A kind of bioactive granular pavement maintenance material and preparation method thereof

A bioactive particle technology, applied in the field of bioactive particle road maintenance materials and their preparation, can solve the problems of exhaust pollution, catalyst poisoning, automobile exhaust pollution, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0064] The present invention provides a preparation method of the biologically active granular pavement maintenance material described in the above technical solution, comprising the following steps:

[0065] a) mixing mineral materials and fillers to obtain a first mixture;

[0066] mixing the first mixture with itaconic acid, fibers, additives and water to obtain a second mixture;

[0067] mixing the mixture of bioactive particles and coupling agent with polyethylene glycol to obtain a third mixture;

[0068] b) mixing the second mixture with the third mixture, and then mixing with base asphalt and fatty alcohol polyoxyethylene ether penetrating agent to obtain a biologically active granular pavement maintenance material.

[0069] In the present invention, mineral materials and fillers are mixed to obtain the first mixture. The types of mineral materials and fillers are the same as those described in the above technical solution, and will not be repeated here. The mineral...

Embodiment 1

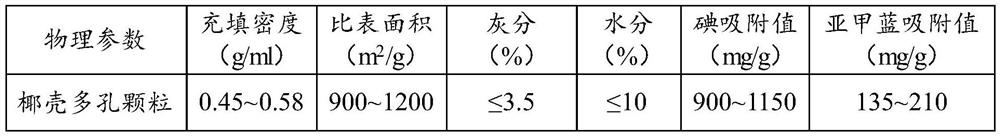

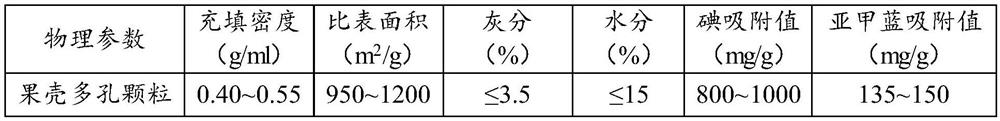

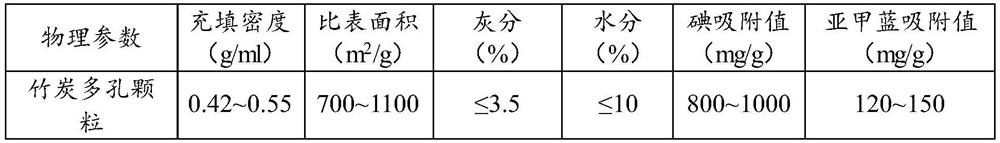

[0076] 100 parts of basalt mineral material, 8 parts of SBR modified emulsified asphalt, 3.5 parts of 20 mesh coconut shell porous particles, 0.5 part of itaconic acid, 1 part of NXT101 titanate coupling agent, 0.5 part of PEG200 polyethylene glycol, fatty alcohol poly 0.2 parts of oxyethylene ether JFC-1, 8 parts of water, 0.4 parts of polyester fiber, 1 part of cement, and 5 parts of limestone mineral powder;

[0077] First, use a square hole sieve larger than the target pore size to sieve the bioactive particles to keep the bioactive particles under the sieve, and then use a square hole sieve slightly smaller than the target pore size to sieve the bioactive particles on the sieve; After the sieved bioactive particles are washed with water, remove impurities, place them in a vacuum drying oven, and dry them for 24 hours in a constant temperature and humidity vacuum environment with a temperature of 45°C and a humidity of 80%.

[0078] Take the coupling agent and alcohols or ...

Embodiment 2

[0081] A biologically active granular pavement maintenance material, which is made by mixing the following raw materials in parts by weight: 100 parts of basalt mineral material, 11 parts of SBR modified emulsified asphalt, 6 parts of 20-mesh coconut shell porous particles, coating Conic acid 0.75 parts, NXT101 titanate coupling agent 1.5 parts, PEG200 polyethylene glycol 0.75 parts, fatty alcohol polyoxyethylene ether JFC-10.35 parts, water 10 parts, polyester fiber 0.6 parts, cement 2 parts, limestone ore Powder is 6.5 parts.

[0082] The treatment method of the bioactive granules in this embodiment and the preparation method of the bioactive granule pavement maintenance material are the same as in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com