Method for self-staining catalytic synthesis of degradable polyester material

A technology for degrading polyester and polyester materials, applied in the field of polymer materials, can solve the problems of increasing process steps and increasing costs, and achieves the effects of simple synthesis process, high utilization rate and low cost of raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

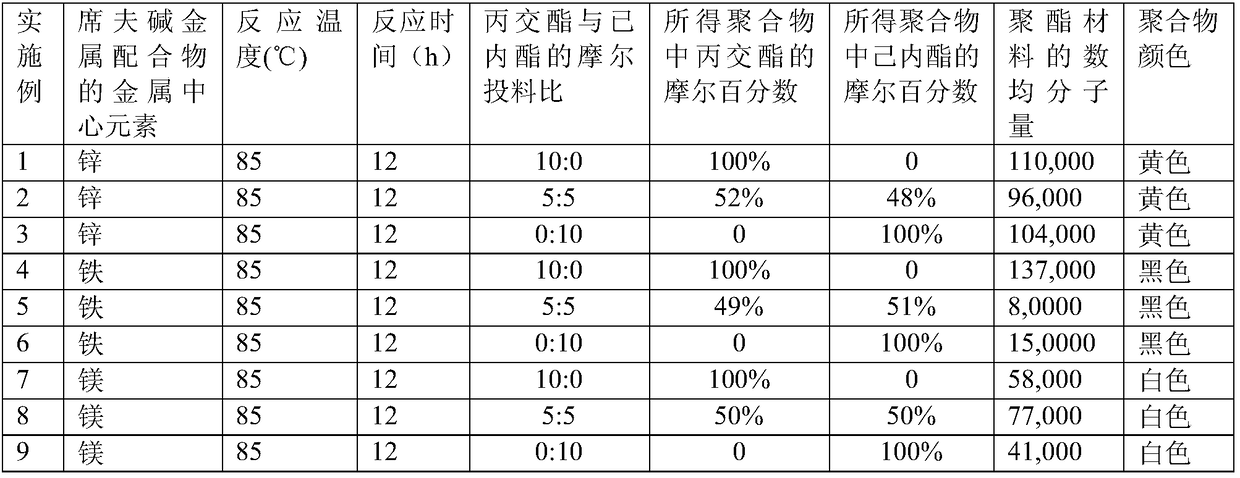

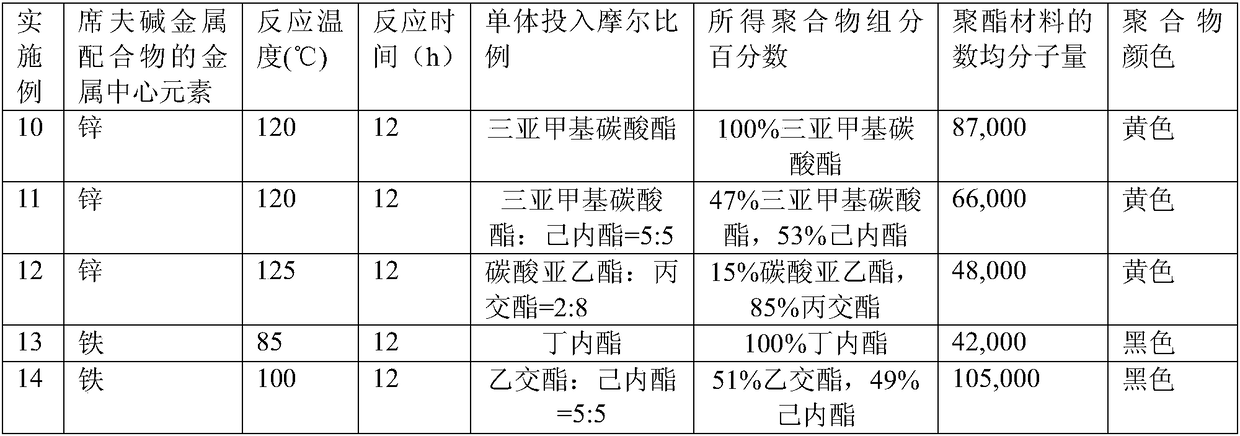

Examples

Embodiment Construction

[0019] The present invention will be further elaborated below by means of specific examples and combinations, but it should not be understood as limiting the protection scope of the present invention. Those skilled in the art can make some non-essential changes and adjustments according to the contents of the above invention, which all belong to the present invention. protected range.

[0020] In the method of the present invention, the Schiff base metal complex and one or two monomers are put into a reaction kettle, vacuumized and nitrogen filled for three times, then stirred and heated to a set temperature to start polymerization. After the polymerization reaction is over, the polymerization product in the reactor is taken out, and samples are taken for relevant structure and performance tests. The polymerization product is a self-dyed degradable polyester material, and the monomer conversion rate reaches more than 95%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com