Water glass solution heat recycling device used for white carbon black production

A technology of heat recovery device and production water, which is applied in the direction of filtration and separation, alkali metal silicate, silicate, etc., which can solve the problems of large heat loss and no recovery, etc., to prolong the life of filter plates, increase production, and economic benefits significant effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

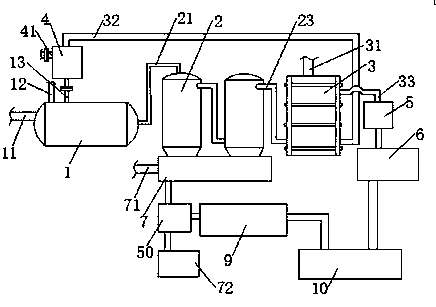

[0012] The present invention will be further described below in conjunction with the accompanying drawings.

[0013] like figure 1 As shown in , a glass solution heat recovery device for producing white carbon black includes a drum-type steaming ball 1, and the front end of the drum-type steaming ball 1 communicates with a steam pipe 11, a feed pipe 12 and a hot water pipe 13, and the drum The rear side of the type steaming ball 1 is connected to the buffer tower 2 by the discharge pipeline 21, and the bottom of the buffer tower 2 is provided with an alkali slag tank 7; the rear side of the buffer tower 7 is connected to the plate heat exchanger 3 through the hot material conduit 23, so The plate heat exchanger 3 is connected to the cold water inlet pipe 31, the hot water outlet pipe 32 and the cold material outlet pipe 33, the other end of the hot water outlet pipe 32 is connected to the hot water storage tank 4, and the hot water storage tank 4 is connected to the raw water ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com