Method for Batch Synthesis of Water-dispersed Small Size Ultra-Long Near Infrared Afterglow Nanoparticles

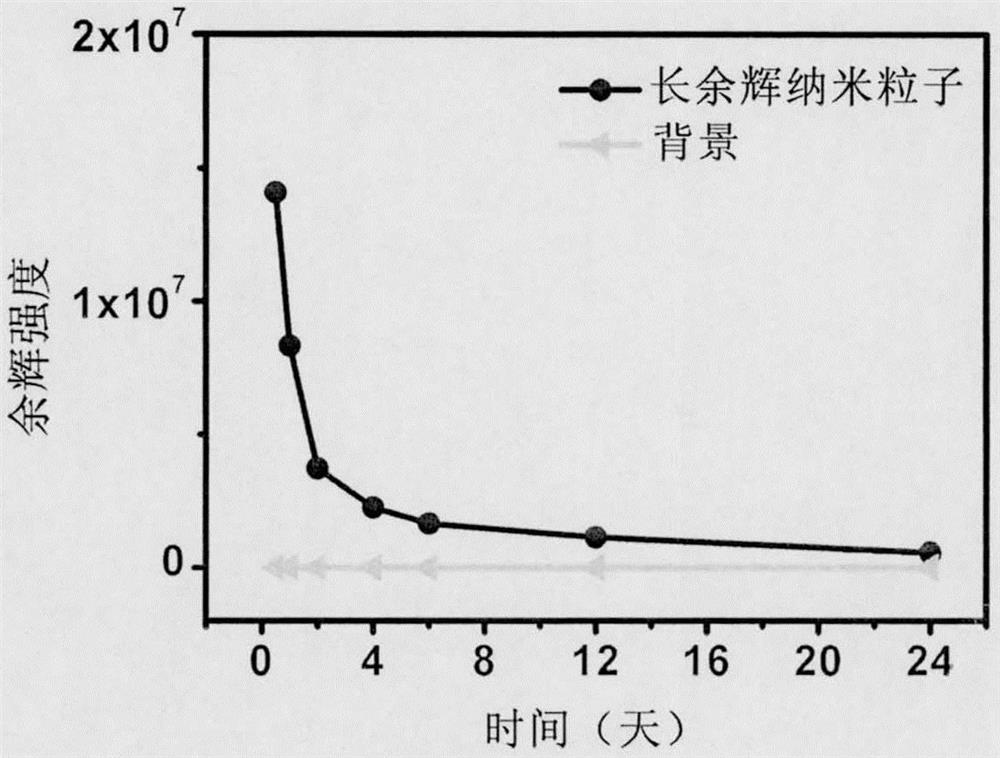

A nanoparticle and small particle size technology, applied in nanotechnology, nano optics, nanotechnology, etc., can solve the problems of low yield and poor water dispersibility of materials, and achieve better water dispersibility, small particle size, and signal-to-noise The effect of improving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

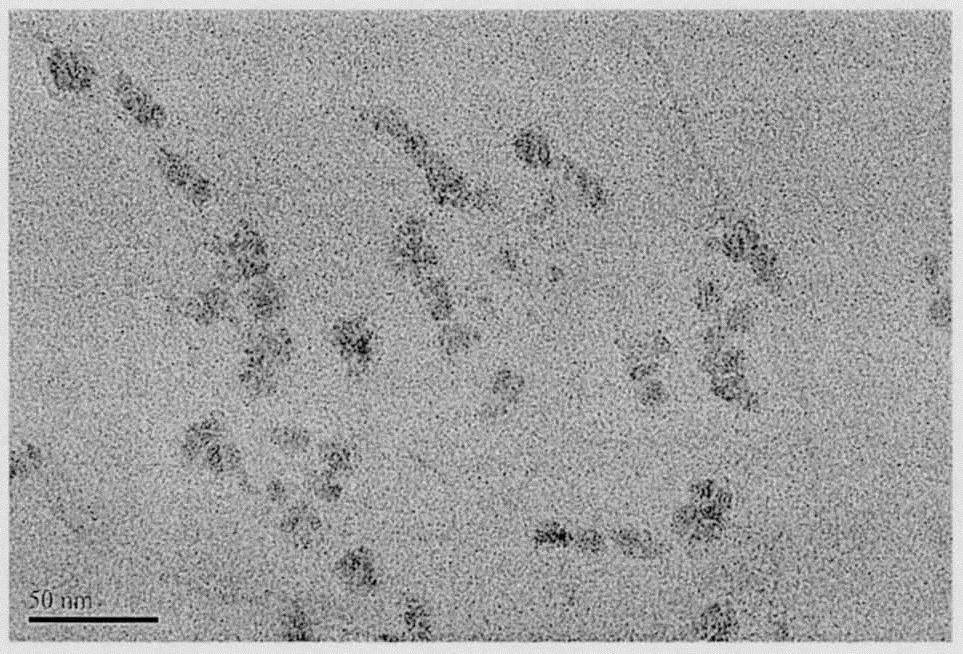

[0014] A method for batch synthesis of water-dispersed small-size, ultra-long near-infrared afterglow nanoparticles. The method is characterized in that the long afterglow nanoparticles calcined at high temperature are synthesized in batches by using a metal complexing agent solution for hydrothermal post-treatment. Proceed as follows:

[0015] 1) According to the general chemical formula ZnGa 2 o 4 : Cr 0.004 , mix Zn, Ga, Cr with a molar ratio of 1:2:0.004 nitrate solution, and then adjust the solution to be alkaline with tert-butylamine.

[0016] 2) Put the above solution, the same amount of toluene and 2mL oleic acid into a 50mL Teflon-lined reaction kettle, and put it in an oven at 160°C for 24 hours to react.

[0017] 3) The above suspension was poured into ethanol and then centrifuged, and the obtained precipitate was washed twice with ethanol and water respectively, and then dried at 80°C.

[0018] 4) Calcining the above solid in a muffle furnace at 1000° C. for 1...

Embodiment 2

[0026] A method for batch synthesis of water-dispersed small-size, ultra-long near-infrared afterglow nanoparticles. The method is characterized in that the long afterglow nanoparticles calcined at high temperature are synthesized in batches by using a metal complexing agent solution for hydrothermal post-treatment. Steps and methods are basically the same as in Example 1, except that the chemical general formula of long afterglow in step 1 is Zn 3 Ga 2 Ge 2 o 10 : Cr 0.004 , the proportion of metal nitrate added changes accordingly. The detection result of the prepared nanomaterial is similar to that of Example 1.

Embodiment 3

[0028] A method for batch synthesis of water-dispersed small-size, ultra-long near-infrared afterglow nanoparticles. The method is characterized in that the long afterglow nanoparticles calcined at high temperature are synthesized in batches by using a metal complexing agent solution for hydrothermal post-treatment. The steps and method are basically the same as in Example 1, except that the difference is that the general chemical formula of long afterglow in step 1 is Zn 5 Ga 6 GeO 16 : Cr 0.02 Yb 0.1 Er 0.01 , the proportion of metal nitrate added changes accordingly. The detection result of the prepared nanomaterial is similar to that of Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com