Solid polymer electrolyte and method for producing same

A solid polymer and electrolyte technology, applied in solid electrolytes, electrolytes, non-aqueous electrolytes, etc., can solve the problems of ion conductivity reduction, liquefaction, etc., and achieve the effect of improving mechanical strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

[0113] Hereinafter, the present invention will be described in detail through specific examples. However, the descriptions provided herein are only preferred examples for the purpose of illustration and are not intended to limit the scope of the present invention, so it should be understood that these examples are provided to provide a clearer explanation to those skilled in the art.

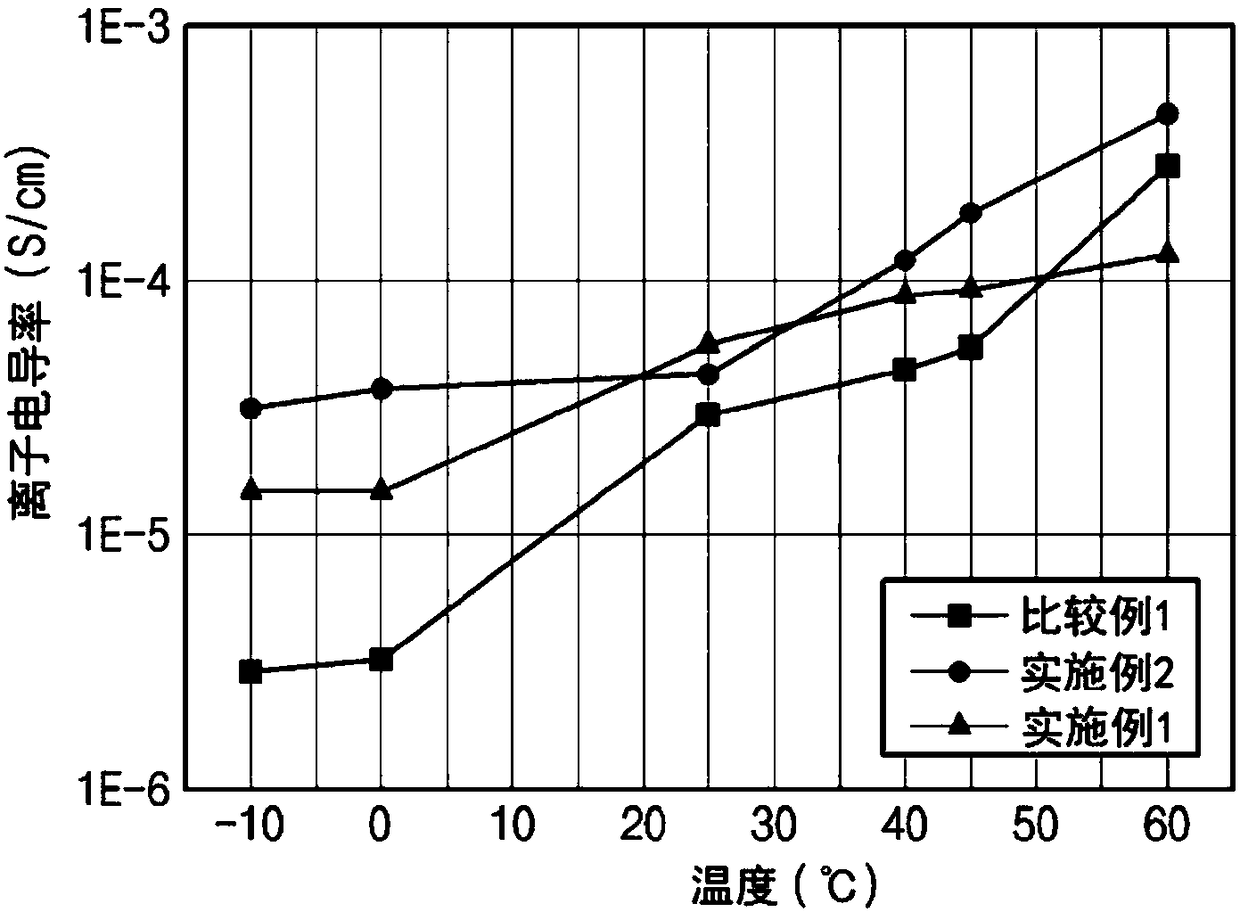

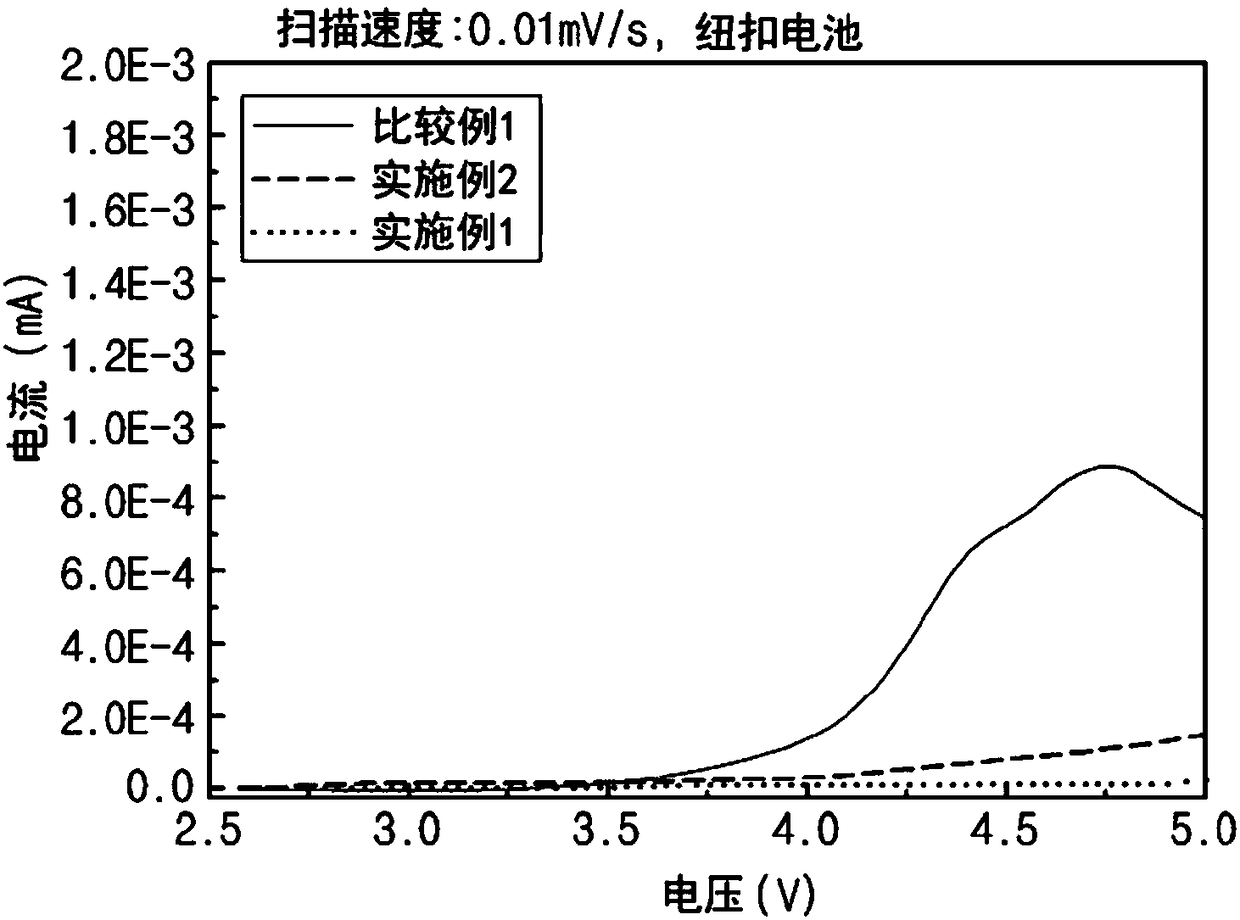

Embodiment 1

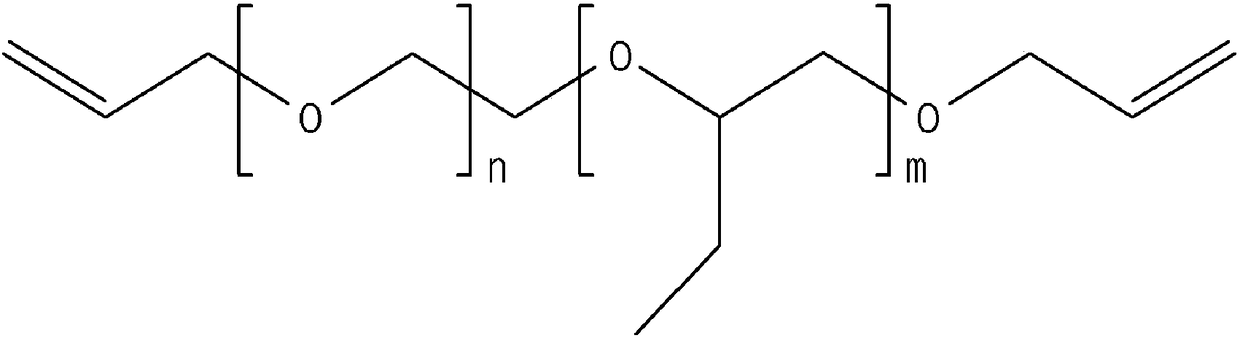

[0116] 35 g of a polymer represented by Formula 1 with a weight average molecular weight of 100,000 (the molar ratio of n:m is 20:1), 55 g of lithium lanthanum zirconium oxide (Li 7 La 3 Zr 2 o 12 ; LLZO), and 10 g lithium salt (LiTFSI) were dissolved in acetonitrile. Thereto was added 0.7 g of methyl benzoylformate as a polymerization initiator to prepare a composition for a polymer electrolyte having a solid content of 40%.

[0117] Subsequently, a membrane was coated with the composition for a polymer electrolyte, and then the composition was vaporized at 40° C. to form a membrane, and then irradiated with ultraviolet rays to prepare a solid polymer electrolyte membrane having a thickness of 30 μm.

Embodiment 2

[0119] Prepare a solid polymer electrolyte membrane in the same manner as in Example 1, except that instead of LLZO, lithium germanium aluminum phosphate (Li 1.3 al 0.3 Ge 1.7 (PO 4 ) 3 ; LAGP) for mixing.

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical conductivity | aaaaa | aaaaa |

| electrical conductivity | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com