Preparation method of multi-component nano-crystal metal boride

A metal boride, nanocrystalline technology, applied in the field of materials, to achieve the effect of simple crystal structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

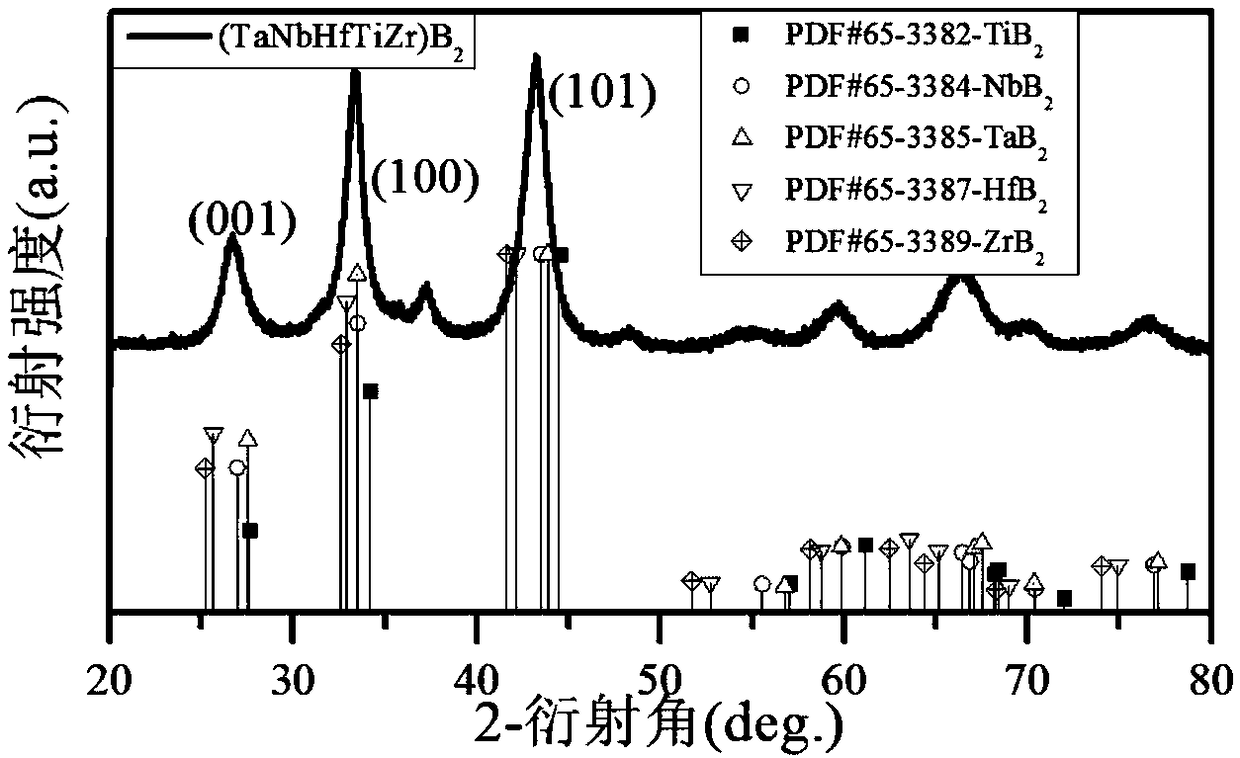

[0029] Prepare the powder according to the ratio of Ti: Zr: Ta: Hf: Nb: B = 0.2:0.2:0.2:0.2:0.2:2, mix the powder evenly in the glove box, put it in the WC ball mill tank, press the ball: the material is Add WC balls at a ratio of 3:1, seal the ball mill tank, and install it in a high-energy ball mill (SPEX D.Prep 8000M). Every ball mill for 2 hours, pause for 15 minutes as a cycle, a total of 12 cycles, after mechanical grinding for 24 hours, Take out the powder in the glove box, fully soak it in n-hexane, take it out, and dry it in a drying oven at 80°C for 24 hours; put 1.5g of the powder into the BN mold, and use a six-sided top hydraulic press to match the powder in the BN mold. The powder is subjected to high temperature and high pressure treatment, the pressure is 59MPa, and the actual pressure on the powder is 5GPa; the heating device is turned on 100s after the overpressure is over, and after the temperature rises to 1500°C, the heat preservation and pressure holding a...

Embodiment example 2

[0035] Prepare the powder according to the ratio of Ti: Zr: Ta: Hf: Nb: B = 0.2:0.2:0.2:0.2:0.2:2, mix the powder evenly in the glove box, put it in a hard steel ball mill tank, press the ball The ratio is 3:1, put bearing steel balls with a diameter of 6mm, and seal the ball mill tank in a high-energy ball mill (SPEX D.Prep 8000M). Every ball mill for 2 hours, pause for 15 minutes as a cycle, a total of 10 cycles , after mechanical grinding for 20 hours, take out the powder in the glove box, fully soak the powder in n-hexane, take it out, and dry it in a drying oven at 80°C for 24 hours; put 2g of the powder into a BN mold, and use a six-sided top hydraulic press. The powder installed in the BN mold is subjected to high temperature and high pressure treatment, the pressure is 59MPa, the actual pressure on the powder is 5GPa, the heating device is turned on 100s after the end of the overpressure, and after the temperature is raised to 1000°C, the heat preservation and pressure ...

Embodiment 3

[0040] Prepare the powder according to the ratio of Ti:Zr:Ta:Hf:Nb:B=0.2:0.2:0.2:0.2:0.2:2, mix the powder evenly in the glove box, put it in the WC ball mill tank, and the ball-to-material ratio is 3 :1 ratio, add WC balls, seal the ball mill tank, install it in a high-energy ball mill (SPEX D.Prep 8000M), every ball mill for 2 hours, pause for 15 minutes as a cycle, a total of 8 cycles, after mechanical grinding for 16 hours, in the glove box Take out the powder, put the powder in n-hexane and fully soak it, take it out, and dry it in a drying oven at 80°C for 24 hours; put 1.5g of the powder into the BN mold, and use a six-sided top hydraulic press to dry the powder in the BN mold. High-temperature and high-pressure treatment, the pressure is 59MPa, and the actual pressure on the powder is 5GPa; 100s after the end of overpressure, the heating device is turned on, and the power is increased to 836W, corresponding to the sintering temperature of 800°C, heat preservation and pr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Size | aaaaa | aaaaa |

| Hardness value | aaaaa | aaaaa |

| Fracture toughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com