A kind of bionic ternary ion-doped hydroxyapatite bioceramic powder material and its preparation method and application

A hydroxyapatite and ion doping technology, which is applied in biomedical materials and chemical fields, can solve the problems of complex material synthesis process, achieve simple operation, low cost, and promote the proliferation and differentiation of osteoblasts

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

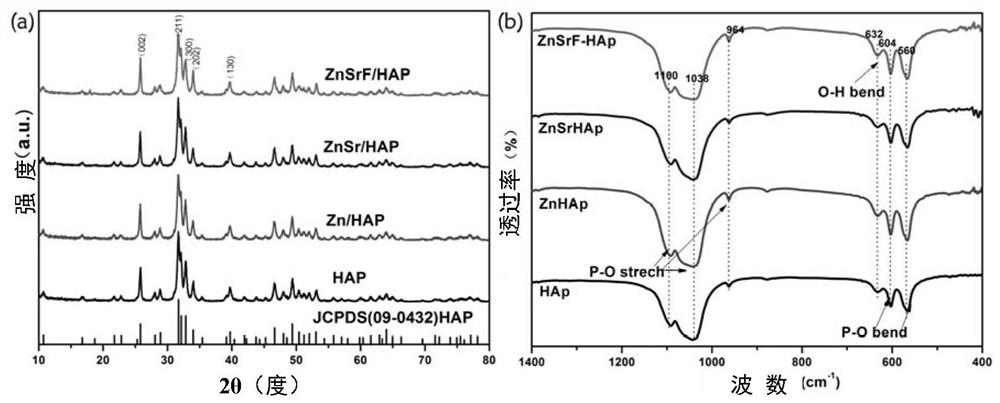

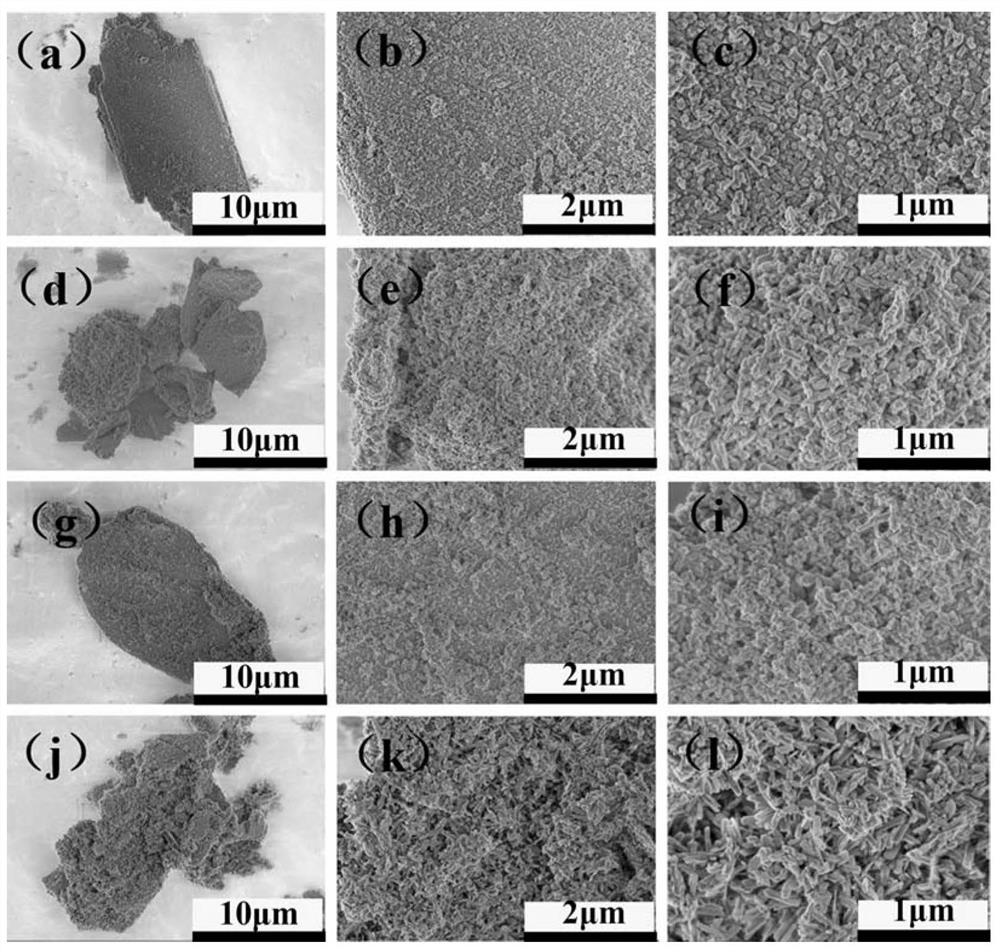

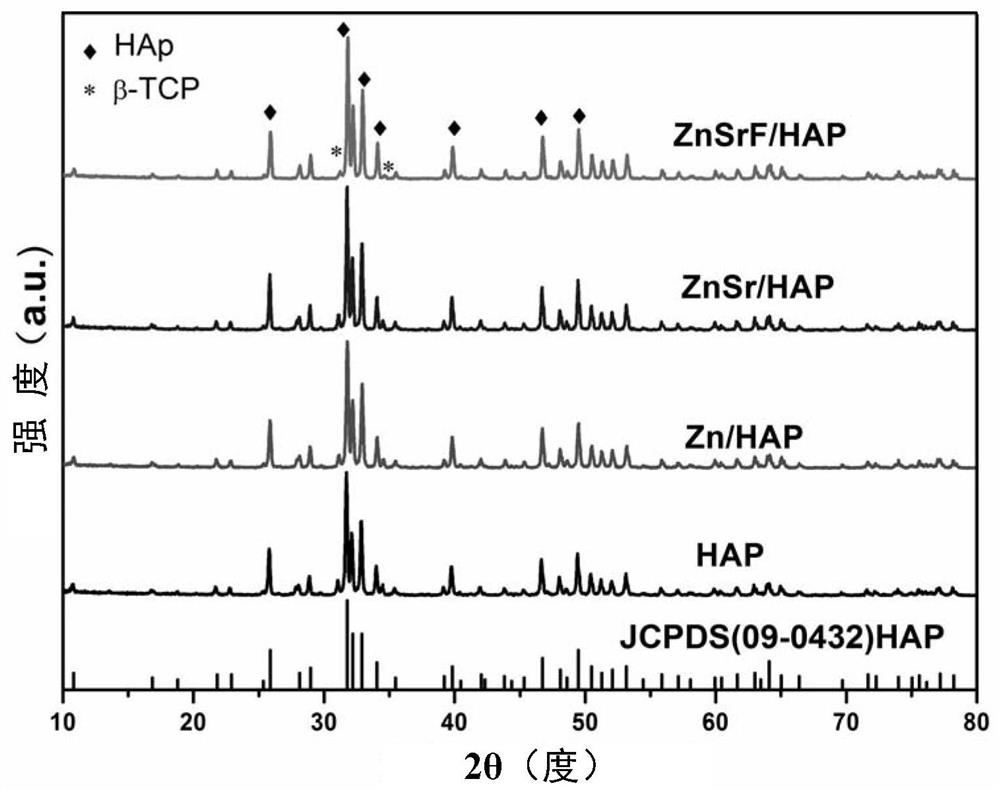

Embodiment 1

[0051] (1) according to the following chemical formula Ca 10 (PO 4 ) 6 (OH) 2 The stoichiometric ratio of (HAP) accurately weighed 3.7810g Ca (H 2 PO 4 ) 2 ·H 2 O, 2.5932g Ca(OH) 2 , add water and stir evenly;

[0052] (2) Transfer the reaction solution into a polytetrafluoroethylene container. Use a stainless steel container to fix it in a homogeneous reactor with a rotation speed of 15 rpm and a reaction condition of 150°C for 24 hours;

[0053] (3) After the reaction is completed, the wet powder is obtained by suction filtration, and dried to obtain the hydroxyapatite powder Ca 10 (PO 4 ) 6 (OH) 2 ;

[0054] (4) Using a mold with a diameter of 13 mm, press 0.2 g of powder under a pressure of 10 MPa for 1 minute, and sinter at 1000 ° C for three hours to prepare a hydroxyapatite bioceramic bulk material.

Embodiment 2

[0056] (1) according to the following chemical formula Ca 9.995 Zn 0.005 (PO 4 ) 6 (OH) 2 The stoichiometric ratio of (Zn / HAP) accurately weighed 3.7810g Ca(H 2 PO 4 ) 2 ·H 2 O, 2.5915g Ca(OH) 2 , 0.0074g Zn(H 2 PO 4 ) 2 2H 2 O (g) add water and stir well.

[0057] (2) Transfer the reaction solution into a polytetrafluoroethylene container. Use a stainless steel container to fix it in a homogeneous reactor with a rotation speed of 15 rpm and a reaction condition of 150°C for 24 hours;

[0058] (3) After the reaction is completed, the wet powder is obtained by suction filtration, and dried to obtain Zn-doped hydroxyapatite powder Ca 9.995 Zn 0.005 (PO 4 ) 6 (OH) 2 (Zn / HAP);

[0059] (4) Using a mold with a diameter of 13 mm, press 0.2 g of powder at a pressure of 10 MPa for 1 minute, and sinter at 1000 ° C for three hours to prepare a Zn ion-doped hydroxyapatite bioceramic bulk material.

Embodiment 3

[0061] (1) according to the following chemical formula Ca 9.989 Zn 0.005 Sr 0.006 (PO 4 ) 6 (OH) 2 The stoichiometric ratio of (ZnSr / HAP) accurately weighed 3.7810g Ca(H 2 PO 4 ) 2 ·H 2 O, 2.5893g Ca(OH) 2 , 0.0074g Zn(H 2 PO 4 ) 2 2H 2 O(g), 0.0080gSr(OH) 2 ·8H 2 O, add water and stir evenly;

[0062](2) Transfer the reaction solution into a polytetrafluoroethylene container. Use a stainless steel container to fix it in a homogeneous reactor with a rotation speed of 15 rpm and a reaction condition of 150°C for 24 hours;

[0063] (3) After the reaction is completed, the wet powder is obtained by suction filtration, and dried to obtain ZnSr / Ca 9.989 Zn 0.005 Sr 0.006 (PO 4 ) 6 (OH) 2 ;

[0064] (4) Use a mold with a diameter of 13mm to hold 0.2g of powder at a pressure of 10Mpa for 1 minute, and sinter at a temperature of 1000°C for three hours to make Zn ion and Sr ion binary doped doped hydroxyapatite Bioceramic bulk materials.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com