Composite-rubber formaldehyde-free mildew-proof medium-density fiberboard and manufacturing process thereof

A manufacturing process and medium-density technology, applied in fiberboard, papermaking, textiles and papermaking, etc., can solve problems such as air pollution and mildew, and achieve the effects of improving production efficiency, promoting colloidal foaming, and increasing colloidal specific surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

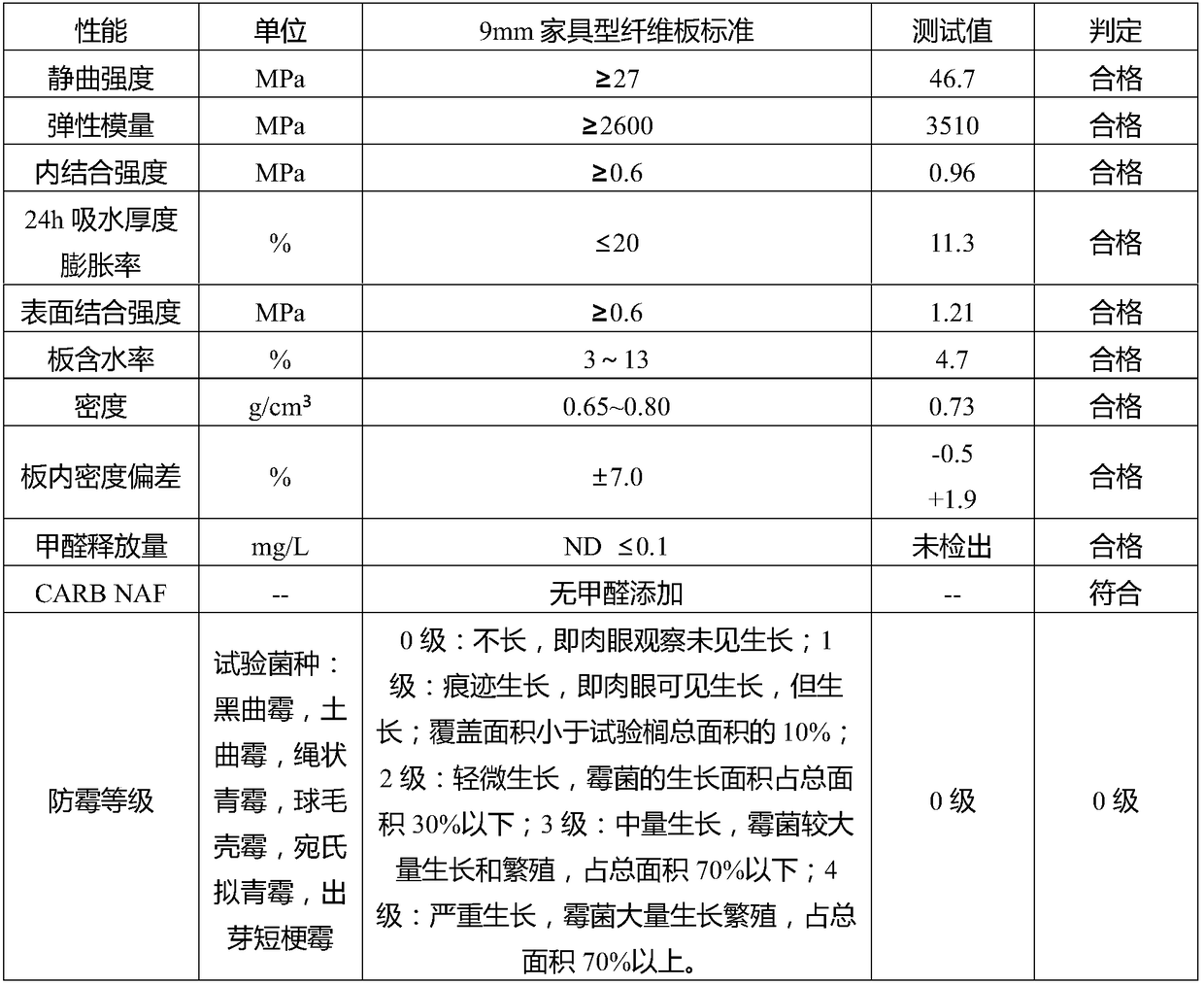

Embodiment 1

[0024] A kind of manufacturing technology of formaldehyde-free mildew-proof medium-density fiberboard with 9mm composite glue, the steps are as follows:

[0025] 1. Chipping: the wood is made into qualified wood chips with a length of 15-60 mm, a width of 15-30 mm, and a thickness of 3-6 mm through a chipping machine;

[0026] 2. Cooking and hot grinding: the wood chips are softened by cooking for 3 minutes, the temperature is about 170 ° C, and the pressure is 0.86 MPa; the softened wood chips are defibrated by a hot mill, and molten paraffin is added to the mill at the same time. The hot grinding temperature is 175 ° C. The pressure is 0.83MPa, and the amount of paraffin applied is 0.2% of the dry weight of the fiber;

[0027] 3. Sizing and drying: Mix aromatic water-based polyurethane with modified vegetable protein glue and cross-linking agent evenly through a static mixer, and then transport them to the spray pipe to mix with fibers evenly, among which aromatic water-base...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap