Porous carbon material loaded with ruthenium nanoparticles, and preparation method and application thereof

A technology of porous carbon materials and nanoparticles, applied in carbon preparation/purification, chemical instruments and methods, catalyst activation/preparation, etc., can solve the problems of catalyst agglomeration, slow hydrogen release rate, catalyst instability, etc., and achieve low cost Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0040] A preparation method of a porous carbon material loaded with ruthenium nanoparticles, the specific steps are as follows:

[0041] Step 1) Prepare the nitrogen-containing precursor, add 4 g of glucose and 2 g of semicarbazide hydrochloride, add 60 ml of deionized water and stir to dissolve the deionized water, then put it in the reaction kettle for reaction at 180 ° C, and after the reaction, the product Filtration, washing, and drying to obtain the precursor;

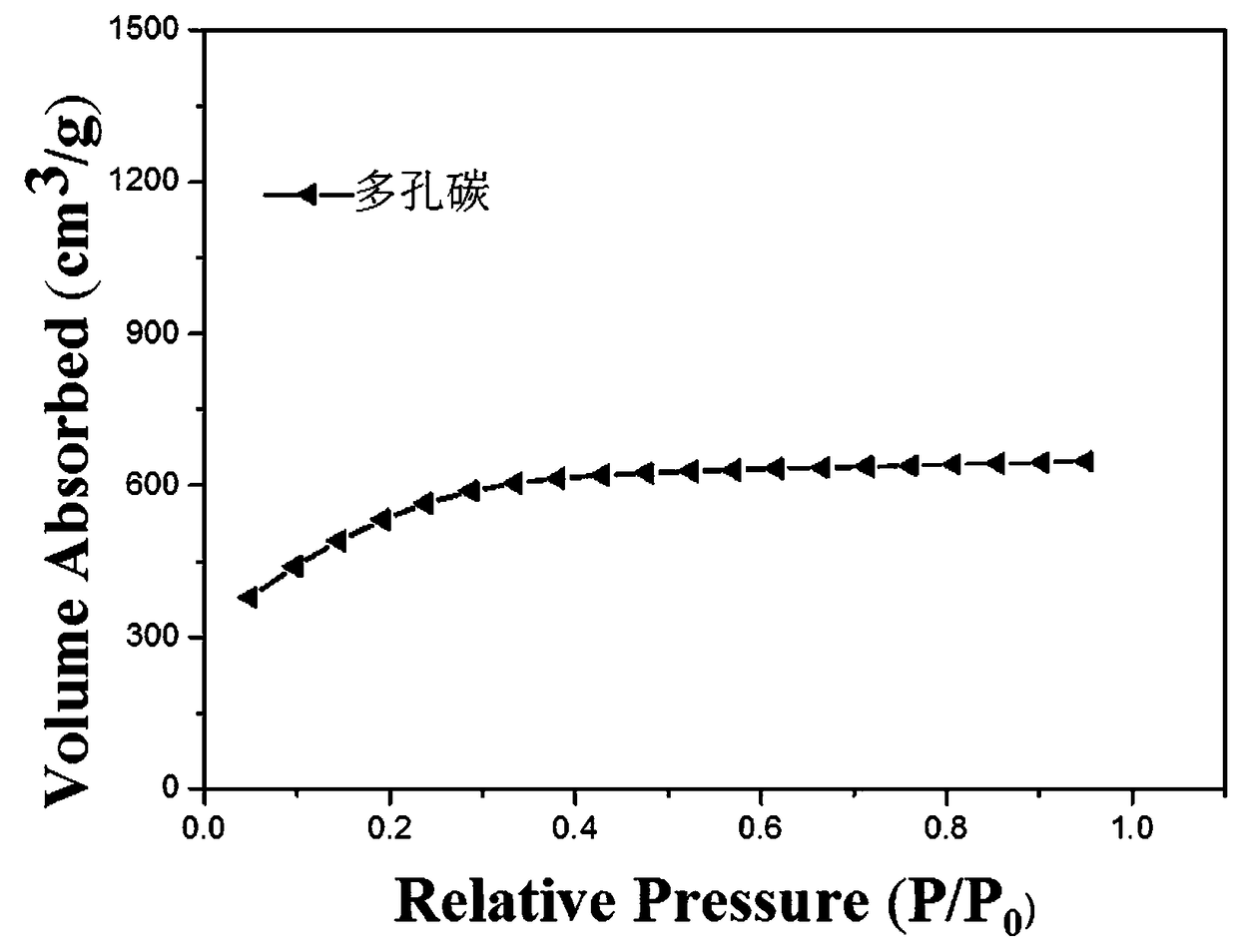

[0042] Step 2) To prepare a porous structure carbon material, mix the precursor of step 1) and potassium hydroxide according to the mass ratio of 1:2, soak in deionized water, after drying, put it into a tube furnace, under the protection of nitrogen, Calcined at 700°C for 2 h to obtain carbon materials, after cooling down, the calcined carbon materials were taken out for grinding, after grinding, soaked in hydrochloric acid solution with a concentration of 1 mol / L, washed, filtered, dried, Grinding to obtain a ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com