Light hard CoCrAlSiNi high-entropy alloy and preparation method thereof

A high-entropy alloy and hard technology, which is applied in the field of light hard CoCrAlSiNi high-entropy alloy and its preparation, can solve the problems of toxic waste, high raw material cost, complicated preparation process, etc., and achieves uniform organization, simple crystal structure and simple operation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

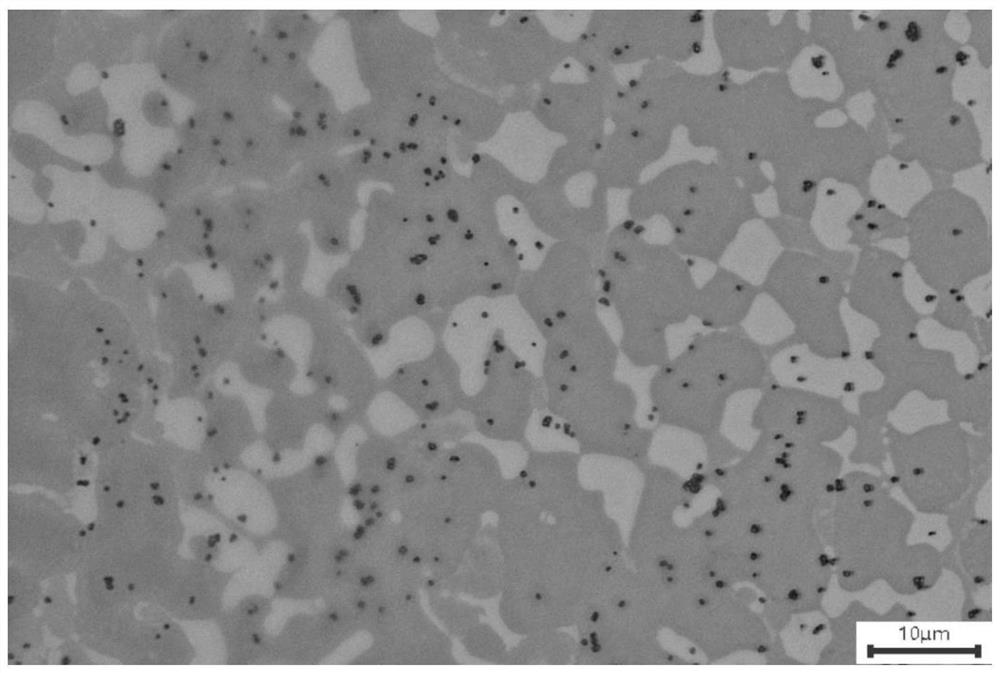

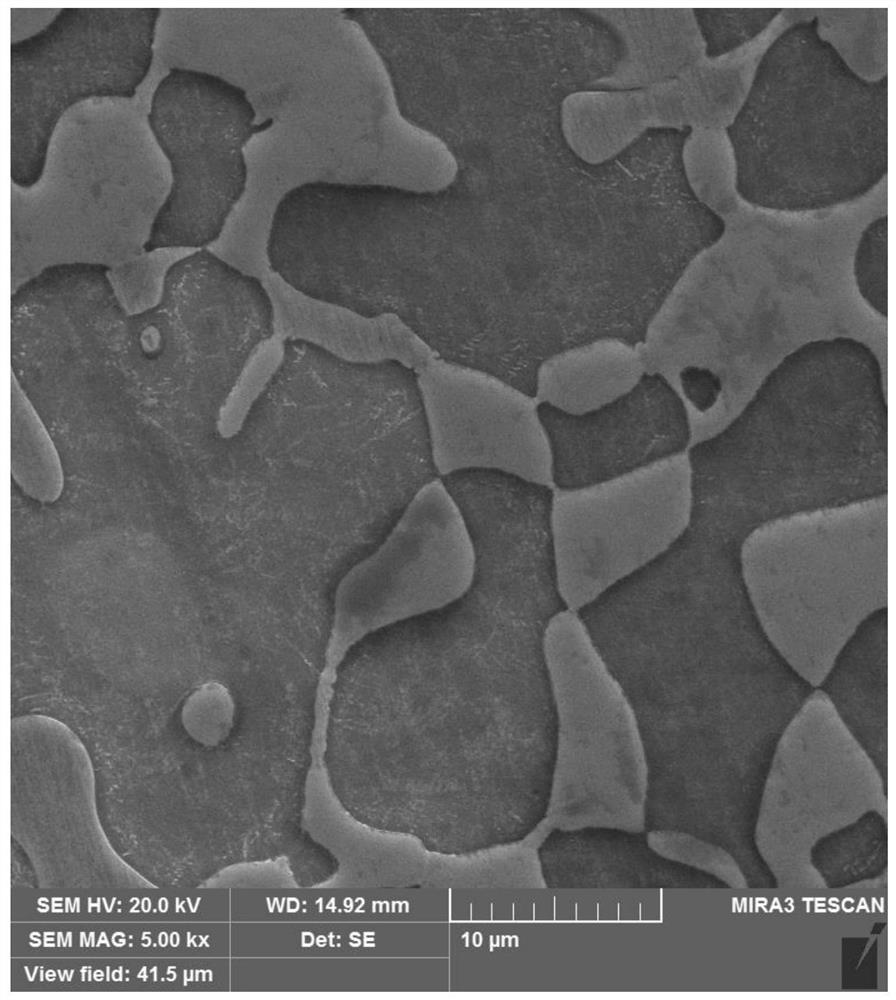

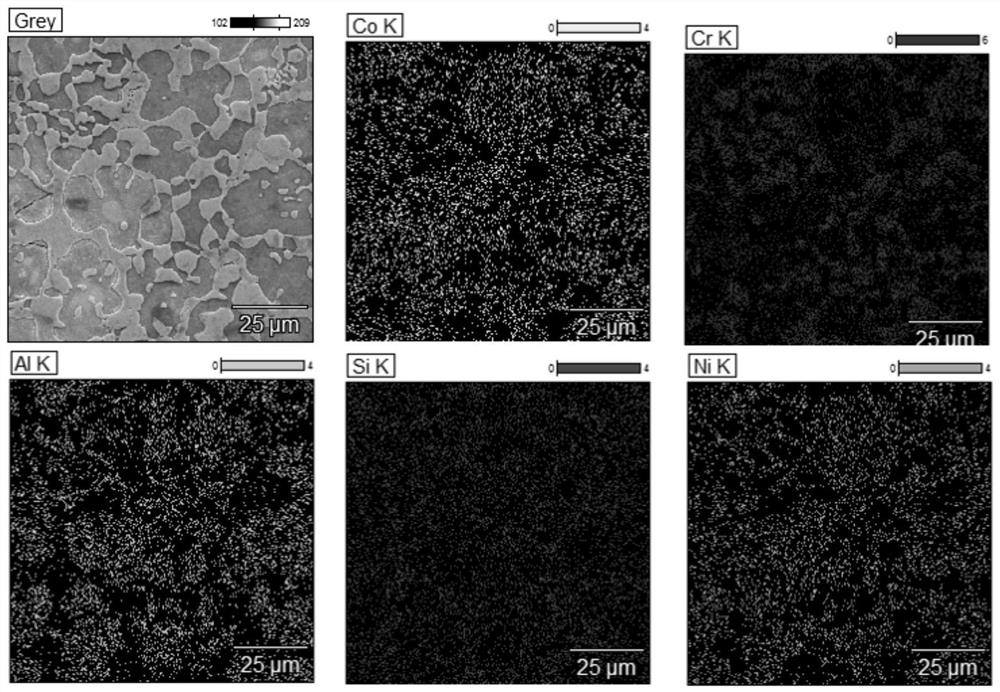

Image

Examples

Embodiment 1

[0047] This embodiment provides a light hard CocralSini high entropy alloy and its preparation method thereof, including the steps of:

[0048] (1) The target atom ratio CO: CR: Al: Si: Ni = 1: 1: 1: 1: 1, converted to Co raw materials, CR raw materials, Al raw materials, Si raw materials and NI The quality ratio of the raw material, weighing the purity of 99.99 wt.% Or more CO raw materials, Cr random, Al raw materials, Si raw materials and Ni raw materials, wherein the Si raw material is more than 10 wt.% On the basis of the target atomic ratio;

[0049] The symmetrical CO raw material, Cr random, Al raw material, Si feedstock is cleaned with Ni feedstock, first with deionized water as a cleaning solution, and then use 0.5 mol / L hydrochloric acid solution for pickling, then use no water Ethanol is washed with alcohol, and finally placed in a vacuum drying box for drying;

[0050] Open the humeral door of the self-consuming vacuum arc furnace, will be called the Si raw material...

Embodiment 2

[0054] This embodiment provides a light hard Cocralsini high entropy alloy and a preparation method thereof, based on the light hard Cocralsini high entropy alloy and its preparation method thereof, the difference is only: light hard Cocraalsini high entropy alloy Atom ratio CO: CR: Al: Si: Ni = 0.2: 0.5: 1: 1: 1.

Embodiment 3

[0056] This embodiment provides a light hard Cocralsini high entropy alloy and a preparation method thereof, based on the light hard Cocralsini high entropy alloy and its preparation method thereof, the difference is only: light hard Cocraalsini high entropy alloy Atom ratio CO: CR: Al: Si: Ni = 0.2: 1: 1: 0.3: 1.

[0057] Character method:

[0058] The light hard Cocralsini alloy obtained by Example 1-3 was high entropy alloy, and the Aquiimed drainage method was used for density calculation;

[0059] Epoxy resin is delayed by the light hard Cocralsini high entropy alloy obtained by Example 1-3, and the resin gum substrate ratio is A: B = 2: 1, and the mold is placed in a vacuum drying box after mixing. Slowly solidify for a period of time, grind the same sample of the harder, respectively.

[0060] The test hardness of the TMVP-1 micro-hardness meter is used for the polished sample, which is 1.961N (200GF), which is 15 s; 8 different locations are selected for each sample. Hardn...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com