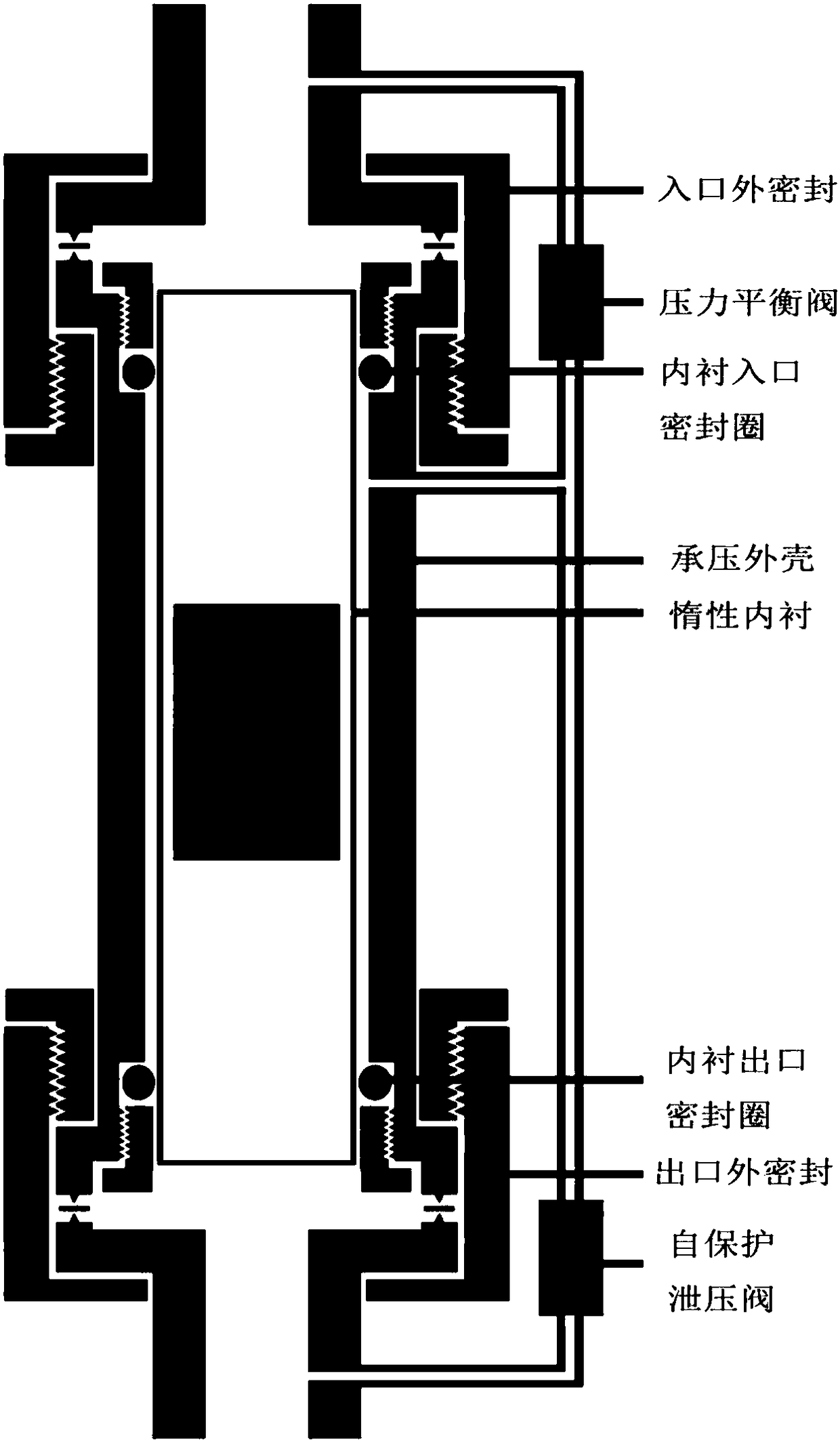

Reactor capable of self-balancing pressures inside and outside lining pipe, and use method thereof

A technology of internal and external pressure and reactor, which is used in the methods of chemically changing substances by atmospheric pressure, chemical instruments and methods, pressure vessels/vacuum vessels, etc. It can solve the problem of uneven mixing of diluent gas, reduce data repeatability, and product detection. The problem of increasing errors and affecting the results of product analysis can achieve the effect of low cost, easy installation and high safety.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] Empty tube experiment of direct conversion of synthesis gas: open the upper or lower end of the reaction tube, take out the inert liner, after cleaning, install the inert liner directly inside the pressure-bearing shell without filling the catalyst, and seal the upper and lower ends of the pressure-bearing shell through the sealing ring , seal the upper end of the reaction tube, connect the upper and lower ends of the pressure-bearing shell with the air inlet and outlet pipes respectively; install a back pressure valve behind the air outlet, and connect the outlet end of the self-protection pressure relief valve between the air outlet and the back pressure valve. Install an open-bore tube furnace in the equal diameter area in the middle of the pressure shell, and ensure that the constant temperature section of the tube furnace corresponds to the inert lining catalyst loading area.

[0028] After sealing, use raw material gas (5% Ar (internal standard), CO: 47.5%, H2: 47....

Embodiment 2

[0030] Example 2: Catalyst reaction evaluation for direct conversion of synthesis gas to olefins:

[0031] Open the upper or lower end of the reaction tube, take out the inert liner, after cleaning, first fill with 0.3cm high quartz wool, then fill with catalyst: ZnCrAl+SAPO34, 280mg, and finally fill with 0.3cm high quartz wool, install the inert liner on the bearing Inside the pressure shell, the upper and lower ends are sealed between the sealing ring and the pressure-bearing shell, the upper and lower ends of the reaction tube are sealed, and the upper and lower ends of the pressure-bearing shell are respectively connected to the air inlet and outlet pipes; a back pressure valve is installed behind the gas outlet, and the self-protection pressure release The outlet end of the valve is connected between the air outlet and the back pressure valve. Install an open-bore tube furnace in the equal diameter area in the middle of the pressure shell, and ensure that the constant te...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com