Sheep bone soup base, preparation method thereof and sheep bone soup prepared by sheep bone soup base

A production method, the technology of mutton bone soup, which is applied in the field of food processing, can solve the problems of deterioration of nutritional components, unsatisfactory, insufficient release of nutrient components of mutton bone soup, etc., and achieve the effect of pure taste and convenient and quick consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

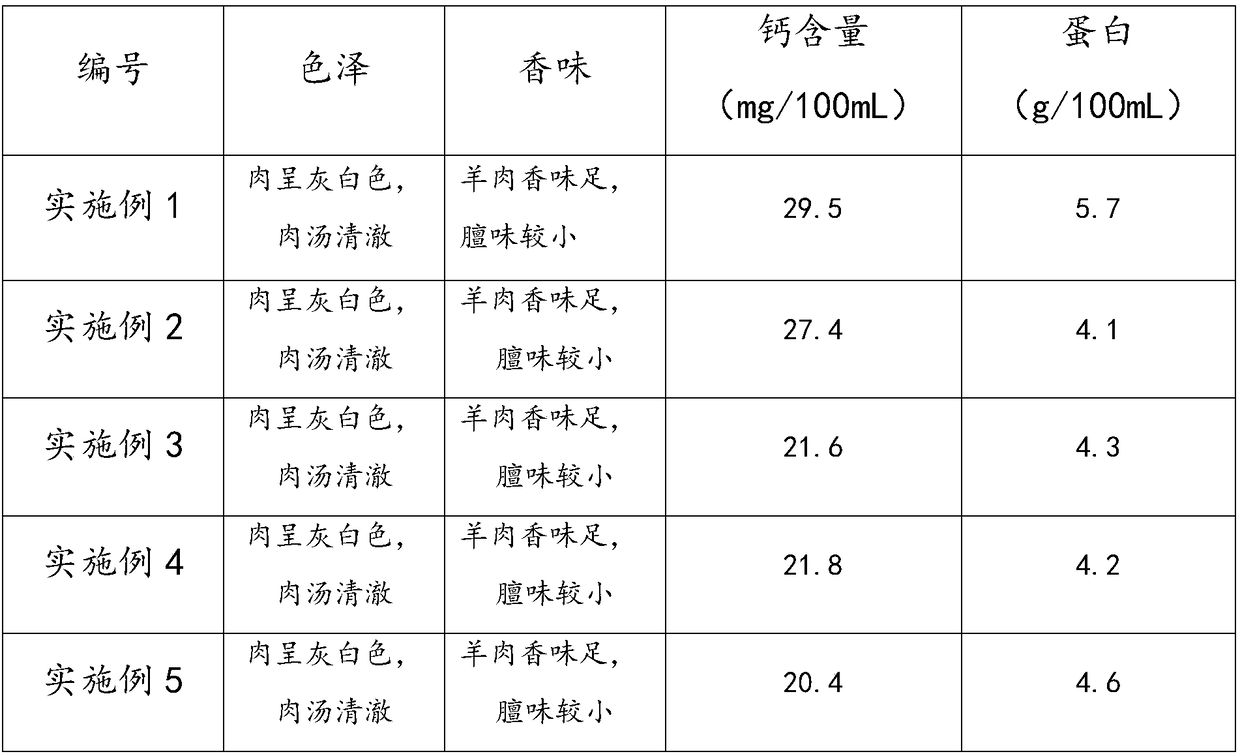

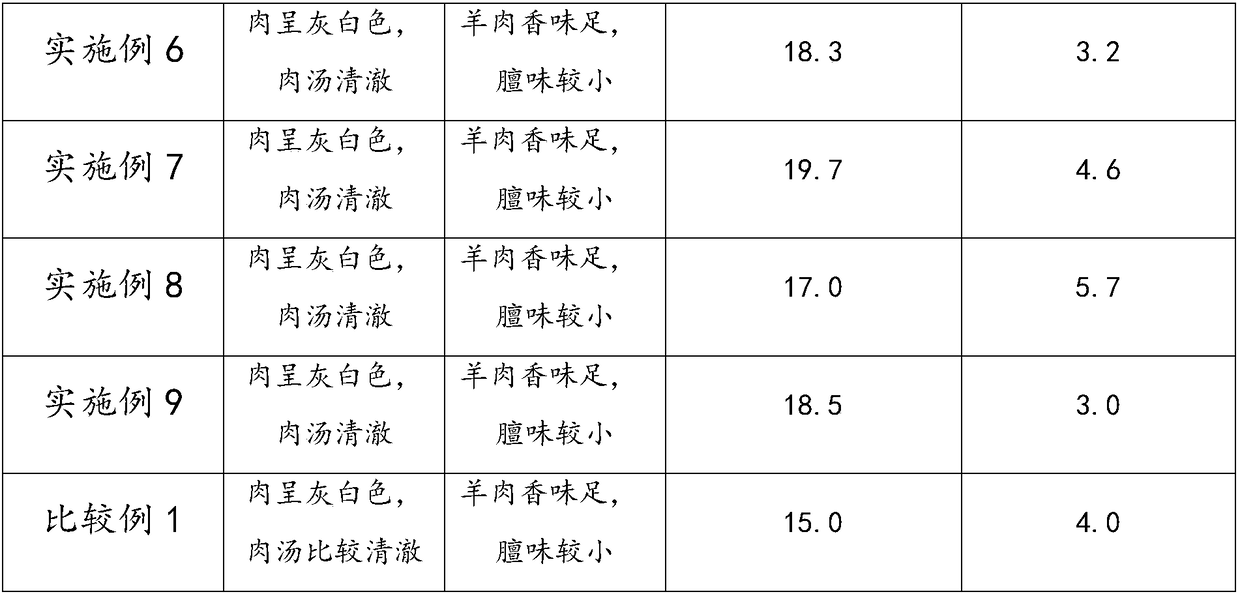

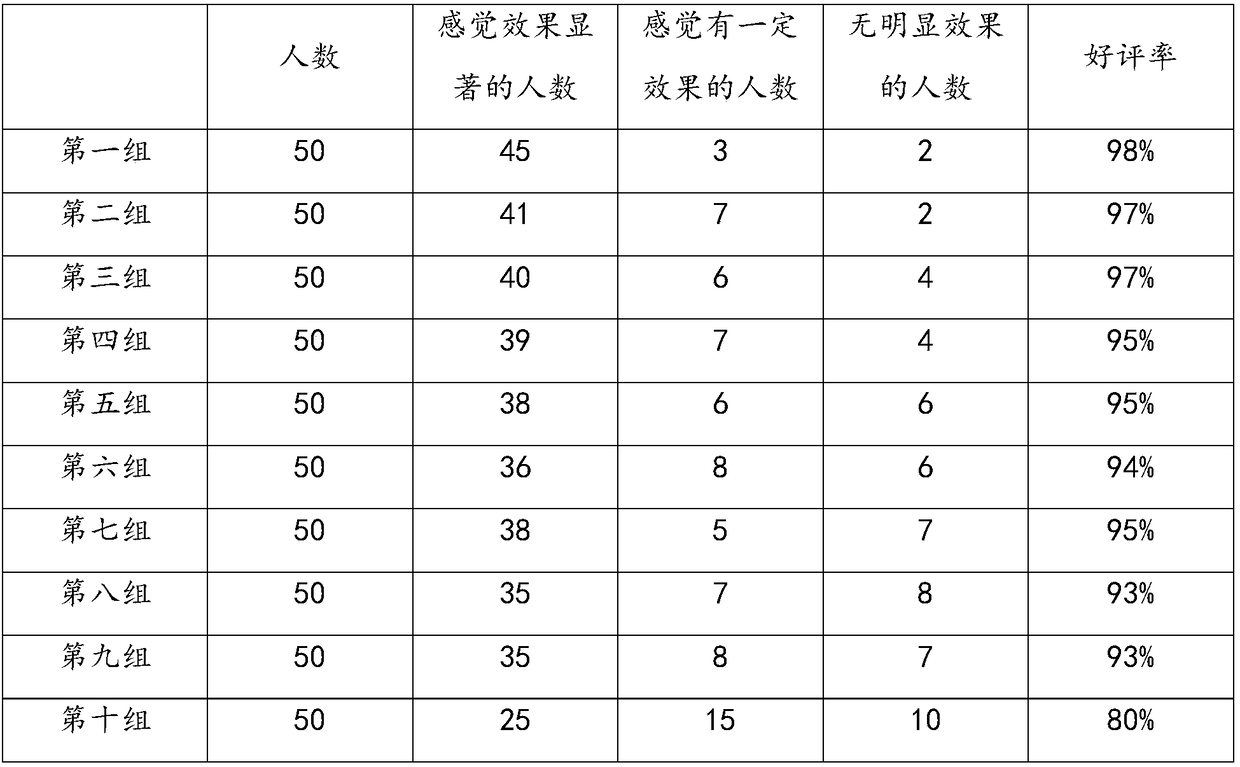

Examples

Embodiment 1

[0044] The preparation method of the mutton bone stock of the present embodiment comprises the steps:

[0045] (a) Raw material selection: select lamb spines and lamb bones without meat from grazing on the grasslands of Inner Mongolia.

[0046] (b) Shaping: Cut the lamb spine horizontally into 3 cm long spine pieces, remove the meatless parts on both sides of the hip bone; cut the lamb bone without meat horizontally in the middle and divide it into two halves.

[0047] (c) Slowing down: place the reshaped lamb spine and lamb bone without meat separately, and place them in a low temperature environment of 0-4°C for 20 hours, so that the lamb spine and lamb bone without meat are completely melted Finally, put the lamb backbone and lamb bone without meat in normal temperature water at 25°C for 20 minutes, and then wash them with normal temperature water for 2-3 times.

[0048] (d) Pre-cooking: first put the lamb spine into the pot under cold water, and add water to cover the lam...

Embodiment 2

[0054] The preparation method of the mutton bone stock of the present embodiment comprises the steps:

[0055] (a) Raw material selection: select lamb spines and lamb bones without meat from grazing on the grasslands of Inner Mongolia.

[0056] (b) Shaping: Cut the lamb spine horizontally into 2 cm long spine pieces, remove the meatless parts on both sides of the hip bone; cut the lamb bone without meat horizontally in the middle and divide it into two halves.

[0057] (c) Slowing down: place the reshaped lamb spine and lamb bone without meat separately, and place them in a low temperature environment of 0-4°C for 15 hours, so that the lamb spine and lamb bone without meat are completely melted Finally, place the lamb backbone and the lamb bone without meat in water at room temperature at 25°C for 10 minutes, and then wash them with water at room temperature for 2-3 times.

[0058] (d) Pre-cooking: first put the lamb spine in the pot under cold water, and add water to cover t...

Embodiment 3

[0064] The preparation method of the mutton bone stock of the present embodiment comprises the steps:

[0065] (a) Raw material selection: select lamb spines and lamb bones without meat from grazing on the grasslands of Inner Mongolia.

[0066] (b) Shaping: Cut the lamb spine horizontally into 4 cm long spine pieces, remove the meatless parts on both sides of the hip bone; cut the lamb bone without meat horizontally in the middle and divide it into two halves.

[0067] (c) Tempering: place the reshaped lamb spine and lamb bone without meat separately, and place them in a low temperature environment of 0-4°C for 25 hours, so that the lamb spine and lamb bone without meat are completely melted Finally, put the lamb spine and lamb bone without meat in water at room temperature at 25°C for 30 minutes, and then wash them with water at room temperature for 2-3 times.

[0068] (d) Pre-cooking: first put the lamb spine in the pot under cold water, and add water to cover the lamb spin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com