Temperature-controllable near-isothermal plastic processing technology for high-entropy alloys

A high-entropy alloy and plastic processing technology, applied in the field of warm plastic processing, can solve the problems of easy cracking, high temperature dependence of deformation, high-entropy alloy lattice distortion, etc., to refine grains, improve mechanical properties and cost. low effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] Example 1: Al 1.5 CoCrFeNi as-cast high-entropy alloy processing modification, it combines plasticity modification of the present invention The specific embodiment is as follows:

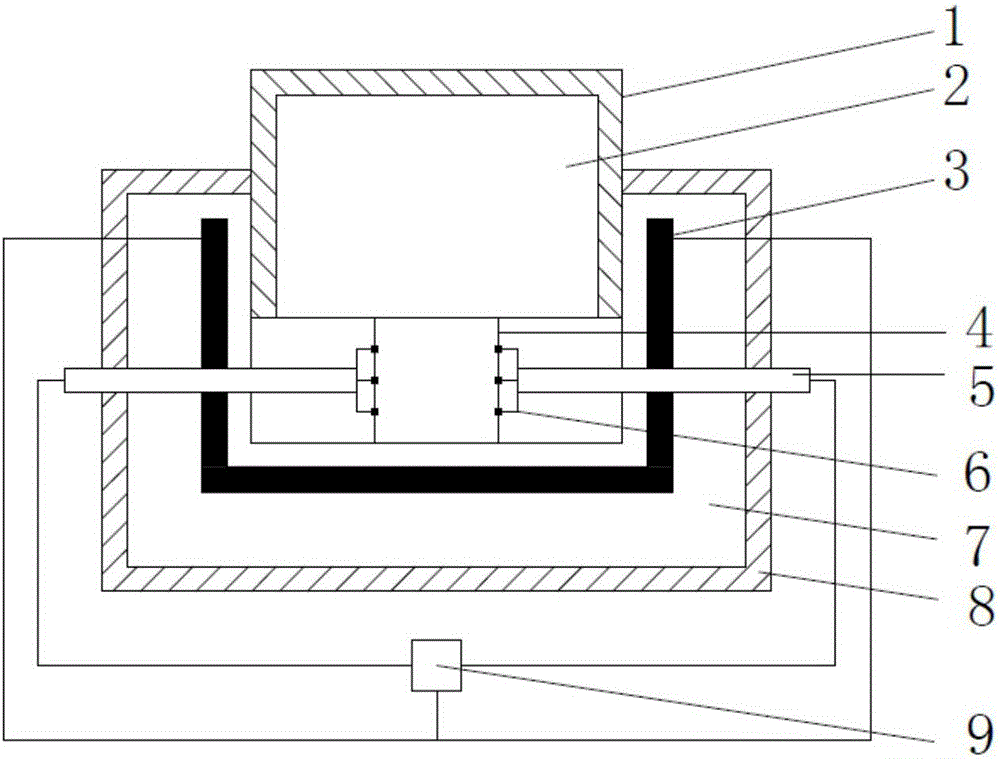

[0026] 1. Al through a heating furnace 1.5 The CoCrFeNi ingot was heated to 1150°C and kept for 30 minutes to homogenize the structure. Al is removed from the furnace 1.5 The CoCrFeNi cast ingot is placed between the lower die 6 and the upper punch 2 with heating and heat preservation while suppressing convective radiation heat dissipation by manipulators or clamps, and the ingot is clamped by the left and right clamping mechanisms 5, while relying on The sensor 6 on the clamping mechanism collects the temperature gradient distribution of the ingot along the height direction in real time.

[0027] 2. Combining the temperature gradient distribution collected by the clamping mechanism 5 and the Al 1.5 The crystal structure of CoCrFeNi high-entropy alloy (BCC) and the crystal lattice distort...

Embodiment 2

[0033] Example 2: CoCrFeNiTi 0.5 As-cast high-entropy alloy processing modification, it is combined with the plastic modification of the present invention The specific embodiment is as follows:

[0034] 1. Put CoCrFeNiTi into 0.5 The ingot was heated to 1100°C and kept for 30 minutes to homogenize the structure. Take out CoCrFeNiTi from the furnace 0.5 The as-cast ingot is placed between the lower die 6 and the upper punch 2 with heating and heat preservation and can suppress convection radiation heat dissipation through a manipulator or clamps, and the ingot is clamped by the left and right clamping mechanisms 5, while relying on the clamp The sensor 6 on the holding mechanism collects the temperature gradient distribution of the ingot along the height direction in real time.

[0035] 2. Combining the temperature gradient distribution collected by the clamping mechanism 5 and the CoCrFeNiTi 0.5 The high-entropy alloy (FCC) crystal structure and the lattice distortion of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com