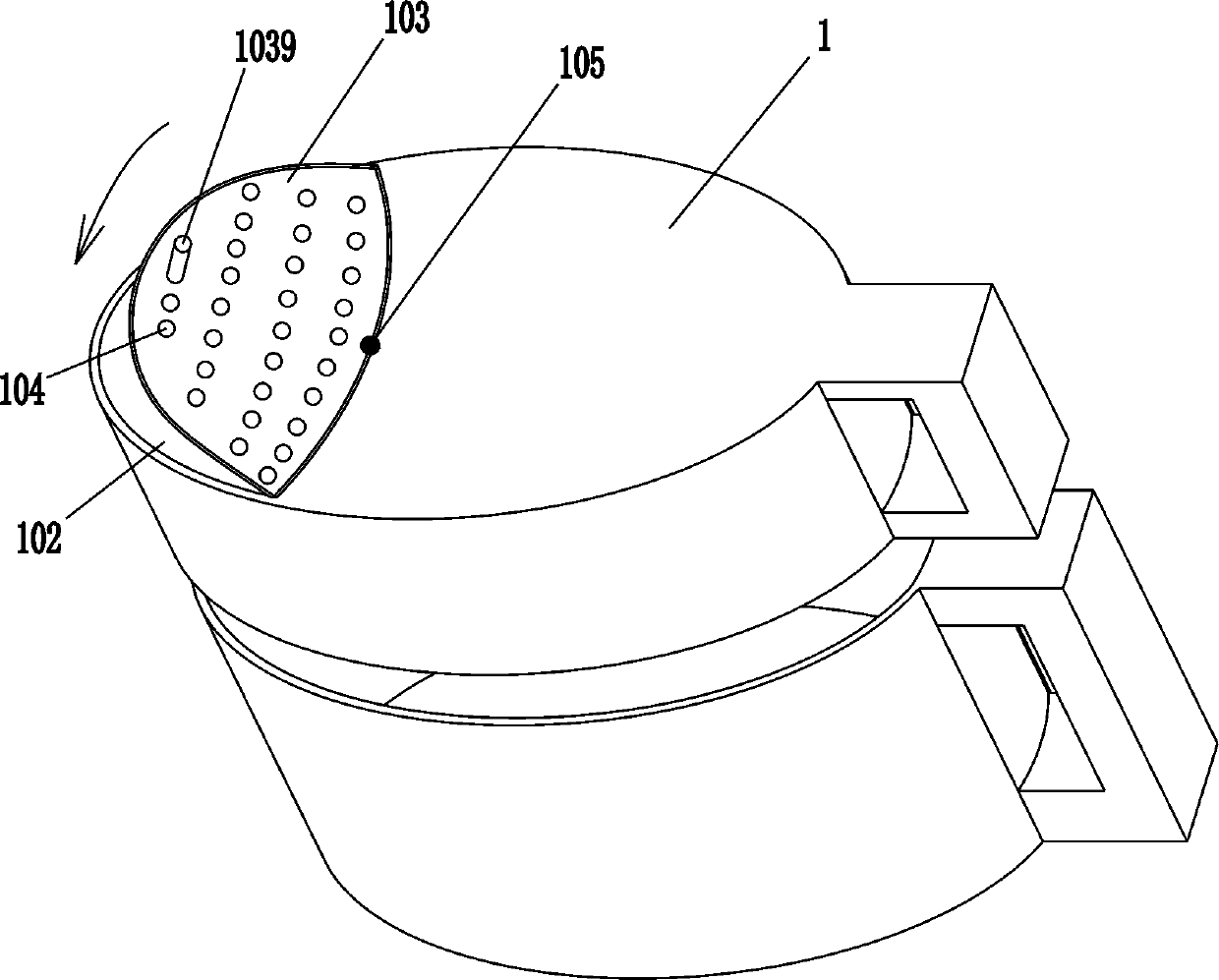

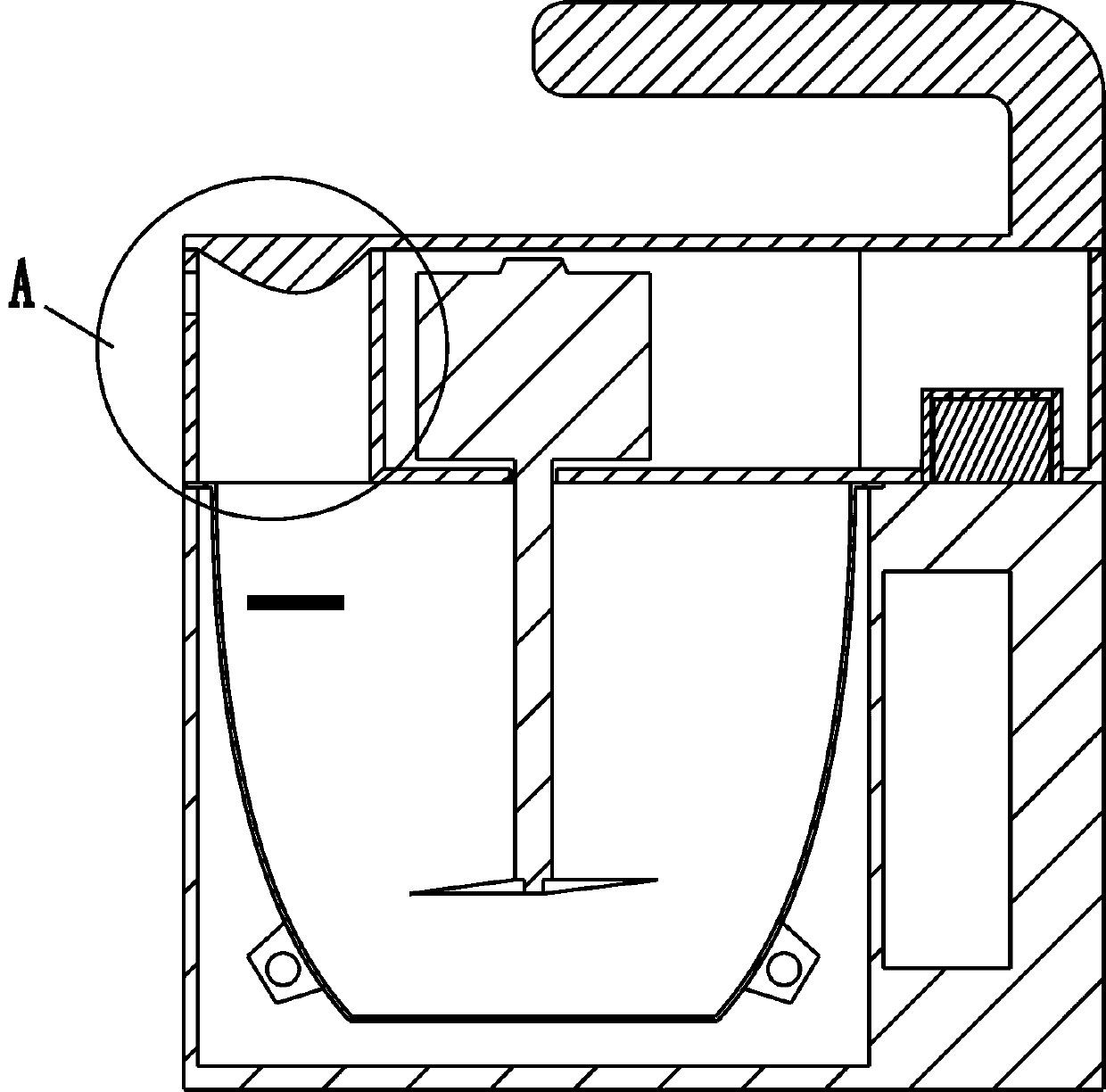

[0049] Such as figure 1 , figure 2 Shown is a schematic structural diagram of the first embodiment of the present invention. A soybean milk machine, comprising a machine head 1 and a cup body 2, the machine head is placed on the cup body, a water level marking line 20 is arranged on the side wall of the cup body, and the junction of the machine head 1 and the cup body 2 Seal fit, located above the water level marking line 20, the machine head 1 is provided with an anti-overflow chamber 10 with a bottom opening 101, the cup body 2 communicates with the anti-overflow chamber 10 through the bottom opening 101, and the slurry in the cup body It enters into the anti-overflow chamber 10 through the bottom opening 101 .

[0050] In this embodiment, the machine head 1 has a mounting surface 11 mounted on the rim of the cup, and the bottom opening 101 of the anti-overflow cavity is located on the plane where the mounting surface 11 is located. The holding surface 11 has the functio...

Embodiment 2

[0068] Such as image 3 , Figure 4 Shown is a schematic structural diagram of the second embodiment of the present invention. The difference between this embodiment and Embodiment 1 is that the cover plate in this embodiment is an anti-overflow cover 1030 for anti-overflow and defoaming of the slurry, and its bottom has a liquid collecting part protruding into the anti-overflow chamber 10, Wherein, the liquid collecting portion is a gradual protrusion 1031 formed from the edge of the spill-proof cover 1030 to the center of the spill-proof cover 1030, and the top opening edge of the spill-proof chamber 10 is provided with a support step 1021 supporting the spill-proof cover 1030, The anti-overflow cover 1030 is held on the support step 1021. In addition, a steam channel 106 communicating with the outside atmosphere of the machine head is also provided on the side wall of the anti-overflow chamber 10. The steam channel 106 can be used to evacuate part of the steam through the ...

Embodiment 3

[0072] Such as Figure 5 Shown is a schematic structural view of the third embodiment of the present invention. The difference between this embodiment and Embodiment 1 is that in this embodiment, the machine head includes a machine head body 12 and an anti-overflow assembly 13 detachably connected to the machine head body 12, and the anti-overflow chamber 10 is set On the anti-overflow assembly 13, and located above the anti-overflow assembly 13, an extension piece 14 connected to the top opening 102 of the anti-overflow chamber 10 is provided, and an expansion chamber 140 and an overfill-proof chamber are formed in the extension piece 14. 10 connectivity.

[0073] In this embodiment, the anti-overflow component with the anti-overflow cavity is detachably connected to the machine head body, which can facilitate cleaning of the anti-overflow cavity. Moreover, the expansion chamber is a supplement to the anti-overflow chamber, which can prevent the occurrence of pulp overflow ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com