Production method of ultra-precise and long-life mold

A production method and long-life technology, applied in the direction of manufacturing tools, heat treatment equipment, furnaces, etc., can solve the problems of easy loss of processing tools, high tool cost, high mold material cost, and achieve high knife edge matching accuracy, short knife edge processing cycle, The effect of low cost of mold material

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

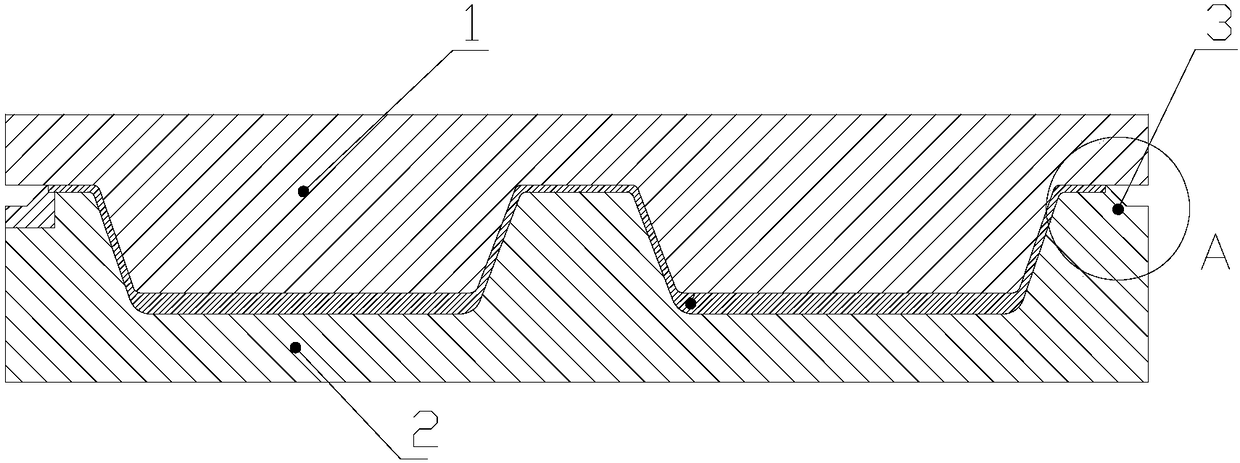

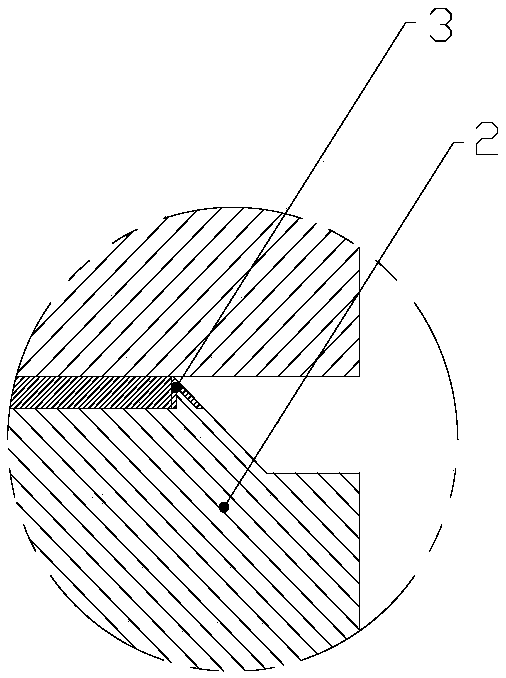

Image

Examples

Embodiment 1

[0032] A method of manufacturing ultra-precision long-life molds. Firstly, rough machining is carried out on the edge of the mold. After the rough machining is completed, the stress release of the mold core is released by lowering the machine tool, and then the mold core and the knife edge are put on the machine tool together for finishing machining, thereby completing the mold body. At this time, the hardness of the knife edge is 20Hrc, and then the laser quenching is used to process the knife edge, and the following steps are specifically adopted:

[0033] Place the mold on the workbench of the laser hardening equipment, use the manipulator to program the trajectory memory along with the shape of the mold, and then irradiate the laser beam on the knife edge to perform knife edge quenching. At this time, a laser head with a laser beam width of 5mm is required. The temperature is set at 1100°C, the distance between the laser head and the knife edge is equal and constant at 240m...

Embodiment 2

[0039] A method of manufacturing ultra-precision long-life molds. Firstly, rough machining is carried out on the edge of the mold. After the rough machining is completed, the stress release of the mold core is released by lowering the machine tool, and then the mold core and the knife edge are put on the machine tool together for finishing machining, thereby completing the mold body. Production, at this time the hardness of the knife edge is 15Hrc, and then laser quenching is used to process the knife edge. The laser beam is irradiated on the knife edge, and the temperature of the laser beam is controlled to be 1000°C. The laser beam is output through a laser head with a width of 5 mm. During the processing, the distance between the laser head and the upper surface of the knife edge is always kept constant. This implementation In the example, the distance between the laser head and the upper surface of the knife edge is 230mm, the laser beam is controlled to move at a speed of ...

Embodiment 3

[0041] A method of manufacturing ultra-precision long-life molds. Firstly, rough machining is carried out on the edge of the mold. After the rough machining is completed, the stress release of the mold core is released by lowering the machine tool, and then the mold core and the knife edge are put on the machine tool together for finishing machining, thereby completing the mold body. At this time, the hardness of the knife edge is 30Hrc, and then laser quenching is used to process the knife edge. The specific steps are as follows: place the mold with the knife edge on the workbench, use the manipulator to follow the trajectory memory programming of the shape of the mold, and then pass the laser The laser beam is irradiated on the knife edge, and the temperature of the laser beam is controlled to be 1200°C. The laser beam is output through a laser head with a width of 10 mm. During the processing, the distance between the laser head and the upper surface of the knife edge is alwa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com