Diamond grinding head and preparation technology thereof

A preparation process and diamond technology, applied in the direction of manufacturing tools, metal processing equipment, grinding/polishing equipment, etc., can solve the problems of debris clogging, processing efficiency and noise, reduce wear and working noise, reduce use cost, combine Lego effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

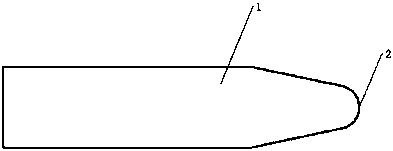

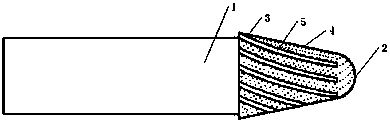

[0022] Such as figure 2 As shown, a diamond grinding head includes a connecting rod part 1, a grinding head base body 2, a brazing material 3, diamond abrasive grains 4 and a spiral groove 5. The grinding head base 2 of the diamond grinding head is directly connected with the connecting rod part 1 as a whole. The surface of the base body 2 of the grinding head is fixed with diamond abrasive grains 4 by brazing; the diamond grinding layer on the surface of the base body 2 of the grinding head is provided with multiple spiral grooves 5 by laser. The base body 2 of the grinding head is conical.

[0023] The preparation process is as follows: weigh 100g of thermoplastic resin adhesive and ethanol diluent according to the mass ratio of 5:1, mix well, apply the mixture evenly on the surface of grinding head base 2, and let it stand for 15 minutes. Roll the treated grinding head substrate 2 in the nickel-based brazing material granules to form the nickel-based brazing material 3 b...

Embodiment 2

[0025] Such as figure 2 As shown, a diamond grinding head includes a connecting rod part 1, a grinding head base body 2, a brazing material 3, diamond abrasive grains 4 and a spiral groove 5. The grinding head base 2 of the diamond grinding head is directly connected with the connecting rod part 1 as a whole. The surface of the base body 2 of the grinding head is fixed with diamond abrasive grains 4 by brazing; the diamond grinding layer on the surface of the base body 2 of the grinding head is provided with multiple spiral grooves 5 by laser. The base body 2 of the grinding head is conical.

[0026] The preparation process is as follows: weigh 100 g of thermoplastic resin adhesive and ethanol diluent in a mass ratio of 4:1, mix well, apply the mixture evenly on the surface of grinding head base 2, and let it stand for 20 minutes. Roll the treated grinding head substrate 2 in the copper-based brazing material granules to form the copper-based brazing material 3-base layer; ...

Embodiment 3

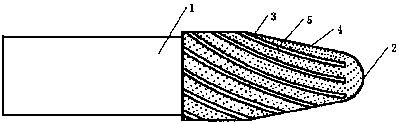

[0028] Such as image 3 As shown, a diamond grinding head includes a connecting rod part 1, a grinding head base body 2, a brazing material 3, diamond abrasive grains 4 and a spiral groove 5. The grinding head base 2 of the diamond grinding head is directly connected with the connecting rod part 1 as a whole. The surface of the base body 2 of the grinding head is fixed with diamond abrasive grains 4 by brazing; the diamond grinding layer on the surface of the base body 2 of the grinding head is provided with multiple spiral grooves 5 by laser. The base body 2 of the grinding head is cylindrical and conical, and can be drilled and repaired.

[0029] The preparation process is as follows: weigh 100g of thermoplastic resin adhesive and ethylene glycol diluent according to the mass ratio of 6:1, mix well, apply the mixed solution evenly on the surface of the grinding head base 2, and let it stand for 10 minutes. Roll the treated grinding head substrate 2 in the silver-based braz...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com