A kind of preparation method and application of plga microspheres based on vortex oscillator

A technology of oscillators and microspheres, which is applied in the field of polymer microsphere preparation, can solve problems such as the limitation of emulsification degree and uniformity, the rotor flying off the bottom surface, and the loss of homogenization, etc., and achieves strong scalability, good safety, The effect of short emulsification time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

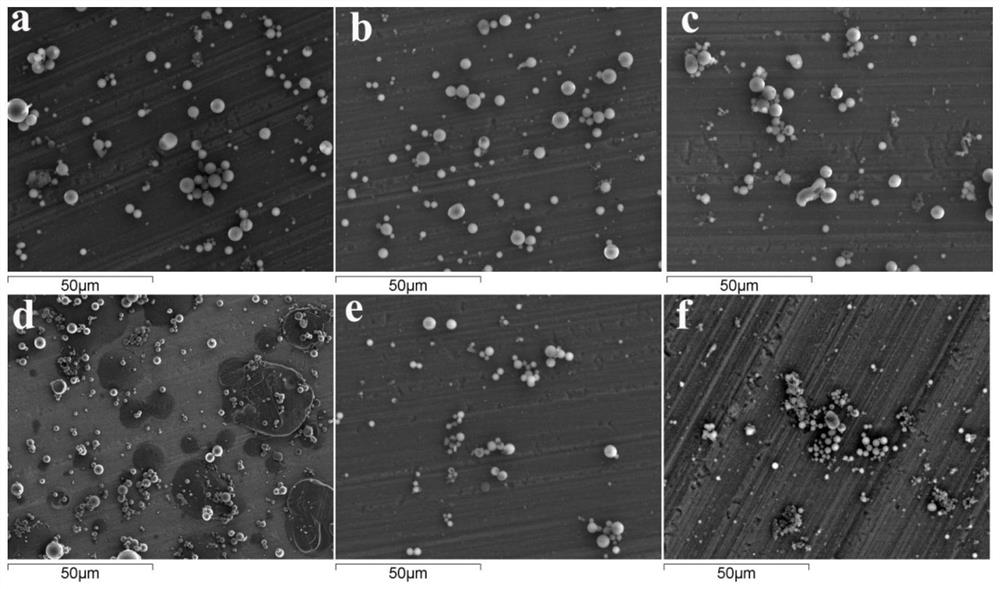

[0032] Embodiment 1: Preparation of PLGA microspheres of different particle sizes based on a uniform emulsification method of a vortex oscillator

[0033] (1) Preparation of the oil phase: Weigh 0.6g of PLGA, dissolve it in 10mL of dichloromethane, and prepare a 6% PLGA solution;

[0034] (2) Preparation of polyvinyl alcohol (PVA) aqueous solution: Weigh 2.5g of PVA solid, add it to 100mL of distilled water, heat and stir to fully dissolve, and prepare 2.5% PVA aqueous solution;

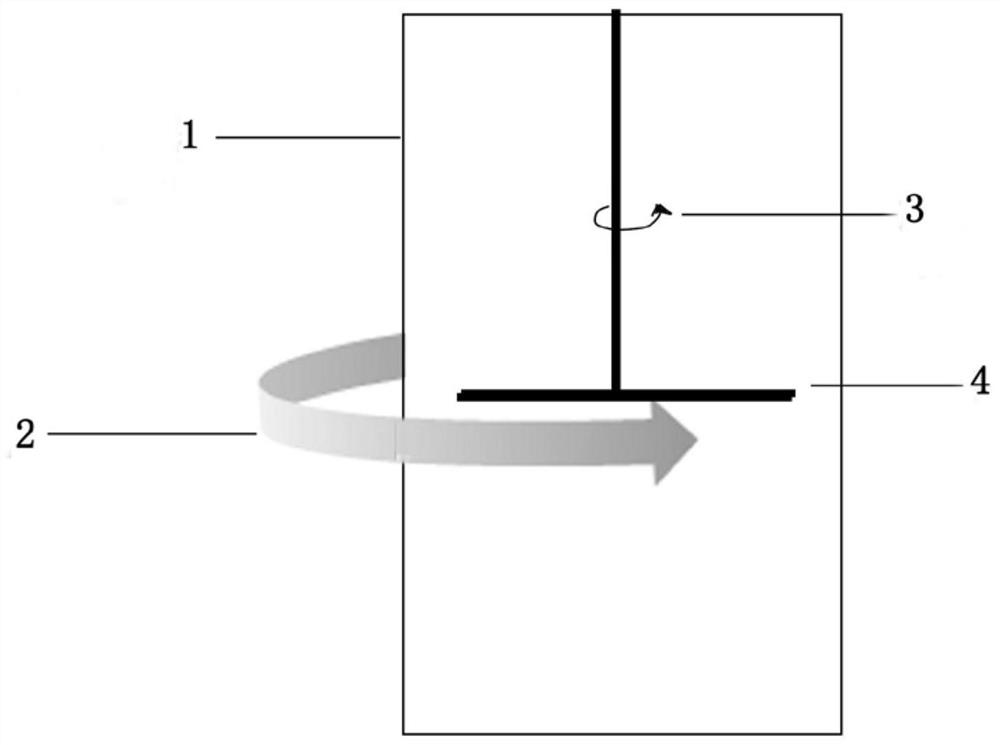

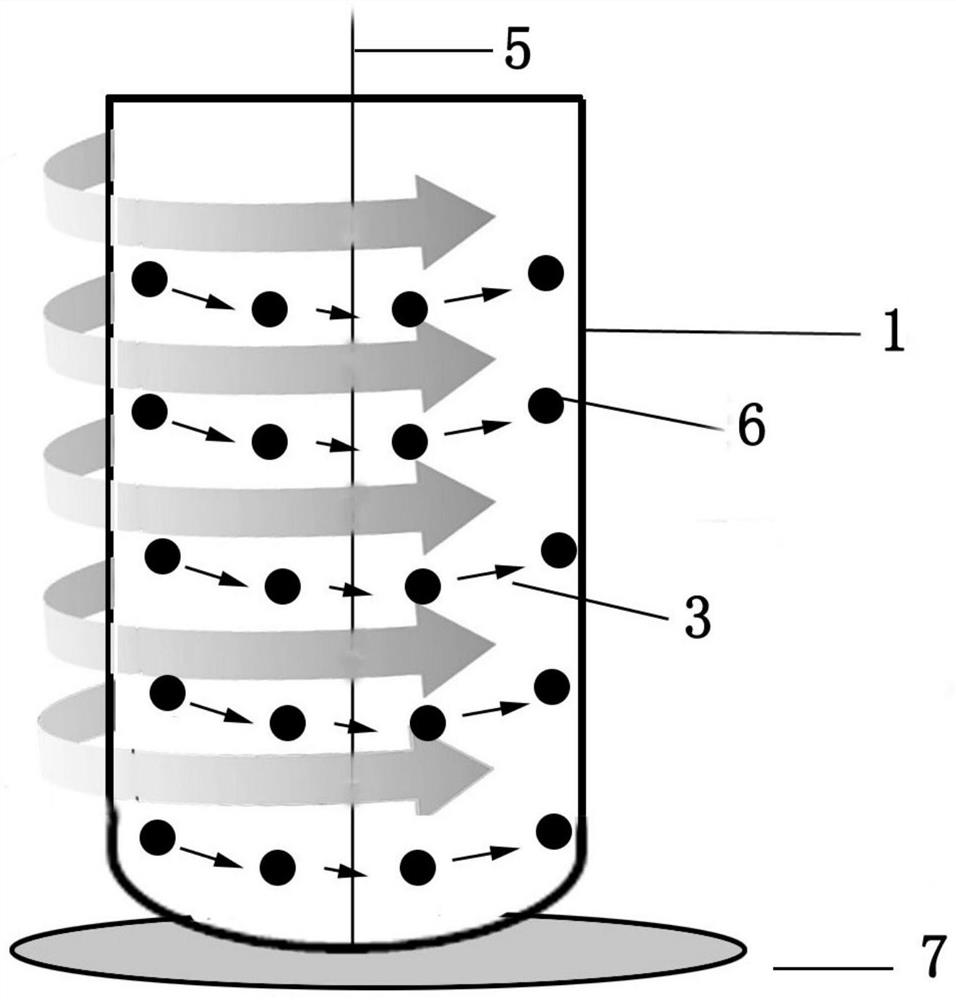

[0035] (3) Oscillating emulsification: In a 50mL centrifuge tube, add 10mL 2.5% PVA solution to each bottle, and disperse 1mL 6% PLGA oil phase solution in it, then add 7 glass beads with a diameter of 4-6mm, use the vortex The oscillator vibrates for 5min, 10min, and 20min at 1500 times / min, 3000 times / min, and 3000 rev / min oscillation frequencies respectively (the force of the emulsified solution based on the vortex oscillator is as follows: figure 2 shown);

[0036] (4) The volatilization of or...

Embodiment 2

[0040] Example 2: Preparation and enrichment of PLGA microspheres with uniform particle size of 2-3 μm

[0041] (1) Preparation of the oil phase: Weigh 0.6g of PLGA, dissolve it in 10mL of dichloromethane, and prepare a 6% PLGA solution;

[0042] (2) Preparation of PVA aqueous solution: Weigh 2.5g of PVA solid, add it into 100mL distilled water, heat and stir to fully dissolve, and prepare 2.5% PVA aqueous solution;

[0043] (3) Oscillating emulsification: In a 50mL centrifuge tube, add 10mL 2.5% PVA solution to each bottle, and disperse 1mL 6% PLGA oil phase solution in it, then add 8 glass beads with a diameter of 4-6mm, use the vortex The oscillator oscillates for 10 minutes at an oscillation frequency of 3000 times / min;

[0044] (4) The volatilization of organic solvent: place in fume hood and stir slowly to make dichloromethane organic solvent fully volatilize;

[0045] (5) Collection of PLGA microspheres: PLGA microspheres were collected by centrifugation at 2000 g for 2...

Embodiment 3

[0050] Example 3: Preparation of PLGA drug-loaded microspheres wrapped with rifampicin

[0051] In this example, rifampicin was used as the carrying object to prepare drug-loaded microspheres. The main purpose is to illustrate the application of the method of the present invention in the preparation of PLGA microspheres carrying oil-soluble drugs.

[0052] (1) Preparation of the oil phase: Weigh 0.6g PLGA and 0.05g rifampicin, dissolve them together in 10mL of dichloromethane, and prepare a solution containing 6% PLGA and 0.5% rifampicin;

[0053] (2) Preparation of PVA aqueous solution: Weigh 2.5g of PVA solid, add it into 100mL distilled water, heat and stir to fully dissolve, and prepare 2.5% PVA aqueous solution;

[0054] (3) Oscillating emulsification: In a 50mL centrifuge tube, add 10mL 2.5% PVA solution to each bottle, and disperse 1mL 6% PLGA oil phase solution in it, then add 8 glass beads with a diameter of 4-6mm, use the vortex The oscillator oscillates for 10 minu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com