Aluminum-plated and gold-stamped nonwoven fabric

A non-woven, aluminum bronzing technology, applied in the direction of non-woven fabrics, textile decoration, textiles and papermaking, etc., can solve the problem of difficult to meet the effect, achieve not easy to discolor and fall off, high elongation, good high temperature resistance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

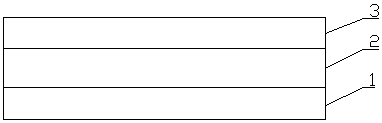

Image

Examples

Embodiment 1

[0044] Mix 90 parts of polypropylene, 6 parts of silicon dioxide, and 4 parts of carbon black, and put them into the extruder. After melting and extruding, the non-woven fabric matrix is formed by cooling into a net. The diameter of the fiber filament is 0.012mm, and the specification is 25dtex / 1f-36f, overall thickness 0.1mm, density 65g / m 2 ; Then coat the aluminum film layer on the surface of the non-woven fabric substrate, and coat the UV adhesive on the surface of the aluminum film layer; then lay the non-woven fabric substrate with the aluminum film layer on the hot stamping workbench with air suction holes on the surface The surface of the aluminum film layer is facing upwards; then the anodized aluminum foil tape is pressed to the aluminum film layer in the non-woven fabric matrix by the pressing roller, and the surface of the anodized aluminum foil tape is contacted with the aluminum film layer by the hot stamping head, and the hot stamping workbench In a vacuum st...

Embodiment 2

[0046] Mix 80 parts of polypropylene, 10 parts of silicon dioxide, and 10 parts of carbon black, and put them into the extruder. After melting and extruding, the non-woven fabric matrix is formed by cooling into a net. The diameter of the fiber filament is 0.012mm, and the specification is 25dtex / 1f-36f, overall thickness 0.1mm, density 65g / m 2 ; Then coat the aluminum film layer on the surface of the non-woven fabric substrate, and coat the UV adhesive on the surface of the aluminum film layer; then lay the non-woven fabric substrate with the aluminum film layer on the hot stamping workbench with air suction holes on the surface The surface of the aluminum film layer is facing upwards; then the anodized aluminum foil tape is pressed to the aluminum film layer in the non-woven fabric matrix by the pressing roller, and the surface of the anodized aluminum foil tape is contacted with the aluminum film layer by the hot stamping head, and the hot stamping workbench In a vacuum ...

Embodiment 3

[0048] Mix 80 parts of polypropylene, 10 parts of silicon dioxide, and 10 parts of carbon black, and put them into the extruder. After melting and extruding, the non-woven fabric matrix is formed by cooling into a net. The diameter of the fiber filament is 0.012mm, and the specification is 25dtex / 1f-36f, overall thickness 0.1mm, density 65g / m 2 ; Then coat the aluminum film layer on the surface of the non-woven fabric substrate, and coat the UV adhesive on the surface of the aluminum film layer; then lay the non-woven fabric substrate with the aluminum film layer on the hot stamping workbench with air suction holes on the surface The surface of the aluminum film layer is facing upwards; then the anodized aluminum foil tape is pressed to the aluminum film layer in the non-woven fabric matrix by the pressing roller, and the surface of the anodized aluminum foil tape is contacted with the aluminum film layer by the hot stamping head, and the hot stamping workbench In a vacuum ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com