Industrial zirconium carbonate with high purity, high activity and good storage stability and preparation method thereof

A high-purity technology of zirconium carbonate, applied in chemical instruments and methods, zirconium compounds, pharmaceutical formulations, etc., can solve problems such as difficult control, narrow range of ammonium bicarbonate mass ratio, cross-linking failure, etc., and achieve the goal of reducing the amount of acid Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

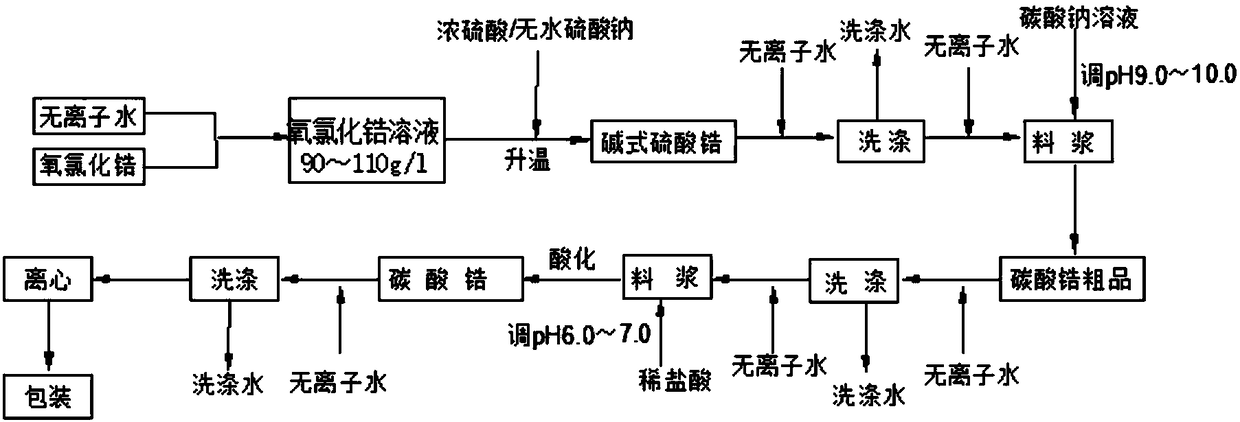

[0118] The invention relates to a method for preparing industrial zirconium carbonate with high purity, high activity and good storage stability. Including the following steps:

[0119] ①. Preparation of basic zirconium sulfate

[0120] a. Preparation of zirconium oxychloride solution

[0121] In the stirring reaction kettle, drop into deionized water and zirconium oxychloride, stir and dissolve, and prepare a zirconium oxychloride aqueous solution of 110g / l;

[0122] b. Preparation of basic zirconium sulfate

[0123] Under stirring, add concentrated sulfuric acid or anhydrous sodium sulfate dropwise to the zirconium oxychloride aqueous solution prepared in item a to control SO 4 2- : ZrO 2 The molar ratio is 0.7, the heating rate is controlled at 1°C / min, the temperature rises to 90°C, and at 90°C, the reaction is kept for 1 to 1.5 hours, and the filter is prepared;

[0124] c. Filtration, washing, pulping

[0125] Step 1. The basic zirconium sulfate feed solution prep...

Embodiment 2

[0143] The invention relates to a method for preparing industrial zirconium carbonate with high purity, high activity and good storage stability. Including the following steps:

[0144] ①. Preparation of basic zirconium sulfate

[0145] a. Preparation of zirconium oxychloride solution

[0146] In the stirred reactor, drop into deionized water and zirconium oxychloride, stir and dissolve, and prepare a 90g / l zirconium oxychloride aqueous solution;

[0147] b. Preparation of basic zirconium sulfate

[0148] Under stirring, add concentrated sulfuric acid or anhydrous sodium sulfate dropwise to the zirconium oxychloride aqueous solution prepared in item a to control SO 4 2- : ZrO 2 The molar ratio is 0.6, the heating rate is controlled at 1°C / min, the temperature rises to 90°C, and at 90°C, the reaction is kept for 1 to 1.5 hours, and the filter is prepared;

[0149] c. Filtration, washing, pulping

[0150] Step 1. The basic zirconium sulfate feed solution prepared in step ...

Embodiment 3

[0169] ①. Preparation of basic zirconium sulfate

[0170] a. Preparation of zirconium oxychloride solution

[0171] In the stirred reactor, drop into deionized water and zirconium oxychloride, stir and dissolve, and prepare a 100g / l zirconium oxychloride aqueous solution;

[0172] b. Preparation of basic zirconium sulfate

[0173] Under stirring, add concentrated sulfuric acid or anhydrous sodium sulfate dropwise to the zirconium oxychloride aqueous solution prepared in item a to control SO 4 2- : ZrO 2 The molar ratio is 0.65, the heating rate is controlled at 1°C / min, the temperature rises to 90°C, and at 90°C, the reaction is kept for 1 to 1.5 hours, and the filter is prepared;

[0174] c. Filtration, washing, pulping

[0175] Step 1. The basic zirconium sulfate feed solution prepared in step 1 is filtered by a belt-type vacuum filter washing machine, and the filter cake is continuously washed with deionized water under vacuum until the pH is qualified, and an appropri...

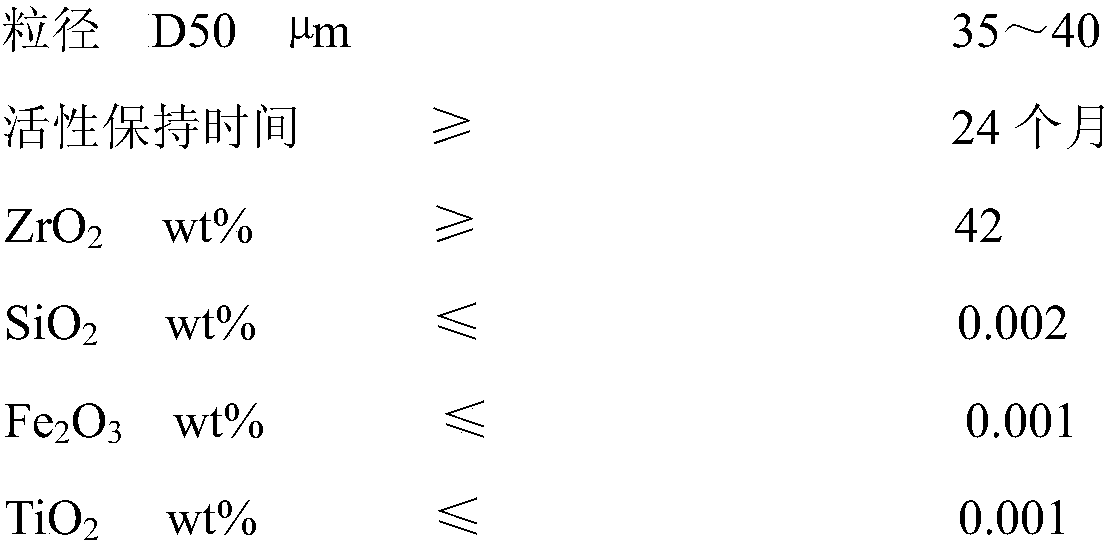

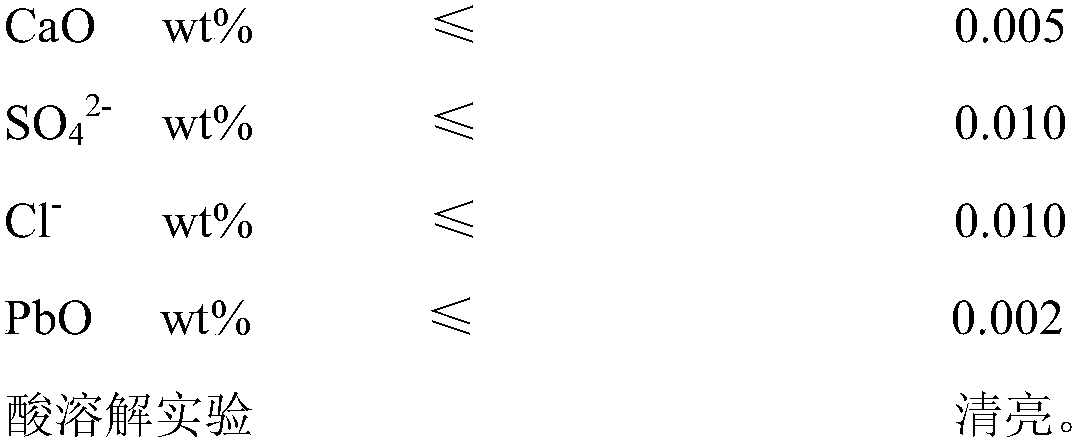

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com