Method and system for treating high-salinity and poor-biodegradability percolate

A treatment method and leachate technology are applied in the field of leachate treatment methods and systems with high salinity and poor biodegradability, which can solve the problems of vicious circle, accumulation of salinity and COD, and low yield of produced water, and achieve stable, efficient and stable operation. , to avoid accumulation, to avoid the effect of scaling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

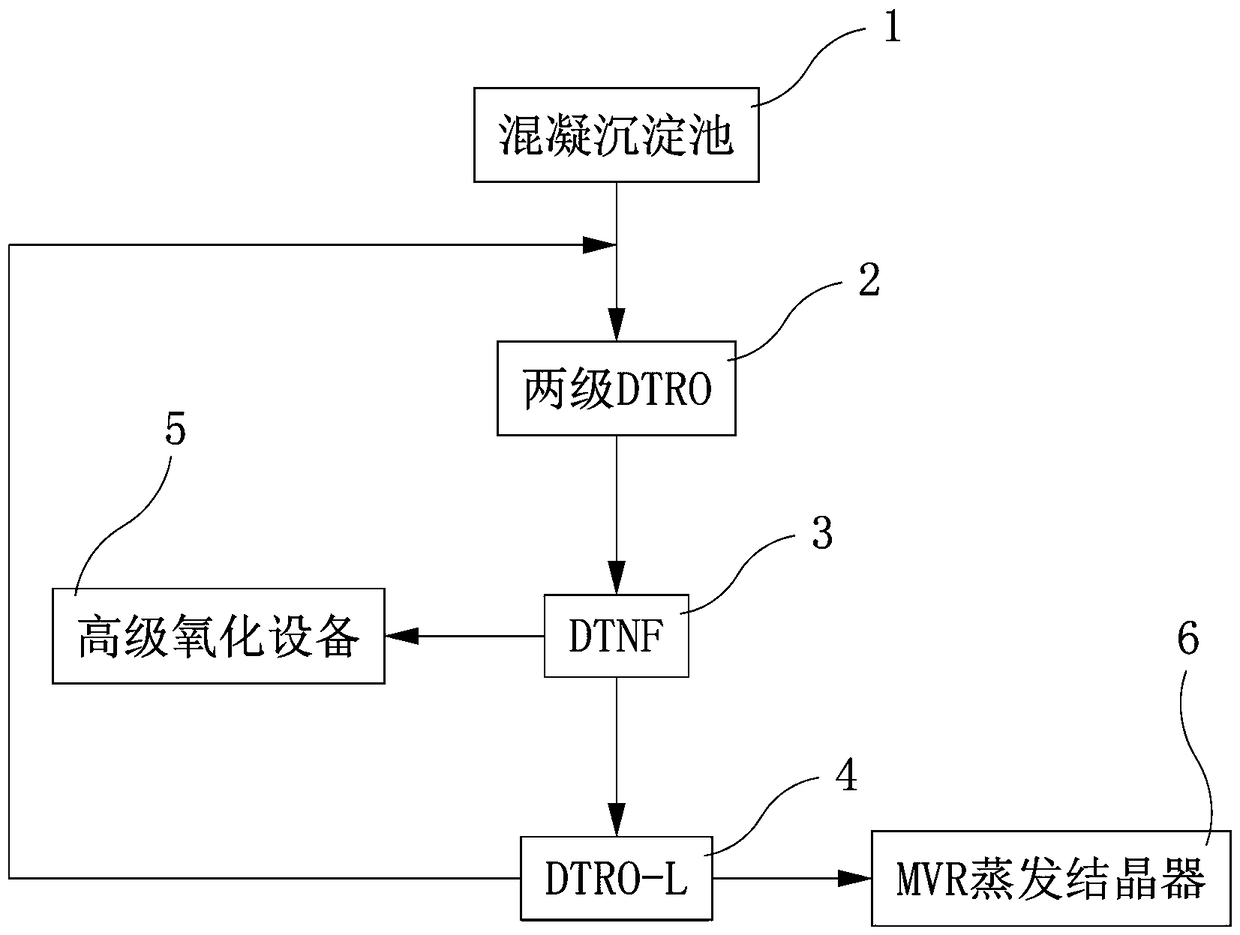

[0031] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

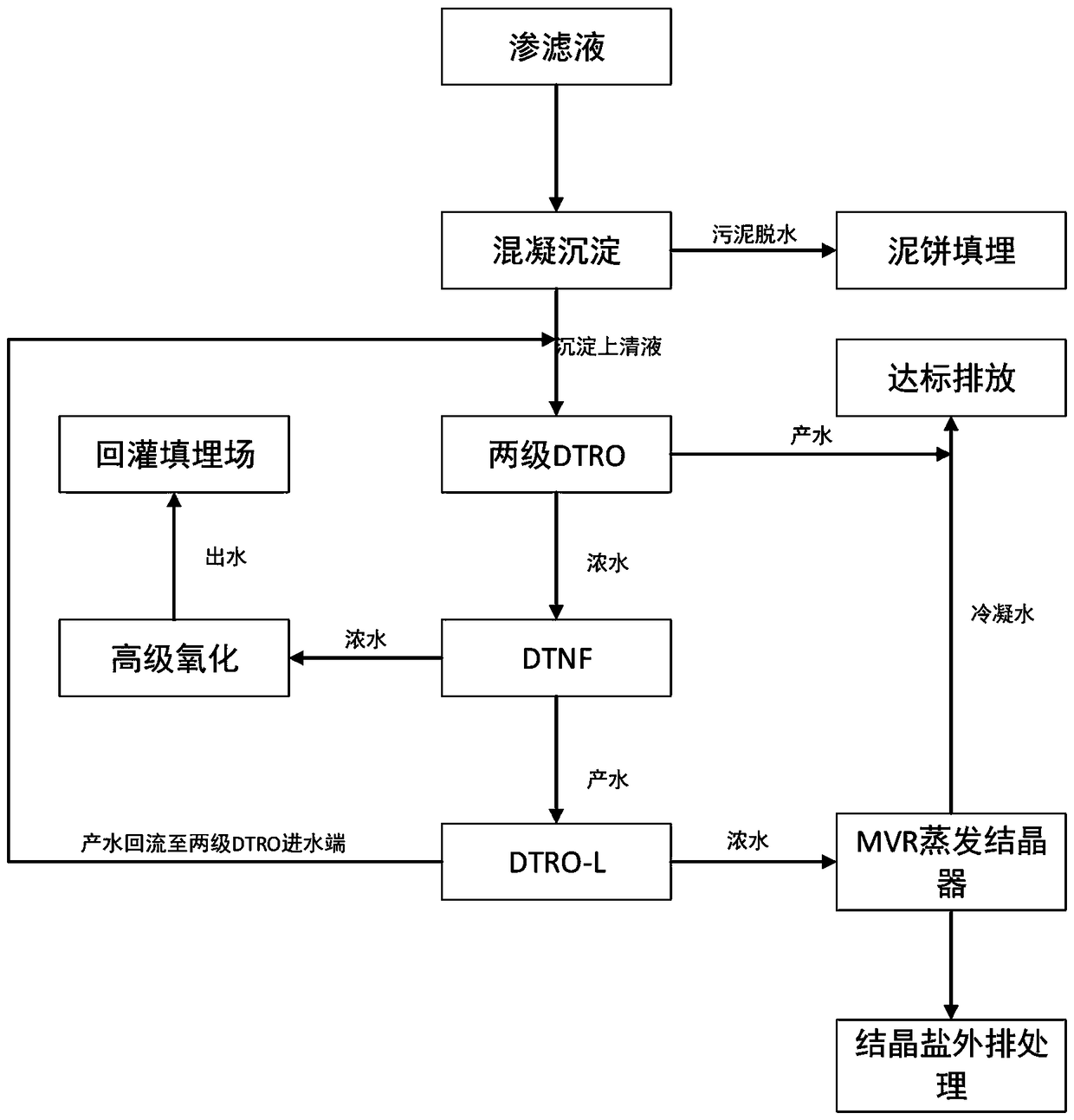

[0032] see figure 1 As mentioned above, a leachate treatment method for high-salinity leachate with poor biodegradability disclosed in this embodiment includes the following steps:

[0033] (1) First pump the leachate into the coagulation sedimentation tank. The TDS of the leachate that can be treated by the present invention can reach more than 30000mg / L, the COD is 20000~30000mg / L, the ammonia nitrogen content is more than 2000mg / L, and the biodegradability is poor; this implementation Example treated leachate COD (chemical oxygen demand), ammonia nitrogen, TDS (total dissolved solids) and SS (suspended solids) are 20900mg / L, 2896mg / L, 37870mg / L and 880mg / L respectively, and the water inflow is 500t / d. PAC (polyaluminum chloride) with an dosage of 300-500ppm is used as a coagulant. In this example, 500ppm of PAC is added according to the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com