Processing chip treatment system for numerical controlled milling machine for brittle metal material cutting process

A brittle metal, CNC milling machine technology, applied in metal processing equipment, metal processing machinery parts, milling machines, etc., can solve the problems of restricting the work efficiency of operators, increasing the difficulty of cleaning, and increasing the workload of cleaning, so as to reduce loss, The effect of reducing the amount of cleaning and reducing noise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

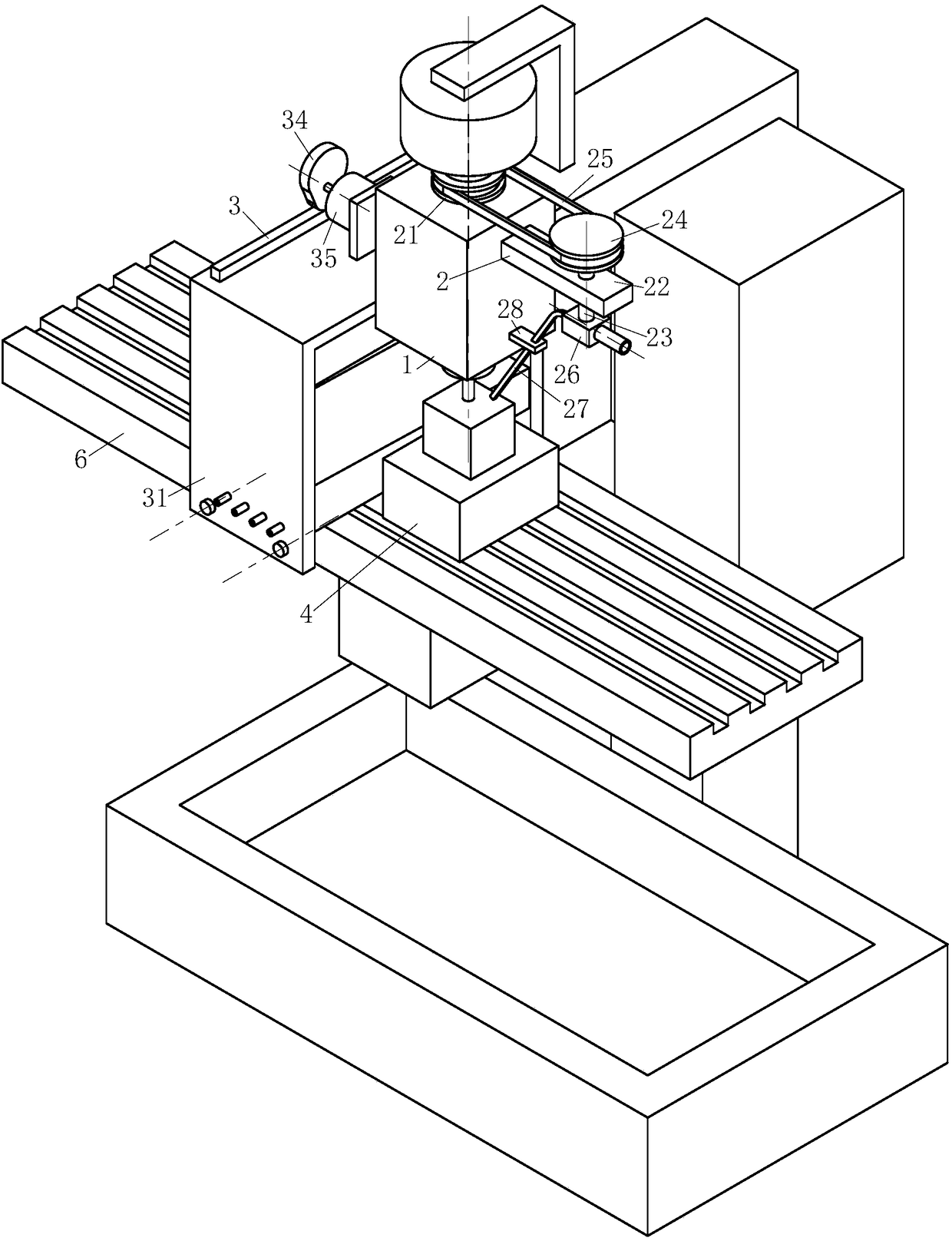

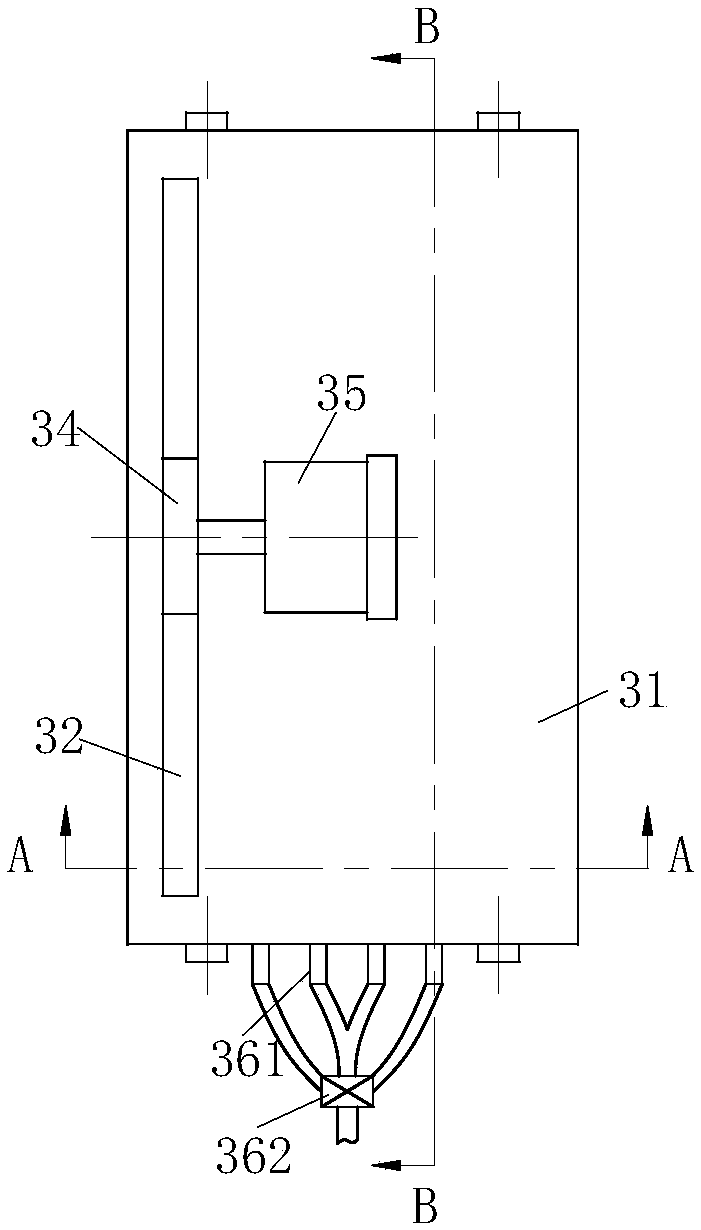

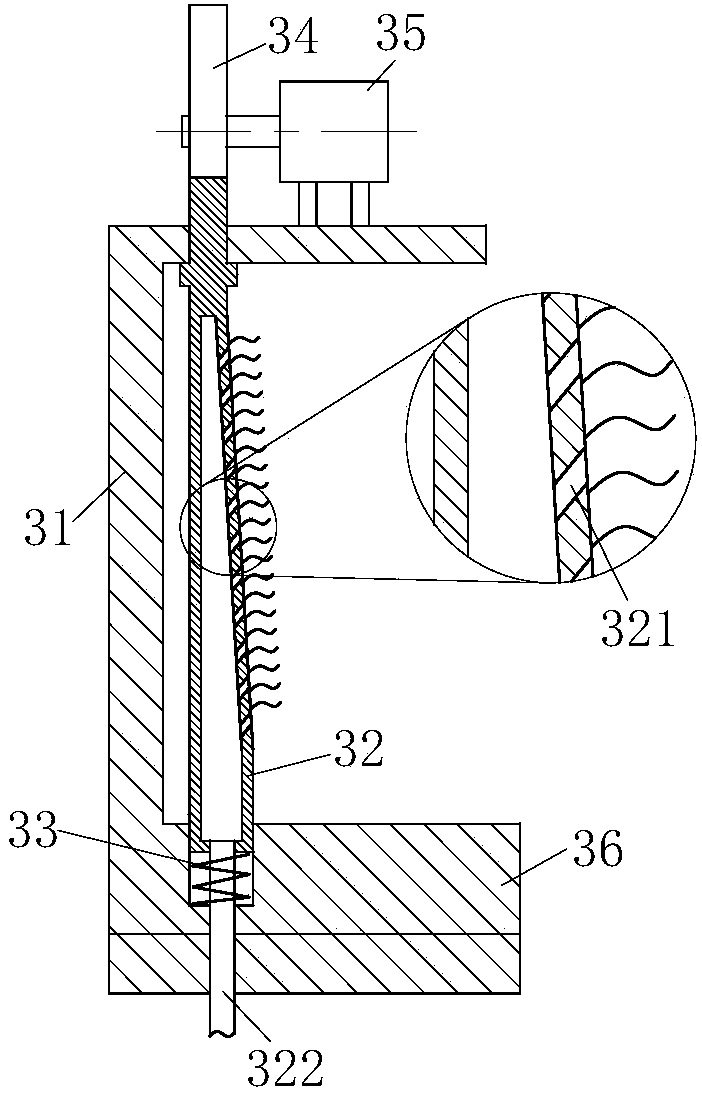

[0030] As an embodiment of the present invention, the injection module 2 includes a socket pulley 21, a mounting frame 22, a rotating shaft 23, a connecting pulley 24, a belt 25, an impeller box 26, a pipeline 27 and a support frame 28; The belt pulley 21 is fixedly installed on the milling machine spindle through bolts; the mounting frame 22 is fixedly mounted on one side of the milling machine headstock 1 through bolts; the rotating shaft 23 is mounted on the mounting frame 22 through bearing rotation; the upper end of the rotating shaft 23 is fixedly connected to The connecting pulley 24; the connecting pulley 24 and the sleeve pulley 21 are sheathed with a belt 25; the rotation of the main shaft can drive the connecting pulley 24 to rotate; the lower end of the rotating shaft 23 is fixedly connected to the impeller; the impeller is installed in the impeller box 26 for rotation; The impeller box 26 is fixedly installed on the lower end of the mounting frame 22; one side of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com