A dual-frequency feed horn including a metal ring

A feed horn, metal ring technology, applied to waveguide horns, devices that make antennas work in different bands at the same time, antennas, etc., can solve the problems of high operation and maintenance requirements, large equipment volume, etc. Transmission characteristics, saving processing costs, and the effect of good impedance matching

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

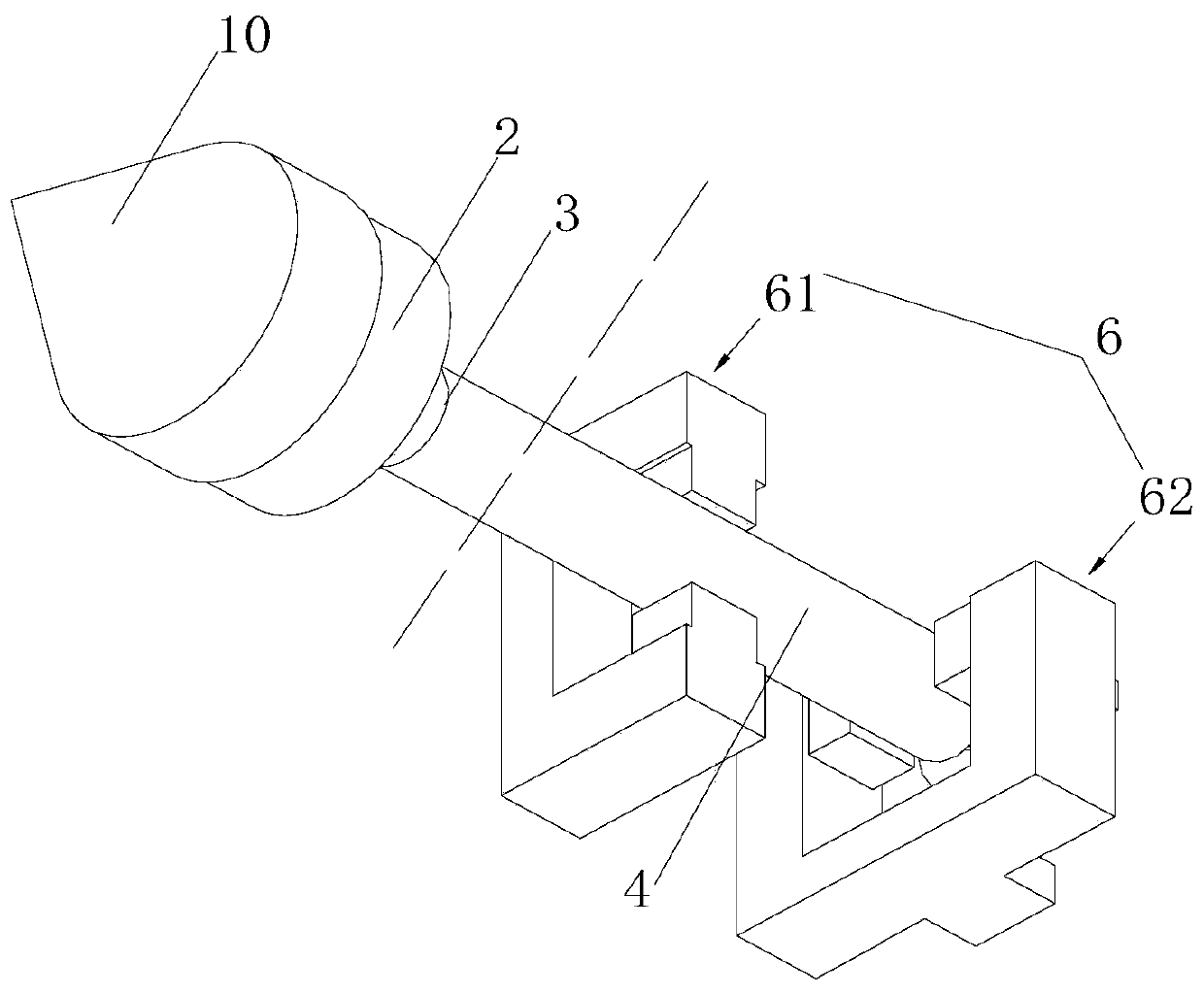

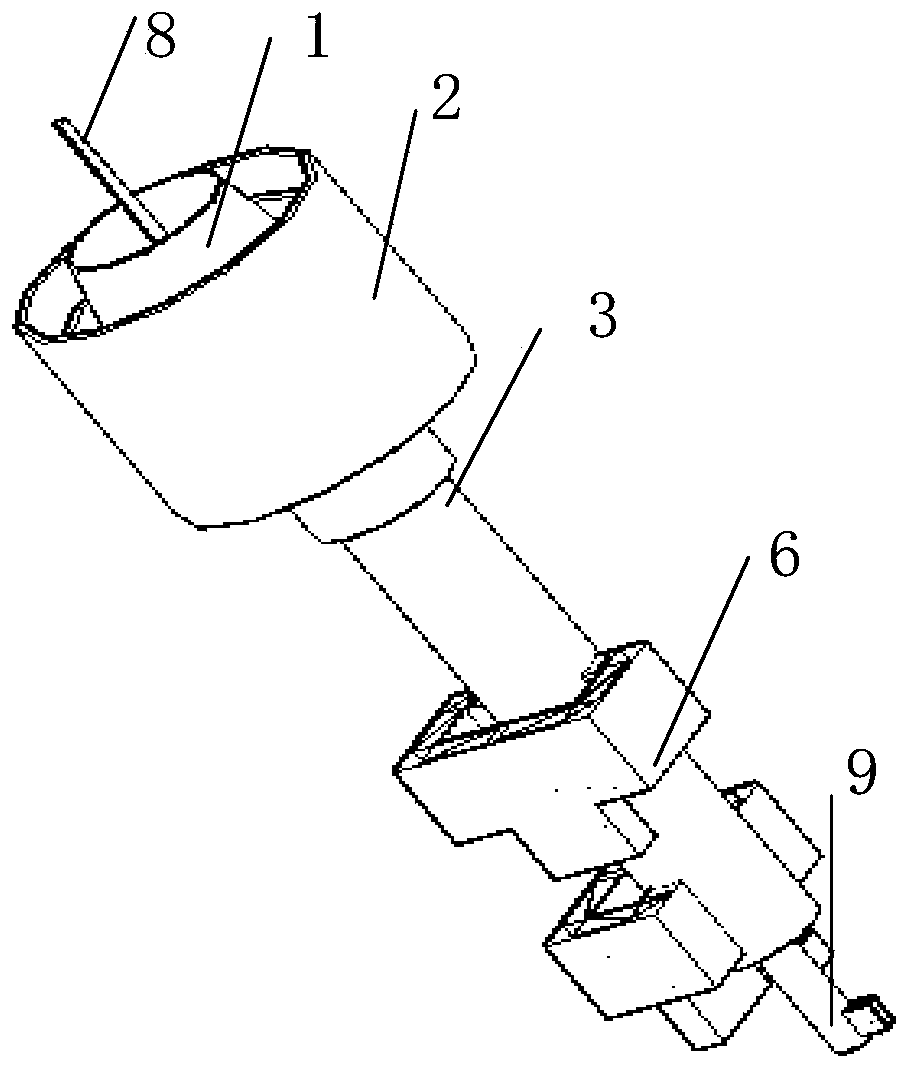

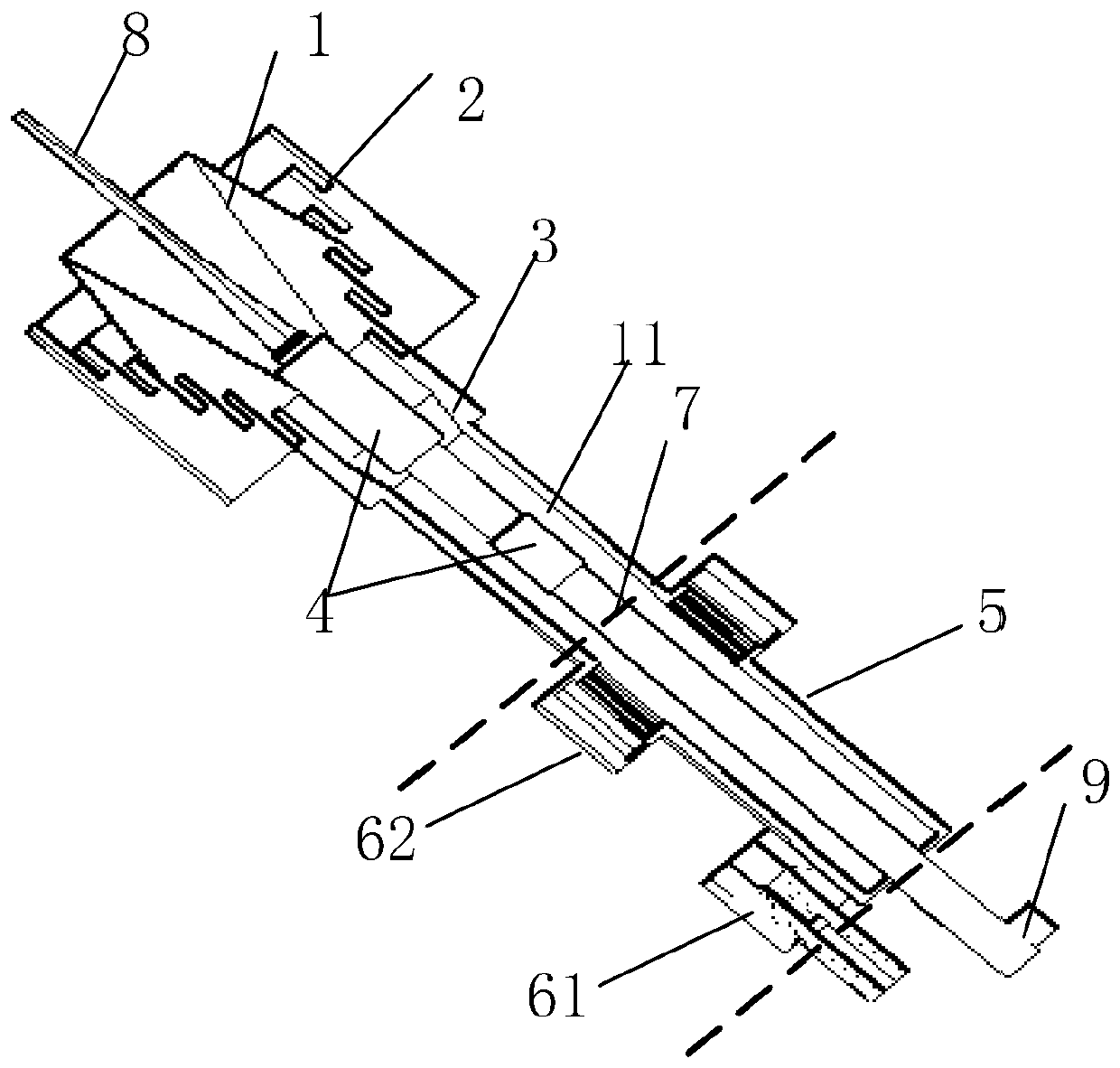

[0047] Such as Figure 1-4 As shown, a dual-frequency feed horn including a metal ring includes a first frequency band feed horn, a metal ring 4 for impedance matching, a second frequency band dielectric rod 8, a second frequency band circular waveguide 7, and a second frequency band positive Cross mode 9. The first band feed horn includes a first band vertical corrugated horn 2 as a radiating section 83, a first band variable diameter section 3 as an opening angle section, a first band waveguide transition section 5, and a first band waveguide transition section arranged in sequence An incentive structure 6 is also provided on 5.

[0048] The second frequency band circular waveguide 7 is coaxially arranged in the first frequency band feed horn. The signals of the first frequency band pass through the second frequency band formed between the outer surface of the second frequency band circular waveguide 7 and the cavity sidewall of the first frequency band feed horn. A cavity 11...

Embodiment 2

[0065] The difference from Embodiment 1 is that the included angle range between the first frequency band reducing section 3 and the central axis of the dual-frequency feed horn is 0°.

Embodiment 3

[0067] The difference from Embodiment 1 is that the included angle range between the first frequency band reducing section 3 and the central axis of the dual-frequency feed horn is 10°.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com