Modified graphene based composite asphalt modifier and preparation method and application of modified graphene based composite asphalt modifier

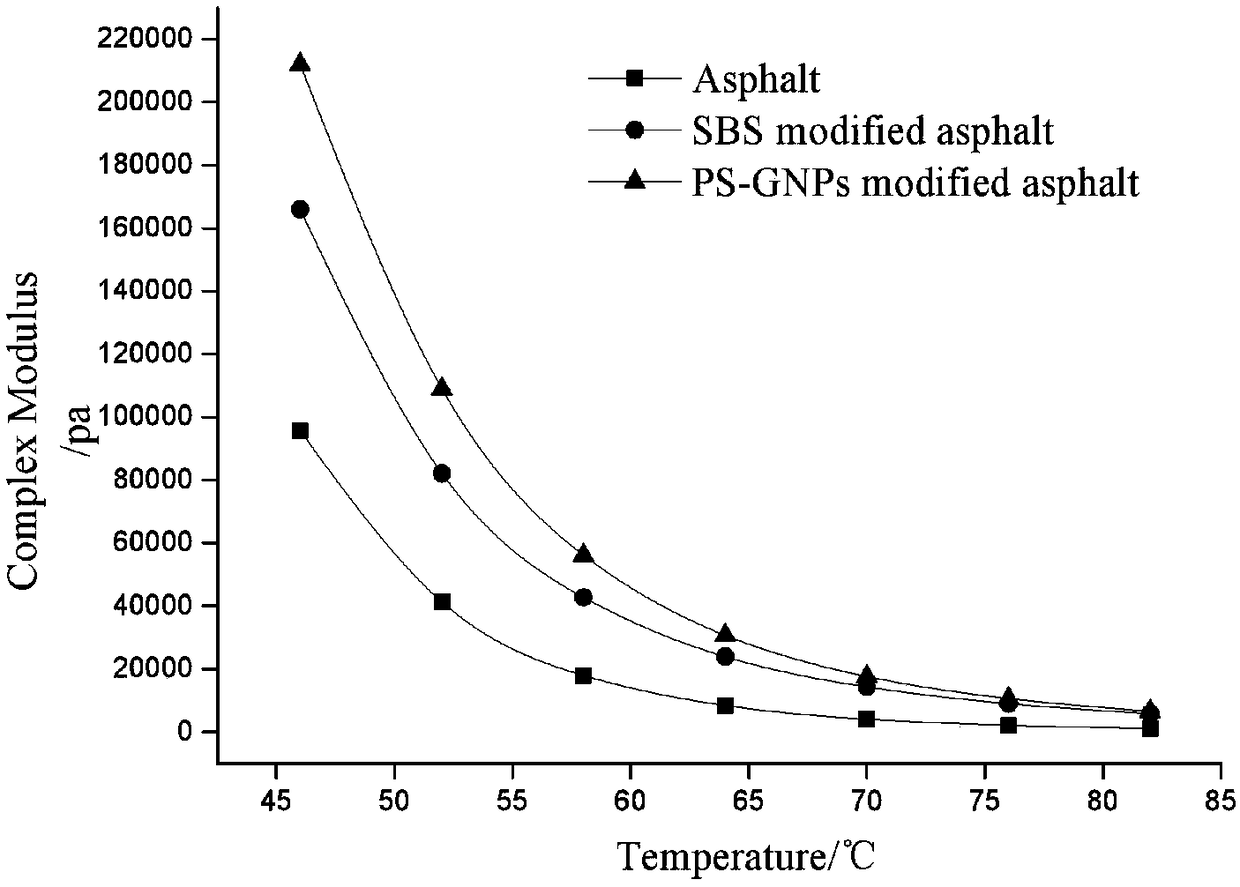

A technology of composite asphalt and modified asphalt, applied in building components, building thermal insulation materials, buildings, etc., can solve the problems of low stability, poor dispersibility, and decreased plasticity, achieve improved dispersibility and stability, and improved durability. High, elastic performance improvement effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0043] (1) Add 1 g of natural graphite flakes into a beaker, and add 24 mL of concentrated sulfuric acid (with a density of 1.836 g / cm3 ) and 12mL concentrated nitric acid (density 1.420g / cm 3 ), magnetically stirred for 10min to disperse evenly, to prevent graphite agglomeration, after uniform dispersion, slowly add 3gKMnO 4 , and kept stirring in an ice-water bath for 2 hours, the solution was dark green at this time;

[0044] (2) After raising the temperature of the solution obtained in (1) to 25°C and stirring for 30 minutes, slowly add 100 mL of deionized water to it, and raise the temperature to 80°C and stir for 10 minutes;

[0045] (3) Pour the solution in (2) into 200mL of deionized water at a temperature of 60°C, and add 10mL of H 2 o 2 (35%wt), the solution turned golden yellow. Put the solution for several times to collect the solid by suction filtration, add 15mL of 5% hydrochloric acid and dilute it with deionized water. After stirring evenly, the solution tur...

Embodiment 2

[0053] (1) 2g of natural flake graphite was added to a beaker, and 48mL of concentrated sulfuric acid (with a density of 1.836g / cm 3 ) and 24mL concentrated nitric acid (density 1.420g / cm 3 ), magnetically stirred for 20min to disperse evenly, to prevent graphite agglomeration, after uniform dispersion, slowly add 6gKMnO 4 , and kept stirring in an ice-water bath for 3 hours, the solution was dark green at this time;

[0054] (2) After the solution described in (1) was heated to 30°C and stirred for 45 minutes, 200 mL of deionized water was slowly added thereto, and the temperature was raised to 85°C and stirred for 25 minutes;

[0055] (3) Pour the solution in (2) into 300mL of deionized water at a temperature of 60°C, and add 20mL of H 2 o 2 (35%wt), the solution turns golden yellow, the solution is left to stand for several times to collect the solid by suction filtration, 30mL of 5% hydrochloric acid is added and the collected solid is diluted with deionized water, and ...

Embodiment 3

[0063] (1) 3g of natural flake graphite was added to a beaker, and 72mL of concentrated sulfuric acid (with a density of 1.836g / cm 3 ) and 36mL concentrated nitric acid (density 1.420g / cm 3 ), magnetically stirred for 30min to disperse evenly, to prevent graphite agglomeration, after uniform dispersion, slowly add 9gKMnO 4 , and kept stirring in an ice-water bath for 4 hours, the solution was dark green at this time;

[0064] (2) After the solution described in (1) was heated to 35°C and stirred for 60 minutes, 300 mL of deionized water was slowly added thereto, and the temperature was raised to 90°C and stirred for 30 minutes;

[0065] (3) Pour the solution in (2) into 400mL60°C deionized water, and add 30mLH 2 o 2 (35%wt), the solution turns golden yellow, the solution is left to stand for several times to collect the solid by suction filtration, adds 45mL of 5% hydrochloric acid and dilutes the collected solid with deionized water, the solution becomes light green after ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com