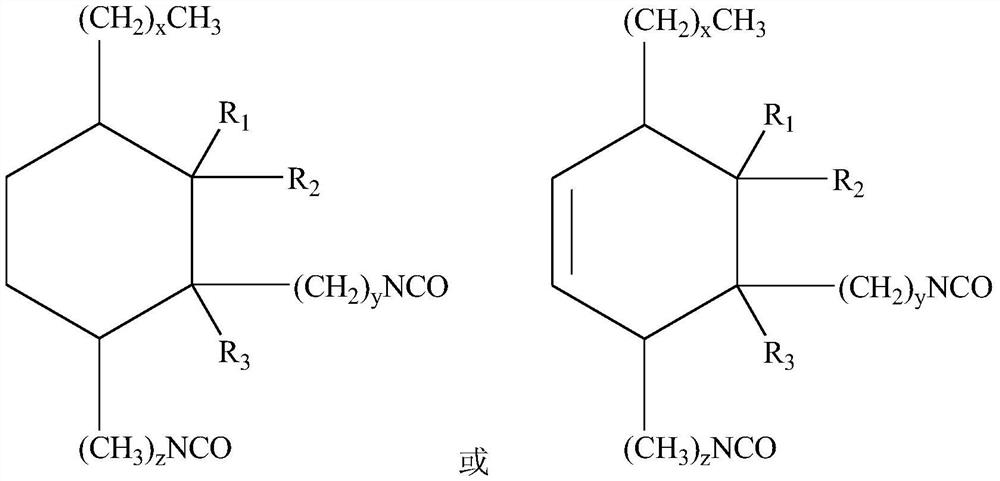

Method for Solving Post-curing Problem of Room Temperature Curing Butyl Hydroxyl Propellant and Prepared Product

A room temperature curing and propellant technology, which is used in the field of solid rocket propellants and missile weapons, can solve problems such as post-curing, and achieve the effect of improving aging performance and solving post-curing problems.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

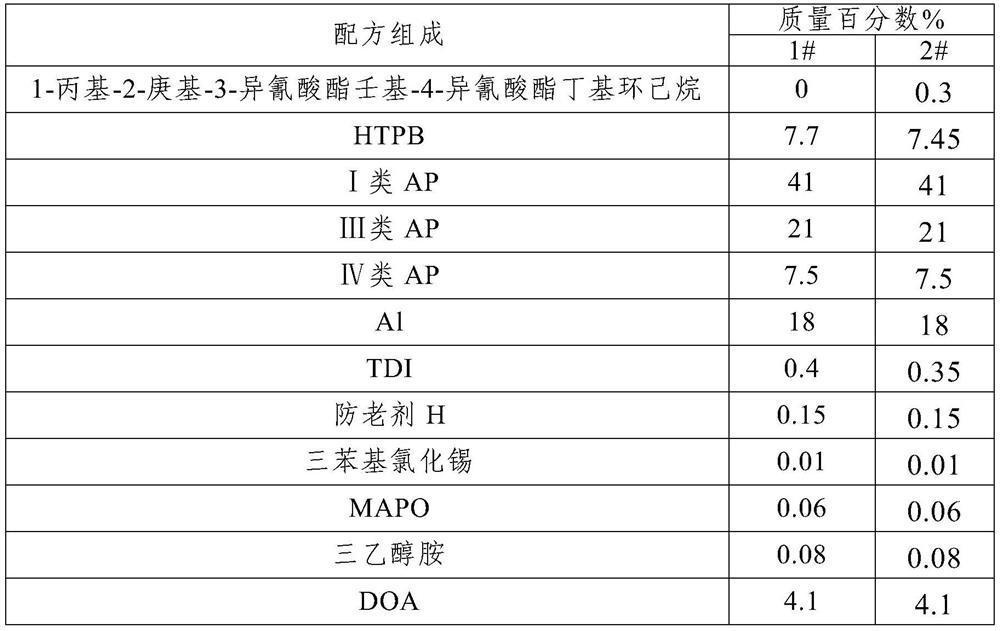

[0041] The formula (mass percentage) of room temperature curing propellant is as shown in table 1:

[0042] Table 1 Room temperature curing propellant formulation

[0043]

[0044] As can be seen from Table 1, compared with the prior art room temperature curing propellant formula (1#), in the formula (2#) of the room temperature curing propellant of the present invention, only 0.3% of 1-propyl-2 -Heptyl-3-isocyanatenonyl-4-isocyanatebutylcyclohexane. Table 2 shows the room temperature mechanical properties of the propellant cured for different days at 35°C.

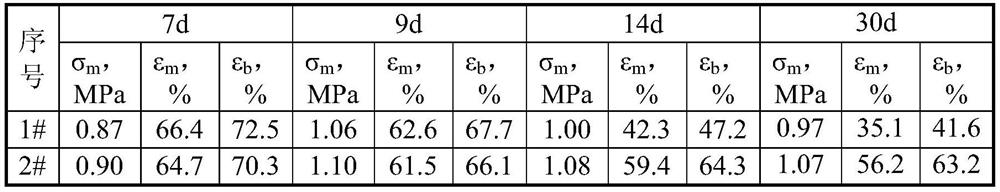

[0045] Table 2 Room temperature mechanical properties of room temperature curing propellants (cured at 35°C)

[0046]

[0047] As can be seen from Table 2, the initial mechanical properties of the room temperature curing propellant and prior art formulations and the attainment of vulcanization by adding auxiliary agent 1-propyl-2-heptyl-3-isocyanate nonyl-4-isocyanate butyl cyclohexane The point time is comparabl...

Embodiment 2

[0049] The formula (mass percentage) of room temperature curing propellant is as shown in table 3:

[0050] Table 3 Room temperature curing propellant formulation

[0051]

[0052] As can be seen from Table 3, compared with the prior art room temperature curing propellant formula (3#), in the improved room temperature curing propellant formula (4#), 0.4% 1-butyl-2- Octyl-3,4-bis(isocyanatooctyl)cyclohexane. The room temperature mechanical properties and initial accelerated aging properties of the propellant cured at 40°C for different days are shown in Table 4. Table 4 also lists the mechanical properties of the propellant cured at 50°C for the improved propellant formulation .

[0053] Table 4 Normal temperature mechanical properties of room temperature curing propellants

[0054]

[0055] It can be seen from Table 4 that the room temperature curing propellant added with auxiliary agent 1-butyl-2-octyl-3,4-bis(isocyanate octyl)cyclohexane is cured at 40°C and cured a...

Embodiment 3

[0057] The formula (mass percentage) of room temperature curing propellant is as shown in table 5:

[0058] Table 5 Room temperature curing propellant formulation

[0059]

[0060] As can be seen from Table 5, compared with the prior art room temperature curing propellant formula (5#), in the formula (6#) of the room temperature curing propellant of the present invention, 0.3% of 1-pentyl-2- Nonyl-3,4-bis(isocyanatoheptyl)cyclohexane. Table 6 shows the room temperature mechanical properties of the propellant cured for different days at 35°C.

[0061] Table 6 Room temperature mechanical properties of room temperature curing propellants (cured at 35°C)

[0062]

[0063] As can be seen from Table 6, the room temperature curing propellant of the present invention with the addition of auxiliary agent 1-pentyl-2-nonyl-3,4-bis(isocyanatoheptyl)cyclohexane is compared with the room temperature curing propellant of the prior art , the initial mechanical properties and the time...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com