A kind of dyeing agent for wool leather and dyeing process of wool leather

A process and wool leather technology, applied in the field of leather processing, can solve the problems of long time-consuming dyeing process, large changes in wool color, and difficult to control, and achieve the effect of meeting the requirements of rubbing color fastness, large changes in wool color, and improving quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

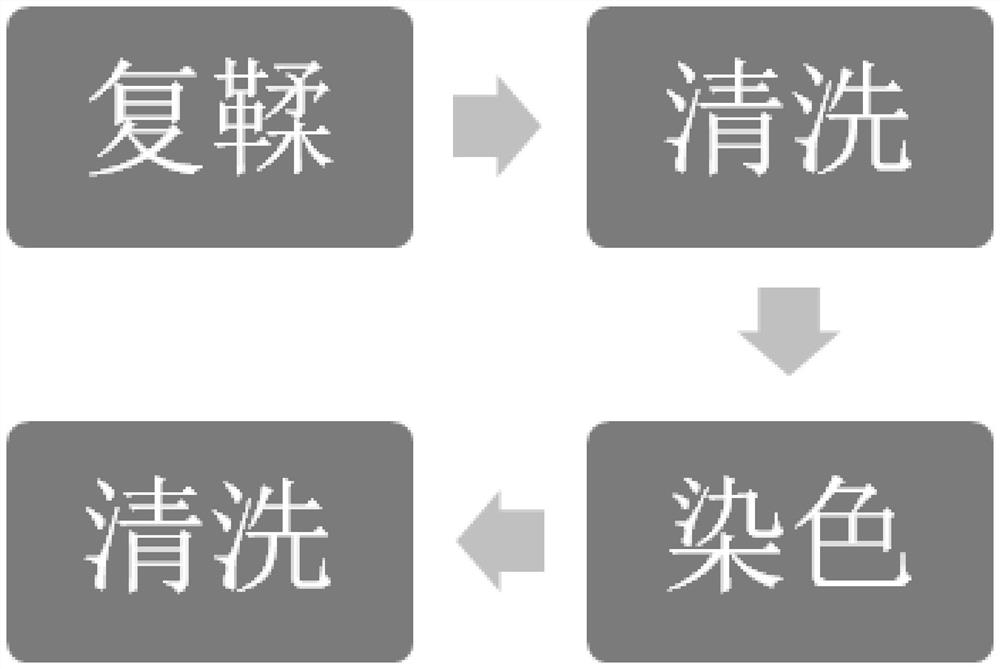

Method used

Image

Examples

Embodiment 1

[0126] 1) Put the skin into the inclined drum, the liquid ratio is 1:15, the temperature is 38°C, add 0.5g / L MPC, rotate for 30 minutes, add 0.5g / L GC, 1g / L IPF, 0.5g / L UPH and 1g / L SL and rotate for 60 minutes, add 1g / L formic acid, rotate for 20 minutes, add chromium powder 5g / L, rotate for 90 minutes, then add sodium formate 2g / L, rotate for 30 minutes, drain.

[0127] 2) Add water at 25°C to the inclined drum, the liquid ratio is 1:15, add 0.5g / L formic acid, wash for 10 minutes, and drain.

[0128] 3) Add water at 25°C to the inclined drum with a liquid ratio of 1:15, wash for 10 minutes, and drain.

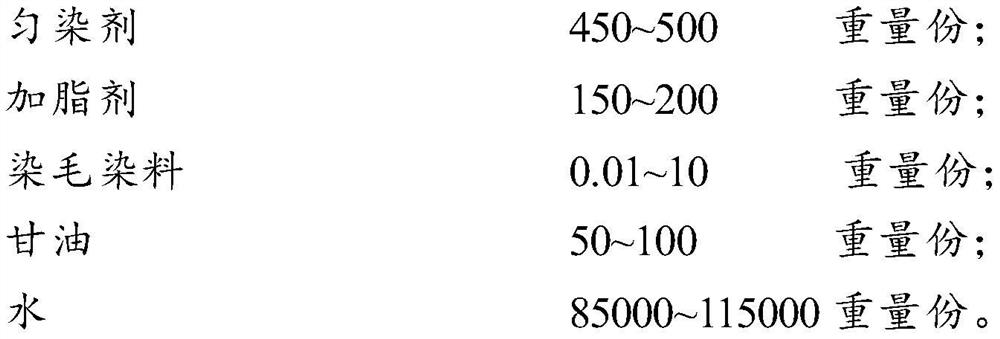

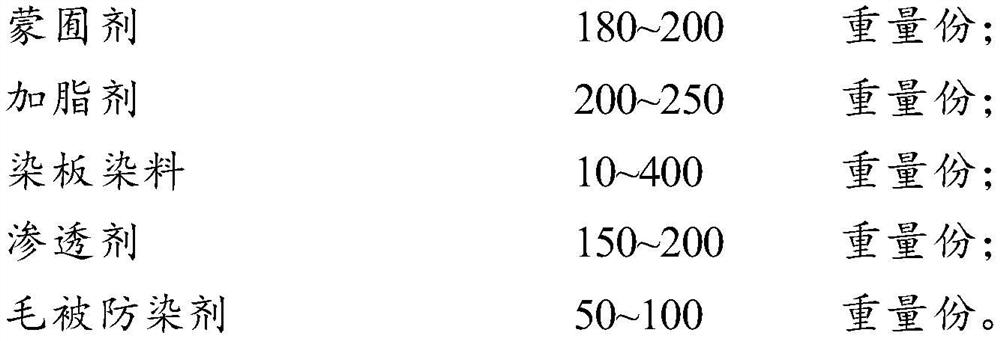

[0129] 4) Add 65°C water to the inclined drum, the liquid ratio is 1:15, add 2g / L FL-1, 3g / L nitric acid, 1.5g / L ammonia water and rotate for 60 minutes, adjust the pH=6.5, add 1g / L TN rotates for 20 minutes, add hair dye and dyeing board dye at the same time, and add glycerin 0.5g / L, 30 minutes, add glacial acetic acid 0.5g / L, rotate for 20 minutes, add fatliquor 0.5g / L L...

Embodiment 2

[0136] 1) Put the skin into the inclined drum, the liquid ratio is 1:15, the temperature is 38°C, add 0.5g / L MPC, rotate for 30 minutes, add 0.5g / L GC, 0.5g / L UPH and 1g / L The SL rotates for 60 minutes, adds 1g / L formic acid, rotates for 20 minutes, adds chromium powder 5g / L, rotates for 90 minutes, then adds sodium formate 2g / L, rotates for 30 minutes, and drains water.

[0137] 2) Add water at 25°C to the inclined drum, the liquid ratio is 1:15, add 0.5g / L formic acid, wash for 10 minutes, and drain.

[0138] 3) Add water at 25°C to the inclined drum with a liquid ratio of 1:15, wash for 10 minutes, and drain.

[0139] 4) Add 65°C water to the inclined drum, the liquid ratio is 1:15, add 1.8g / L FL-1, 3g / L nitric acid, 2g / L ammonia water and rotate for 60 minutes, adjust the pH=6.2, add 1g / L TN rotates for 20 minutes, add hair dye and dyeing board dye at the same time, and add glycerin 1g / L for 30 minutes, add glacial acetic acid 0.5g / L, rotate for 20 minutes, add fatliquor ...

Embodiment 3

[0146] 1) Put the skin into the inclined drum, the liquid ratio is 1:15, the temperature is 38°C, add 0.5g / L MPC, rotate for 30 minutes, add 0.5g / L GC, 1g / L IPF, 0.5g / L UPH and 1g / L SL and rotate for 60 minutes, add 1g / L formic acid, rotate for 20 minutes, add chromium powder 5g / L, rotate for 90 minutes, then add sodium formate 2g / L, rotate for 30 minutes, drain.

[0147] 2) Add water at 25°C to the inclined drum, the liquid ratio is 1:15, add 0.5g / L formic acid, wash for 10 minutes, and drain.

[0148] 3) Add water at 25°C to the inclined drum with a liquid ratio of 1:15, wash for 10 minutes, and drain.

[0149]4) Add water at 65°C to the inclined drum, the liquid ratio is 1:15, add 1.8g / L FL-1, 3g / L nitric acid, 1.5g / L ammonia water and rotate for 60 minutes, adjust the pH=6.5, Add 1g / L TN and rotate for 20 minutes, add hair dye and board dye at the same time, add glycerin 0.5g / L, 30 minutes, add 0.5g / L glacial acetic acid, rotate for 20 minutes, add fatliquor 0.5g / L TIS,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com