Novel anti-microbial edible aluminum foil

A new type of aluminum foil technology, applied in the field of aluminum alloy materials, can solve the problems of production and packaging process pollution, no antibacterial effect on the surface of aluminum foil, etc., and achieve the effect of reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0018] New antibacterial edible aluminum foil, the mass percentage of each component is: Si: 0.16%, Fe: 1.10%, Cu: 0.12%, Mn: 0.4%, Mg: 0.04%, Zn: 0.06%, Ti: 0.06%, Y: 0.06 %, the balance is Al.

[0019] The preparation method of described novel antibacterial edible aluminum foil comprises the following steps:

[0020] (1) adding the raw materials of each component of the aluminum alloy into a smelting furnace for smelting to obtain a molten aluminum alloy;

[0021] (2) Input the molten aluminum alloy into the casting and rolling machine, cast and roll it into a billet with a thickness of 8.5mm, and cool to room temperature;

[0022] (3) When the cast-rolled billet is cold-rolled by a cold-rolling mill to a thickness of 4.0mm, homogenization annealing treatment is performed, the annealing temperature is 580°C, and the holding time is 20h;

[0023] (4) After the homogenized annealed aluminum coil is cooled to room temperature, it is cold rolled to 1.7mm and 1.0mm in separate ...

Embodiment 2

[0031] New antibacterial edible aluminum foil, the mass percentage of each component is: Si: 0.14%, Fe: 1.50%, Cu: 0.15%, Mn: 0.3%, Mg: 0.03%, Zn: 0.04%, Ti: 0.04%, Y: 0.08 %, the balance is Al.

[0032] The preparation method of described novel antibacterial edible aluminum foil comprises the following steps:

[0033] (1) adding the raw materials of each component of the aluminum alloy into a smelting furnace for smelting to obtain a molten aluminum alloy;

[0034] (2) Input the molten aluminum alloy into the casting and rolling machine, cast and roll it into a billet with a thickness of 8.5mm, and cool to room temperature;

[0035] (3) When the cast-rolled billet is cold-rolled by a cold-rolling mill to a thickness of 4.0mm, homogenization annealing treatment is performed, the annealing temperature is 580°C, and the holding time is 20h;

[0036] (4) After the homogenized annealed aluminum coil is cooled to room temperature, it is cold rolled to 1.7mm and 1.0mm in separate ...

Embodiment 3

[0044] New antibacterial edible aluminum foil, the mass percentage of each component is: Si: 0.13%, Fe: 1.30%, Cu: 0.14%, Mn: 0.2%, Mg: 0.02%, Zn: 0.03%, Ti: 0.03%, Y: 0.07 %, the balance is Al.

[0045]The preparation method of described novel antibacterial edible aluminum foil comprises the following steps:

[0046] (1) adding the raw materials of each component of the aluminum alloy into a smelting furnace for smelting to obtain a molten aluminum alloy;

[0047] (2) Input the molten aluminum alloy into the casting and rolling machine, cast and roll it into a billet with a thickness of 8.5mm, and cool to room temperature;

[0048] (3) When the cast-rolled billet is cold-rolled by a cold-rolling mill to a thickness of 4.0mm, homogenization annealing treatment is performed, the annealing temperature is 580°C, and the holding time is 20h;

[0049] (4) After the homogenized annealed aluminum coil is cooled to room temperature, it is cold rolled to 1.7mm and 1.0mm in separate p...

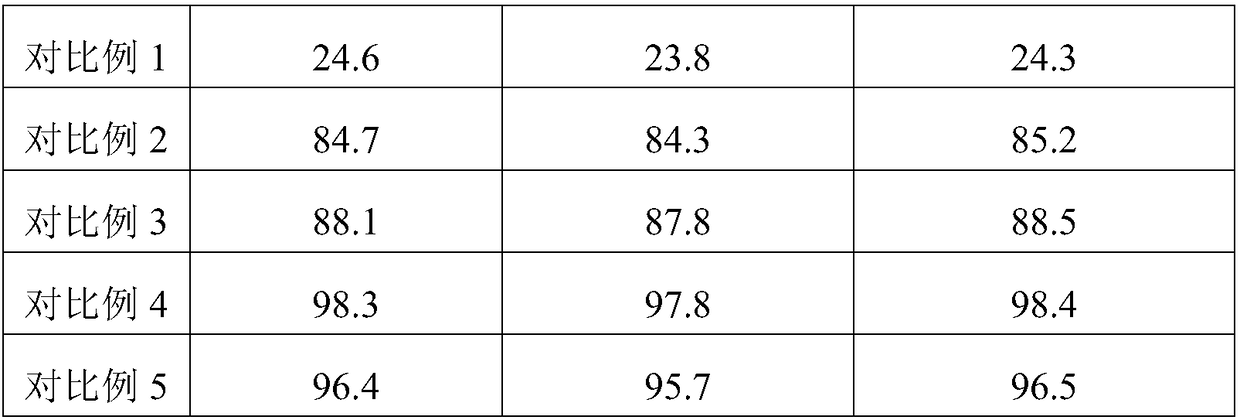

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com