Florfenicol powder crusher

A florfenicol powder and pulverizer technology, which is applied in the direction of solid separation, sieve, grid, etc., can solve the problems of unfavorable processing, uneven size, and inability to crush small granular materials, so as to avoid accumulation and reduce effect of influence

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

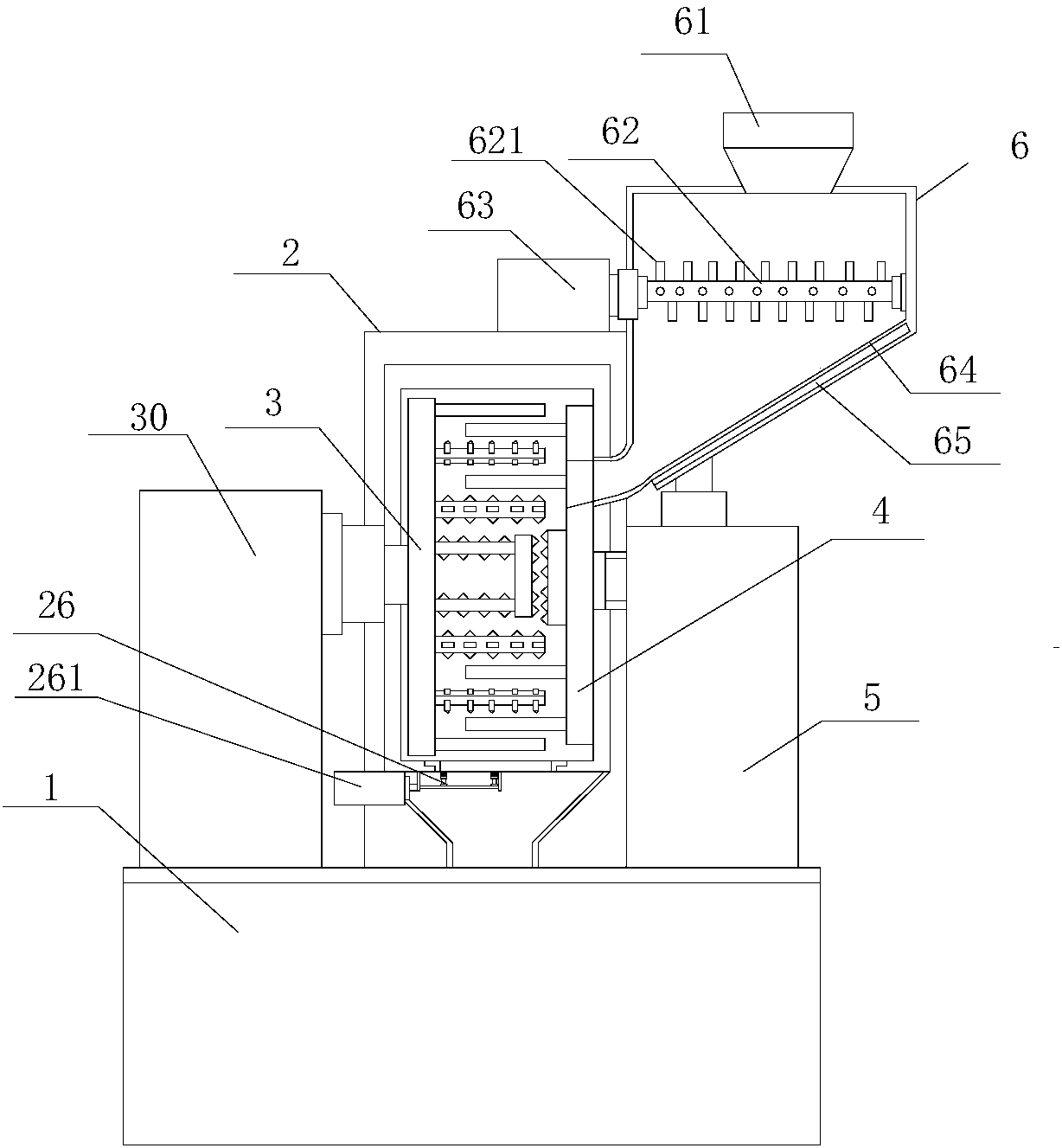

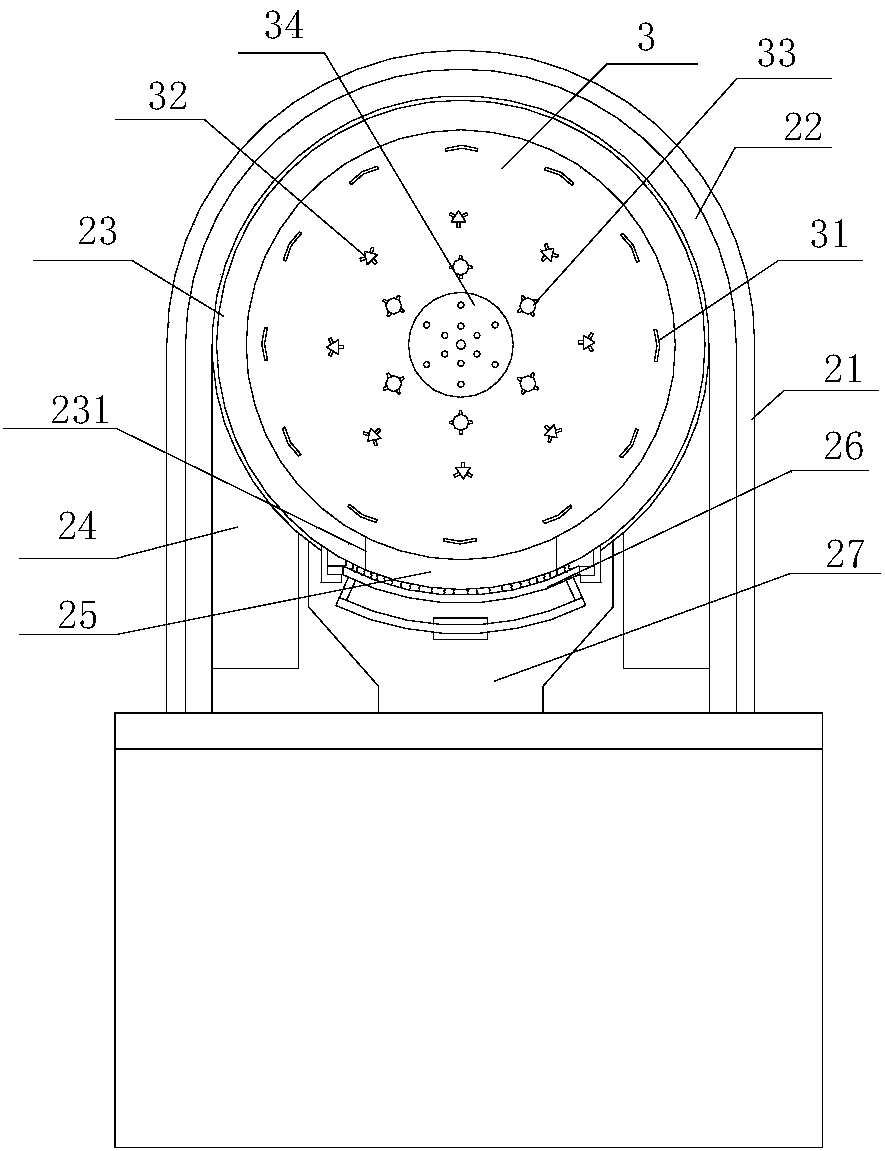

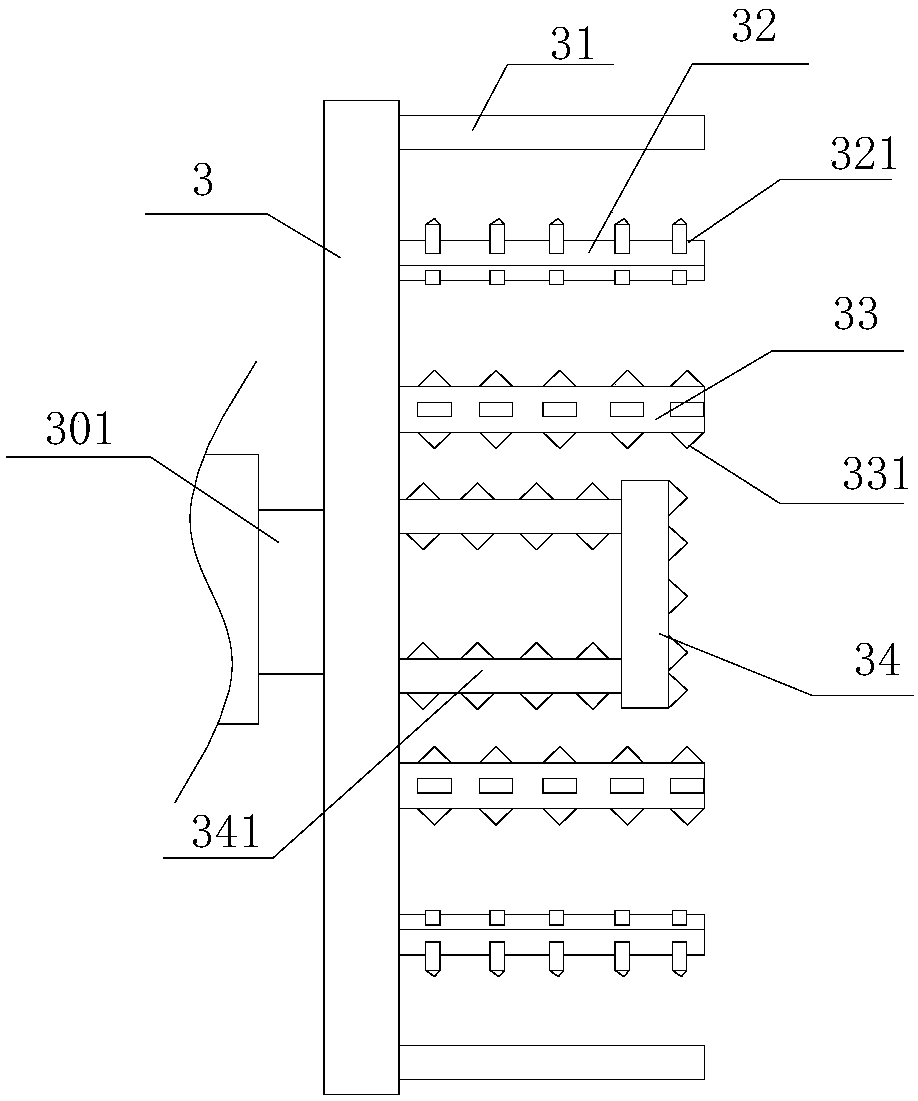

[0020] refer to Figure 1 to Figure 8 A florfenicol pulverizer of the present invention comprises a frame 1, a crushing chamber 2, a moving cutter mechanism 3, a static cutter mechanism 4, a water-cooling circulation system 5 and a feeding box 6, and the frame 1 is provided with There is a crushing chamber 2, the upper material box 6 is installed on the side wall of the crushing chamber 2, a feeding hopper 61 is arranged above the upper material box 6, and a first crushing shaft 62 is arranged below the feeding hopper 61 , the outer circumference of the first crushing shaft 62 is evenly provided with several first crushing rods 621, the movable cutter mechanism 3 and the static cutter mechanism 4 are installed in the crushing chamber 2, and one side of the crushing chamber 2 A power box 30 is provided, and the power box 30 controls the rotation of the movable cutterhead mechanism 3 through the drive shaft 301. The movable cutterhead mechanism 3 cooperates with the static cutte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com