Preparation method for silicon dioxide supported cationic alkyl polyglucoside type pour depressant of crude oil

An alkyl glycoside type, alkyl glycoside technology, applied in chemical instruments and methods, drilling compositions and other directions, can solve the problems of high equipment investment, difficulty in stopping and restarting, waste of energy, etc., and achieves easy access to raw materials, The preparation process is simple and the effect of reducing pour point is remarkable.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

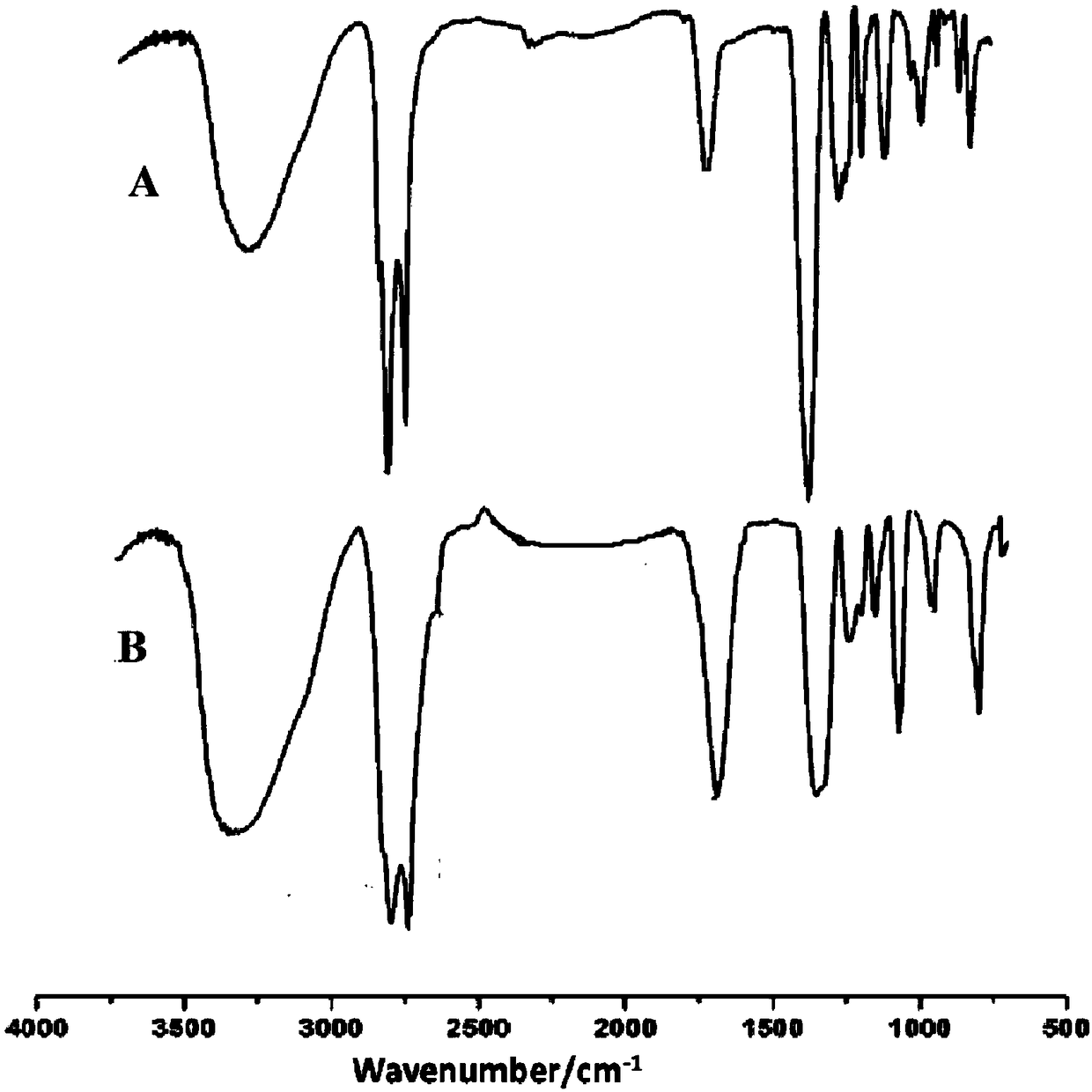

[0026] (1) At room temperature, dissolve 100 g of 50% cationic alkyl glycoside (CAPG-12143) in 200 g of ethanol solution with a volume fraction of 80%, add 1 g of saturated ammonium chloride solution, and stir for 1 hour to obtain a mixed solution;

[0027] (2) Add 150 g of tetraethyl orthosilicate dropwise to the mixture obtained in step (1), continue stirring until precipitation occurs, then raise the temperature to 80-90°C, continue stirring for 10 hours, filter, and wash with absolute ethanol , and then washed with deionized water, and vacuum-dried to obtain a solid;

[0028] (3) After grinding the solid obtained in step (2) into powder, it was calcined at 500°C for 8 hours to obtain a light yellow powder (112g), which is the CAPG-SiO 2 Nanomaterials (hereinafter referred to as Product A).

Embodiment 2

[0030] (1) At room temperature, dissolve 100 g of 50% cationic alkyl glycoside (CAPG-08143) in 300 g of ethanol solution with a volume fraction of 70%, add 5 g of saturated ammonium chloride solution, and stir for 0.5 h to obtain a mixed solution;

[0031] (2) Add 200 g of tetraethyl orthosilicate dropwise to the mixture obtained in step (1), continue stirring until precipitation occurs, then raise the temperature to 80-90°C, continue stirring for 12 hours, filter, and wash with absolute ethanol , and then washed with deionized water, and vacuum-dried to obtain a solid;

[0032] (3) After grinding the solid obtained in step (2) into powder, it was calcined at 600°C for 6h to obtain a light yellow powder (128g), which is the CAPG-SiO 2 Nanomaterials (hereinafter referred to as Product B).

Embodiment 3

[0034] (1) At room temperature, dissolve 100 g of 50% alkyl glycoside (APG-1214) in 200 g of ethanol solution with a volume fraction of 80%, add 1 g of saturated ammonium chloride solution, and stir for 1 hour to obtain a mixed solution;

[0035] (2) Add 150 g of tetraethyl orthosilicate dropwise to the mixture obtained in step (1), continue stirring until precipitation occurs, then raise the temperature to 80-90°C, continue stirring for 10 hours, filter, and wash with absolute ethanol , and then washed with deionized water, and vacuum-dried to obtain a solid;

[0036] (3) Grinding the solid obtained in step (2) into powder, and then calcining at 500° C. for 8 hours to obtain a solid powder (hereinafter referred to as product C).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com