Epoxy resin composition, film-shaped epoxy resin composition, and electronic device

A technology of epoxy resin and composition, applied in circuits, electrical components, electrical solid devices, etc., can solve the problem of unfilled parts, achieve warpage suppression, excellent heat resistance and flame retardancy, and excellent handleability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~5 and comparative example 1~4、6

[0123] (Production of film-like epoxy resin composition)

[0124] The compounds shown in Table 1 and Table 2 were prepared as components constituting the film-like epoxy resin composition. The details of each component are as follows.

[0125] (A) epoxy resin

[0126] [Components that are liquid at 25°C]

[0127] A1: Bisphenol F-type epoxy resin (epoxy equivalent: 160, manufactured by Mitsubishi Chemical Corporation, trade name "jER806")

[0128] A2: bifunctional naphthalene-type epoxy resin (epoxy equivalent: 141, manufactured by DIC Corporation, trade name "HP-4032D", compound represented by the following formula)

[0129] [chemical 9]

[0130]

[0131] [Components that are not liquid at 25°C]

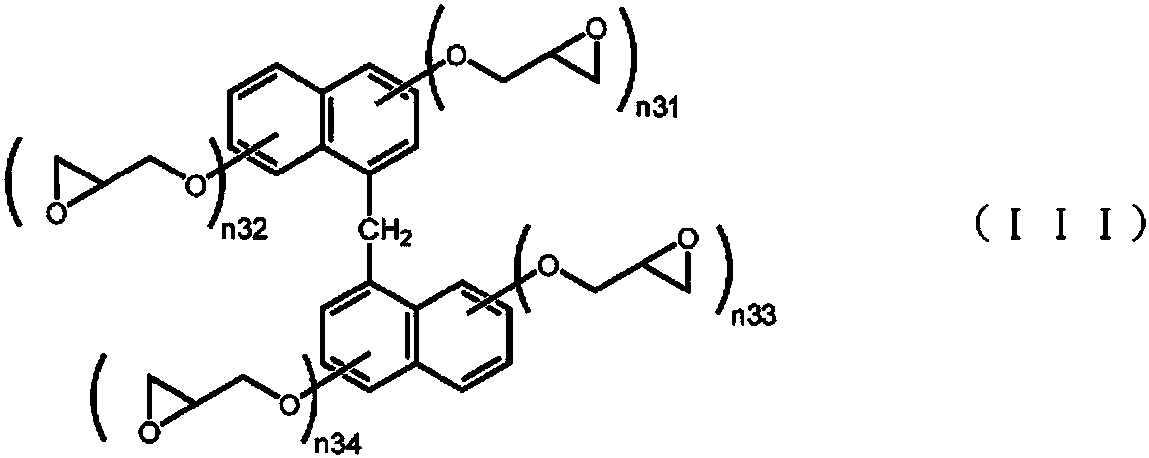

[0132] A3: Trifunctional naphthalene-type epoxy resin (epoxy equivalent: 182, manufactured by DIC Corporation, trade name "HP-4750", compound represented by formula (IV))

[0133] (B) Resin with aromatic ring and hydroxyl group

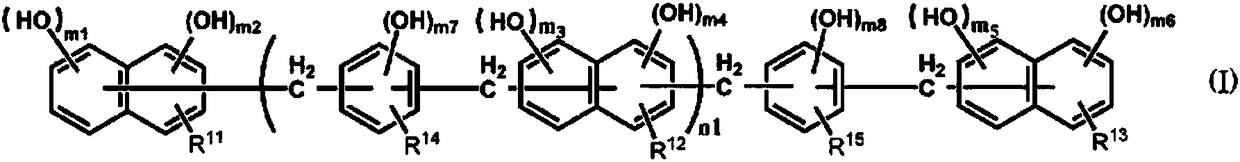

[0134] [Resin having naphthalene ring and hy...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap