E glass fiber paper for CEM-3 copper-clad plate and manufacturing method of E glass fiber paper

A glass fiber paper and glass fiber technology, applied in the direction of synthetic cellulose/non-cellulose material pulp/paper, non-fiber pulp addition, fiber raw material treatment, etc., can solve problems not related to the E-glass fiber paper process, etc. Achieve the effect of white appearance, good compatibility and good dimensional stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0064] This embodiment is an E-glass fiber paper for CEM-3 copper clad board, which is composed of glass fiber and binder, wherein the glass fiber is 87%-91%, and the binder is 9%-13% ; The percentages stated are percentages by weight. The adhesive is epoxy resin.

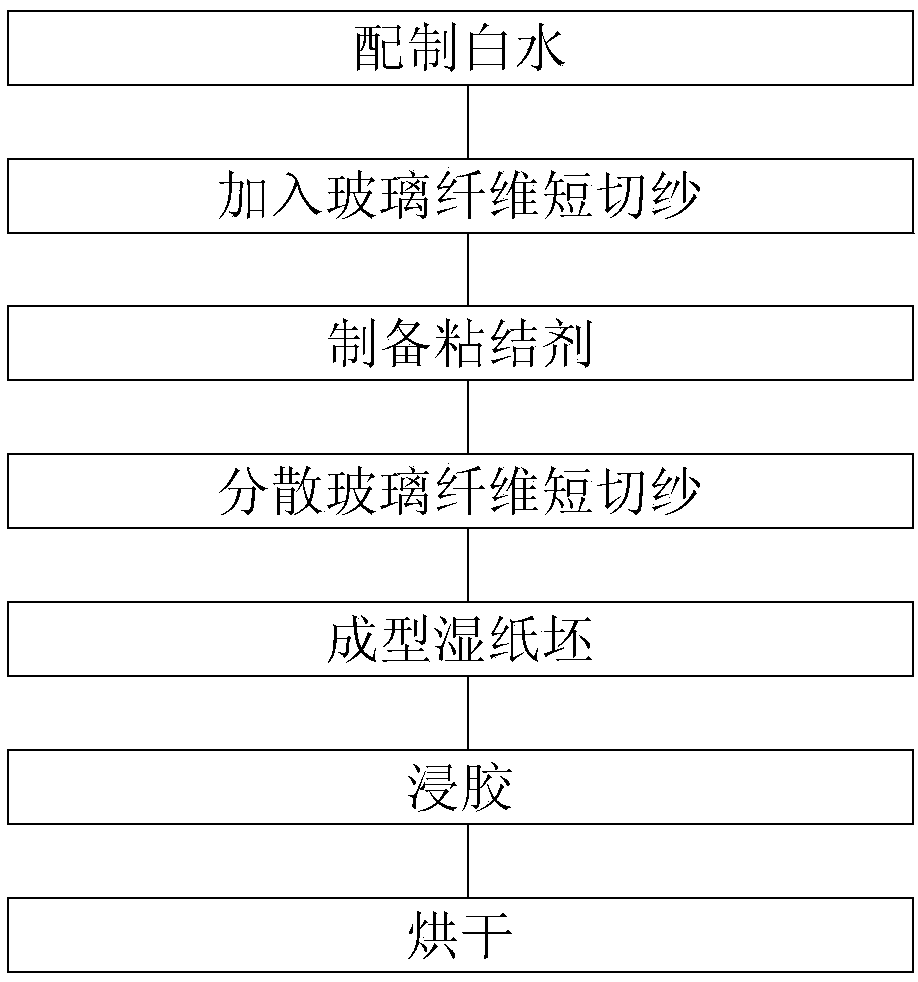

[0065] This embodiment also proposes a method for preparing the E glass fiber paper used for CEM-3 copper clad board, the specific process is:

[0066] Step 1, prepare white water.

[0067] The raw materials for preparing white water are thickener, dispersant, defoamer and deionized water. Among them, the thickener is 0.1-0.16%, the dispersant is 0.01%, and the deionized water is more than 99.8%. The content of the defoamer is added according to the amount of foam in the prepared white water to eliminate the foam.

[0068] Described thickening agent is hydroxyethyl cellulose ether, adopts the product of Union Carbide Company of the United States. The pH value of the aqueous solution is 6.0-8.5.

[0069] The d...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com