Waterproof coating material and preparation method thereof

A waterproof coating, water-based resin technology, applied in anti-corrosion coatings, fire-resistant coatings, polyurea/polyurethane coatings, etc., can solve the problems of mold, odor, pollute the indoor environment, etc., and achieve improved coating performance, low volatility, and increased hardness. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

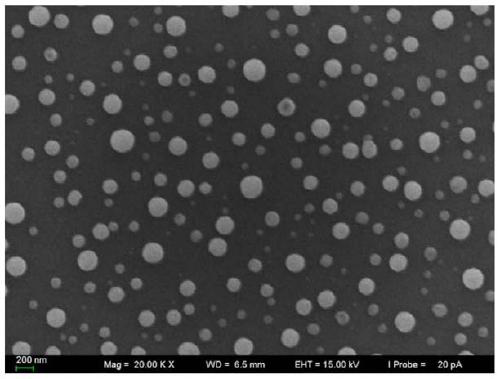

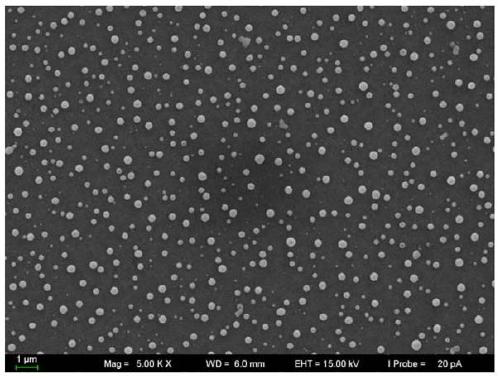

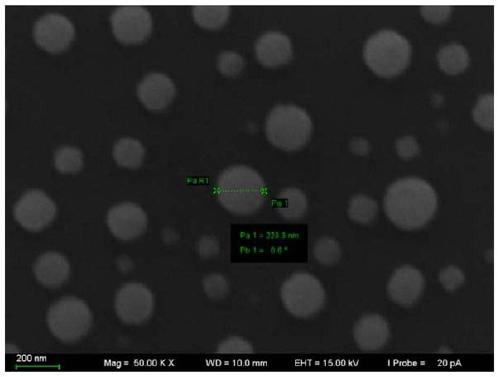

Image

Examples

Embodiment 1

[0043] A waterproof coating, which is composed of component A and component B according to a mass ratio of 1:4, wherein component A includes the following components and parts by mass:

[0044] 15 parts of polyisocyanate prepolymer, in the present embodiment 1, polyisocyanate prepolymer is Bayhydur XP 2655, can also use Bayhydur XP 3100 or Bayhydur 2319 of course; A low-molecular-weight polymer produced by the reaction of hydroxyl compounds. This prepolymer can be quickly dispersed in water and has a low viscosity, which is beneficial to improve the coating performance of the coating, has storage stability and low volatility;

[0045] 0.05 part of defoamer, in this embodiment 1, defoamer is BYK-028, of course BYK-024 can also be used;

[0046] 5 parts of propylene glycol diacetate;

[0047] Described B component comprises following component and mass parts:

[0048] 25 parts of water-based resin A, in the present embodiment 1, water-based resin A is Bayhydrol A 2470, of cour...

Embodiment 2

[0070] A waterproof coating, which is composed of component A and component B according to a mass ratio of 1:4, wherein component A includes the following components and parts by mass:

[0071] 20 parts of polyisocyanate prepolymer, in the present embodiment 2, polyisocyanate prepolymer is Bayhydur 2319; Contain active isocyanate-NCO component and the low molecular weight polymer that reacts with the hydroxyl compound in the second component to generate, this The prepolymer can be quickly dispersed in water, has a low viscosity, is beneficial to improve the coating performance of the coating, has storage stability and low volatility;

[0072] 0.7 part of defoamer, in the present embodiment 2, defoamer is BYK-024;

[0073] 10 parts of propylene glycol diacetate;

[0074] Described B component comprises following component and mass parts:

[0075] 30 parts of water-based resin A, in the present embodiment 2, water-based resin A is Bayhydrol A 145, is the water dispersion syste...

Embodiment 3

[0096] A waterproof coating, which is composed of component A and component B according to a mass ratio of 1:4, wherein component A includes the following components and parts by mass:

[0097] 25 parts of polyisocyanate prepolymers, in the present embodiment 3, polyisocyanate prepolymers are Bayhydur XP 3100; Contain active isocyanate-NCO component and the low molecular weight polymer that the hydroxyl compound of component B reacts to generate, this The prepolymer can be quickly dispersed in water, has a low viscosity, is beneficial to improve the coating performance of the coating, has storage stability and low volatility;

[0098] 0.1 part of defoamer, in the present embodiment 3, defoamer is BYK-024;

[0099] 15 parts of propylene glycol diacetate;

[0100] Described B component comprises following component and mass parts:

[0101] 35 parts of water-based resin A, in the present embodiment 3, water-based resin A is Bayhydrol A 145, is the water dispersion system that p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com