Sheathed open blank forging and shaping technique of titanium-aluminum alloy cast ingot

A blank forging and titanium-aluminum alloy technology, which is applied in the field of sheathed blank forging forging of titanium-aluminum alloy ingots, can solve problems such as mismatching, suppress deformation and cracking, improve deformation plasticity, and solve high-temperature deformation and forging The effect of blank mismatch

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

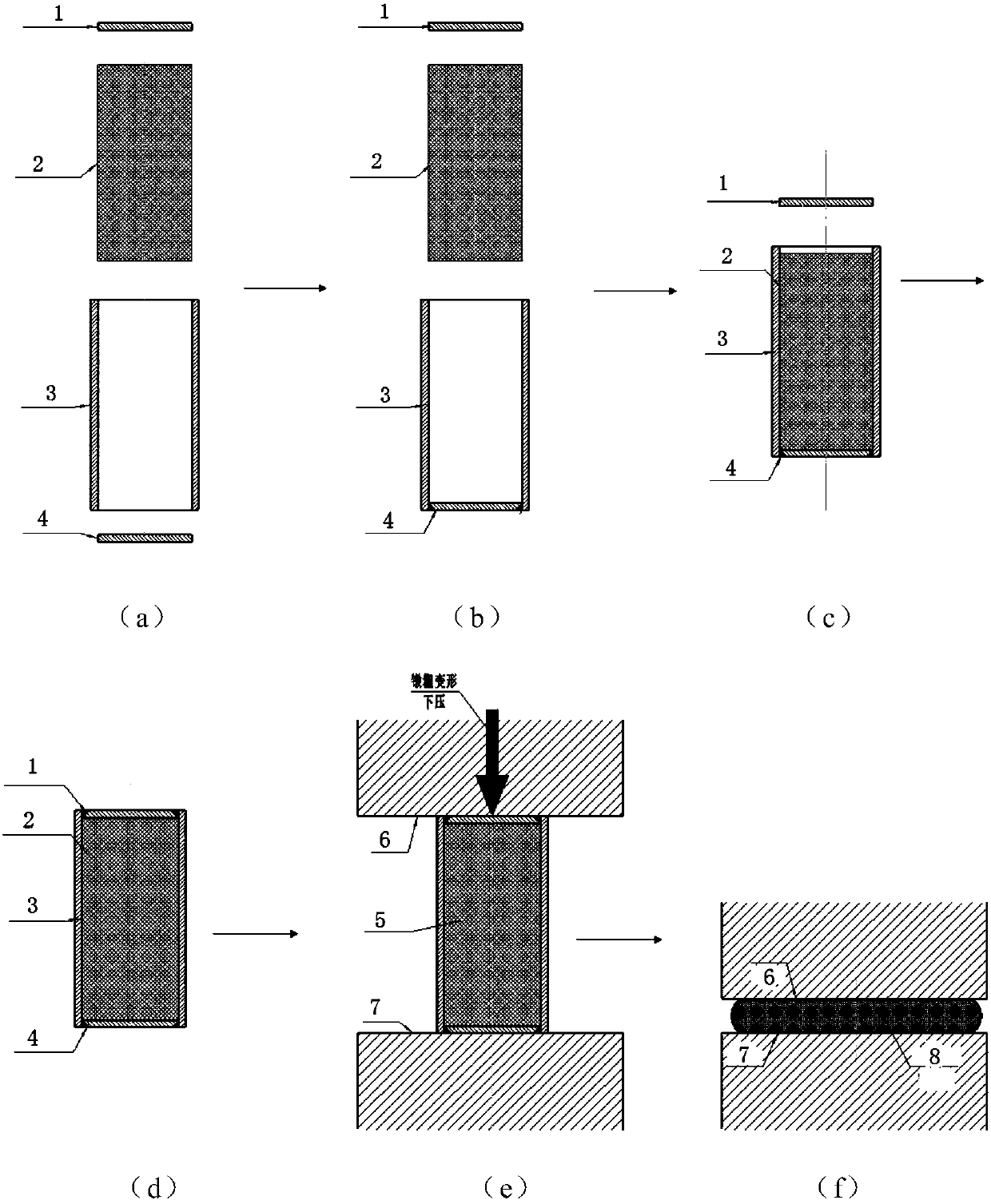

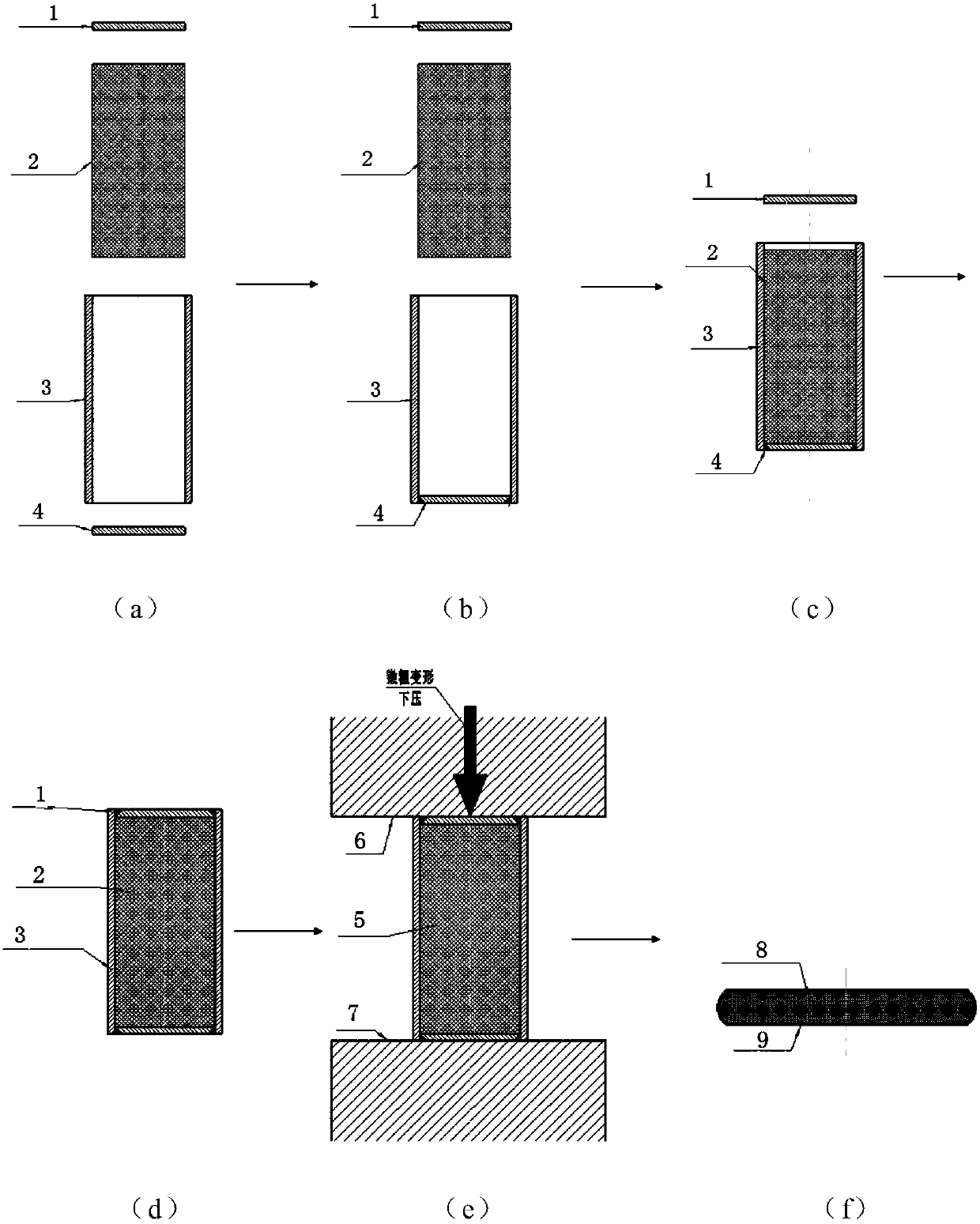

[0040] Example 1: Diameter titanium-aluminum alloy ingots are opened and forged, and the process diagram is shown in figure 2 . see figure 2(a), make material preparation first, see figure 2 (b), welding the lower cover, see figure 2 (c), the titanium-aluminum ingot is loaded into the sleeve body, see figure 2 (d), welding the upper cover, see figure 2 (e), heat forging is upsetting, see 2(f), complete forging, specifically including the following steps:

[0041] 1) Titanium-aluminum ingot preparation: unilaterally turning the outer surface of the titanium-aluminum ingot to remove 3mm of smelting skin, cutting off the riser of the ingot, cutting or turning the bottom surface of the ingot, and chamfering not less than R10, for There are no defects that have been removed by car cleaning. Careful grinding is required to remove them. The width / depth of the grinding must be greater than 8 / 1, and the transition should be smooth. The surface roughness of the ingot is 3.2...

Embodiment 2

[0052] Example 2: Diameter titanium-aluminum alloy ingots are opened and forged.

[0053] 1) Titanium-aluminum ingot preparation: unilaterally turn the outer surface of the titanium-aluminum ingot to remove 3mm of smelting skin, cut off the riser of the ingot, cut or remove the bottom surface of the ingot, and chamfer R12. In addition to clean defects, careful grinding is required to remove them. The width / depth of grinding must be greater than 8 / 1, and the transition should be smooth. The surface roughness of the ingot must not exceed 3.2 μm.

[0054] Specifications of titanium aluminum ingot: diameter is 160mm and height is 350mm.

[0055] 2) Preparation of sheath material: The sheath is composed of three parts: the upper cover plate 1, the lower cover plate 4, and the middle cylinder body 3, all of which are processed by turning TA15 titanium alloy forgings, and the surface roughness shall not be greater than 6.3 μm.

[0056] Upper and lower cover plate specifications:...

Embodiment 3

[0064] Example 3: Diameter titanium-aluminum alloy ingots are opened and forged.

[0065] 1) Titanium-aluminum ingot preparation: unilaterally turn the outer surface of the titanium-aluminum ingot to remove the smelting skin of 4 mm, cut off the riser of the ingot, cut off or remove the bottom surface of the ingot, and chamfer R12, for parts without Defects removed by the car must be carefully polished to remove them. The width / depth of the grinding must be greater than 8 / 1, and the transition should be smooth. The surface roughness of the ingot is 3.2μm.

[0066] Specifications of titanium aluminum ingot: diameter is 200mm and height is 420mm.

[0067] 2) Preparation of sheath material: The sheath is composed of three parts: the upper cover plate, the lower cover plate and the middle cylinder, all of which are processed by turning TC11 titanium alloy forgings with a surface roughness of 6.3 μm.

[0068] Upper and lower cover specifications: diameter It is 200mm and the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface roughness | aaaaa | aaaaa |

| surface roughness | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com