Preparation of impervious material for wall of leachate balance basin

A technology of a leachate regulating tank and an anti-seepage material is applied in the field of preparation of anti-seepage materials, which can solve the problems of decreased anti-seepage ability, high cost of raw materials, reduced anti-seepage performance, etc., and achieves enhanced anti-seepage performance, simple construction process, The effect of improved crack resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

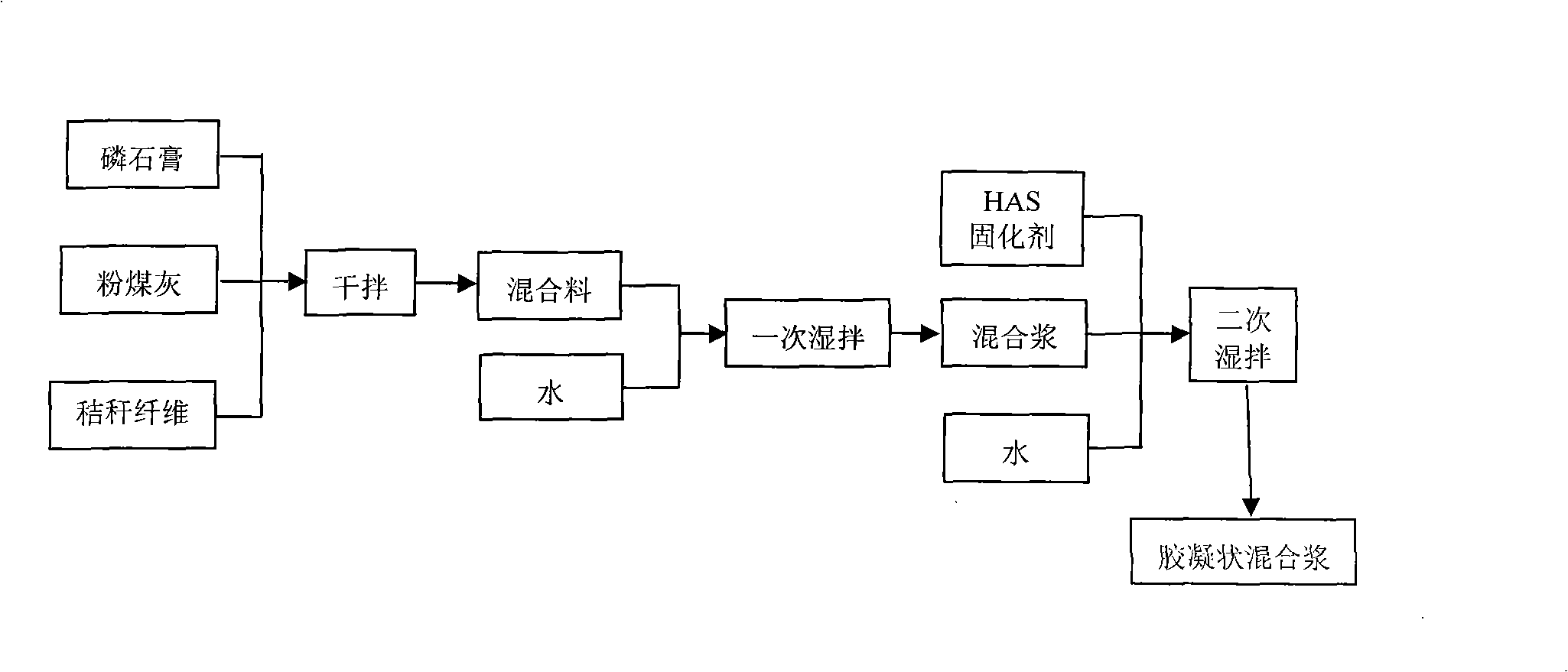

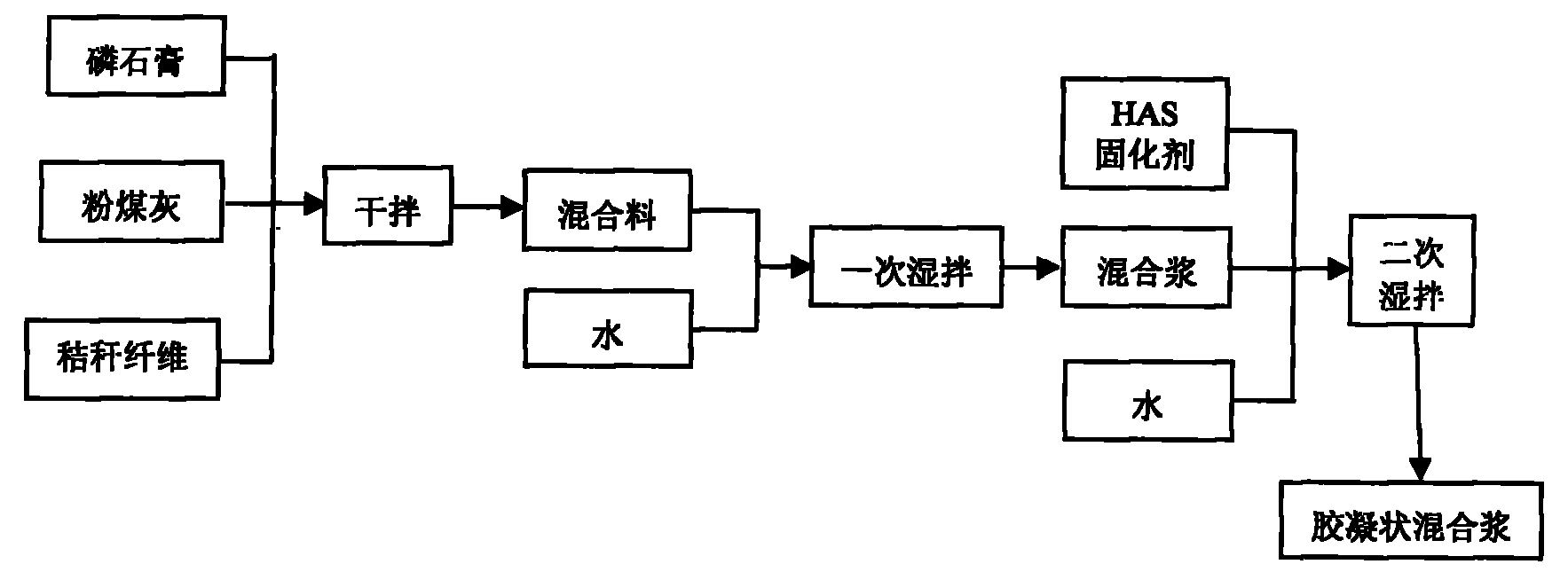

[0018] Below in conjunction with accompanying drawing, the preparation method of anti-seepage material of the present invention is described in further detail, and its preparation method process is as follows:

[0019] (1) Ingredients, weigh phosphogypsum and fly ash according to the mass ratio of 35% to 45% of phosphogypsum and 55% to 65% of fly ash, and then weigh the straw fiber according to the total mass of phosphogypsum and fly ash 0.08% to 0.1% weighed, of which, the optimum moisture content of fly ash is 26% to 30%, and the maximum dry density is 1.15 to 1.3g / cm 3 , the maximum particle size shall not exceed 5mm, and the loss on ignition shall be less than 3%; the length of the straw fiber shall be 6-19mm.

[0020] (2) Dry mixing, dry mixing the weighed phosphogypsum, fly ash and straw fiber to form a mixture.

[0021] (3) One-time wet mixing, add water to the dry-mixed uniform mixture according to 19%-22% of the total mass of phosphogypsum and fly ash, and use a mixe...

specific Embodiment 1

[0024] (1) Ingredients, weigh 350kg of phosphogypsum, 650kg of fly ash and 0.8kg of straw fiber, wherein the particle size of fly ash is ≤5mm; the length of straw fiber is 6mm.

[0025] (2) Dry mixing, dry mixing the weighed phosphogypsum, fly ash and straw fiber to form a mixture.

[0026] (3) One-time wet mixing, add 19kg of water to the uniformly stirred mixture, and stir with a mixer with a rotation speed of 17r / min for 2min to form a mixed slurry.

[0027] (4) Dosing, add 55kg of HAS curing agent and 5kg of water to the mixed slurry formed after stirring.

[0028] (5) Secondary wet mixing, the mixed slurry added with HAS curing agent and water is stirred by a mixer with a rotating speed of 17r / min, and the stirring time is 3min to form a gelled mixed slurry (ie finished product).

specific Embodiment 2

[0029] (1) Ingredients: weigh 450kg of phosphogypsum, 550kg of fly ash and 1kg of straw fiber, wherein the particle size of the fly ash is ≤5mm; the length of the straw fiber is 19mm.

[0030] (2) Dry mixing, dry mixing the weighed phosphogypsum, fly ash and straw fiber to form a mixture.

[0031] (3) One-time wet mixing, add 22kg of water to the well-stirred mixture, and stir with a mixer with a rotation speed of 17r / min for 2min to form a mixed slurry.

[0032] (4) Dosing, add 110kg of HAS curing agent and 8kg of water to the mixed slurry formed after stirring.

[0033] (5) Secondary wet mixing, the mixed slurry added with HAS curing agent and water is stirred by a mixer with a rotating speed of 17r / min, and the stirring time is 3min to form a gelled mixed slurry (ie finished product).

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com